speaker module

A loudspeaker module and loudspeaker technology, applied in the field of acoustics, can solve the problems of weakened sound absorption, failure, and the inability of long-term use of sound-absorbing materials for loudspeakers, so as to avoid the degree of adsorption and ensure the effect of acoustic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

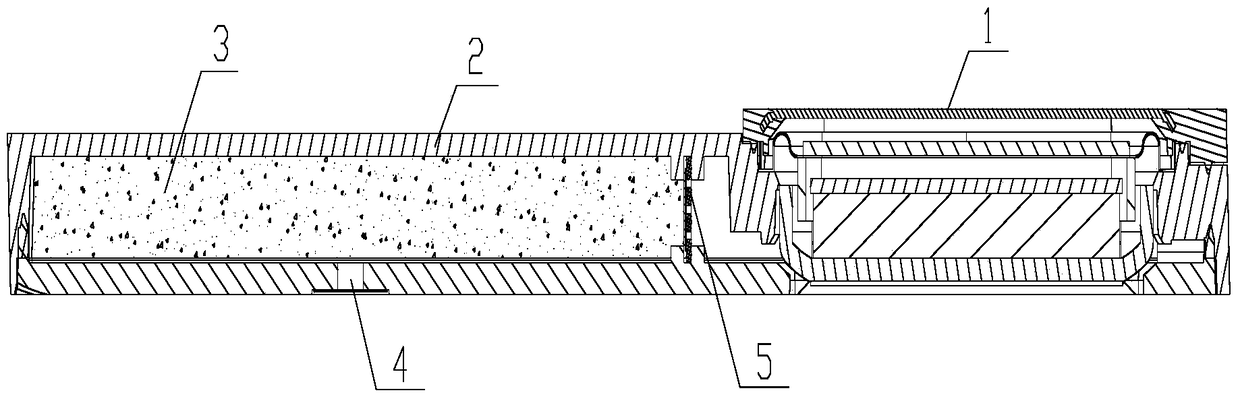

[0041] diagram 2-1 Shows the sectional structure of the loudspeaker module according to Embodiment 1 of the present invention; Figure 2-2 The top view structure of the speaker module according to Embodiment 1 of the present invention is shown.

[0042] Such as diagram 2-1 and 2-2 Commonly shown, the speaker module of Embodiment 1 of the present invention includes a housing 2, a speaker unit housed in the housing 2, and a sound hole is arranged on the housing 2, in order to expand the size of the speaker magnetic circuit system, a The steel sheet 1 is injection-molded on the body 2, and the loudspeaker unit is housed in the cavity formed by the shell 2 and the steel sheet. The front acoustic cavity communicates with the sound outlet, and the rear acoustic cavity is sealed; Damping hole, the housing 2 is provided with a damping net at the position corresponding to the damping hole to prevent small particles from the outside from entering the interior of the speaker unit, a...

Embodiment 2

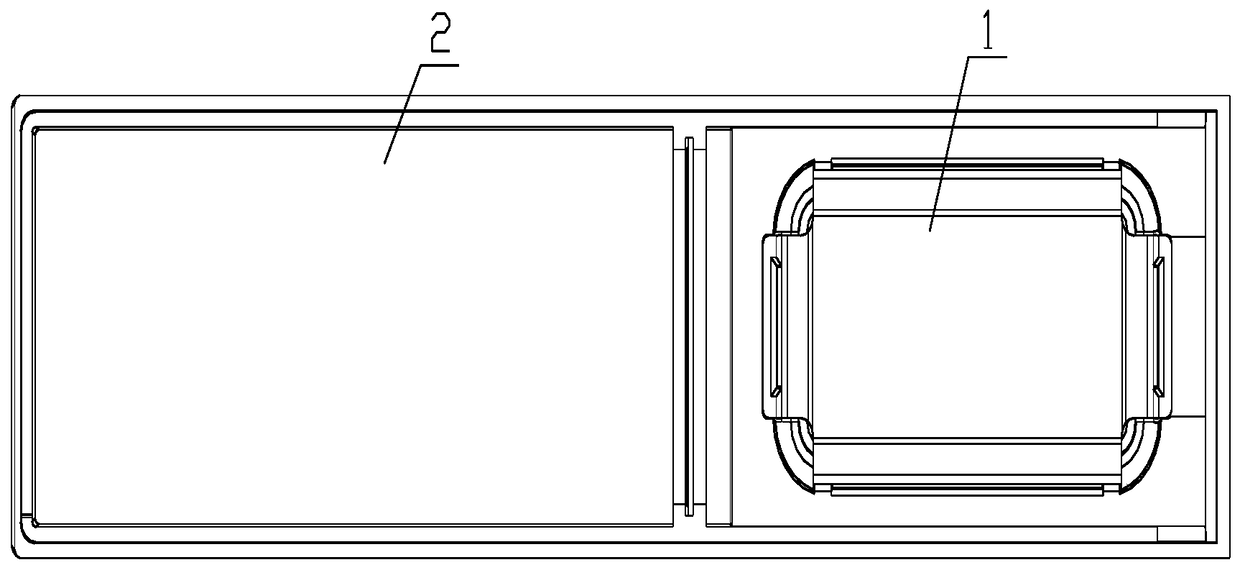

[0053] Figure 3-1 Shows the sectional structure of the loudspeaker module according to Embodiment 2 of the present invention; Figure 3-2 The top view structure of the speaker module according to Embodiment 2 of the present invention is shown.

[0054] Such as Figure 3-1 and 3-2 Commonly shown, the speaker module of the second embodiment of the present invention includes a housing 2', a speaker unit housed in the housing 2', and a sound hole is provided on the housing 2', in order to expand the size of the speaker magnetic circuit system A steel sheet 1' is injection molded on the shell 2', the front acoustic cavity is connected to the sound outlet, and the rear acoustic cavity is sealed; a damping hole is set on the shell 2' corresponding to the position of the rear acoustic cavity, and the shell 2' corresponds to the damping hole The position of the damping net is set to prevent small particles from the outside from entering the interior of the speaker unit, and at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com