An automatic capsule cap fitting machine

A technology of capsule caps and capsules, which is applied in the fields of capsule delivery, pharmaceutical formulation, drug delivery, etc. It can solve the problems of low production efficiency, heavy labor, high defective rate, etc., and achieve high integration rate, high production efficiency and high degree of automation , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

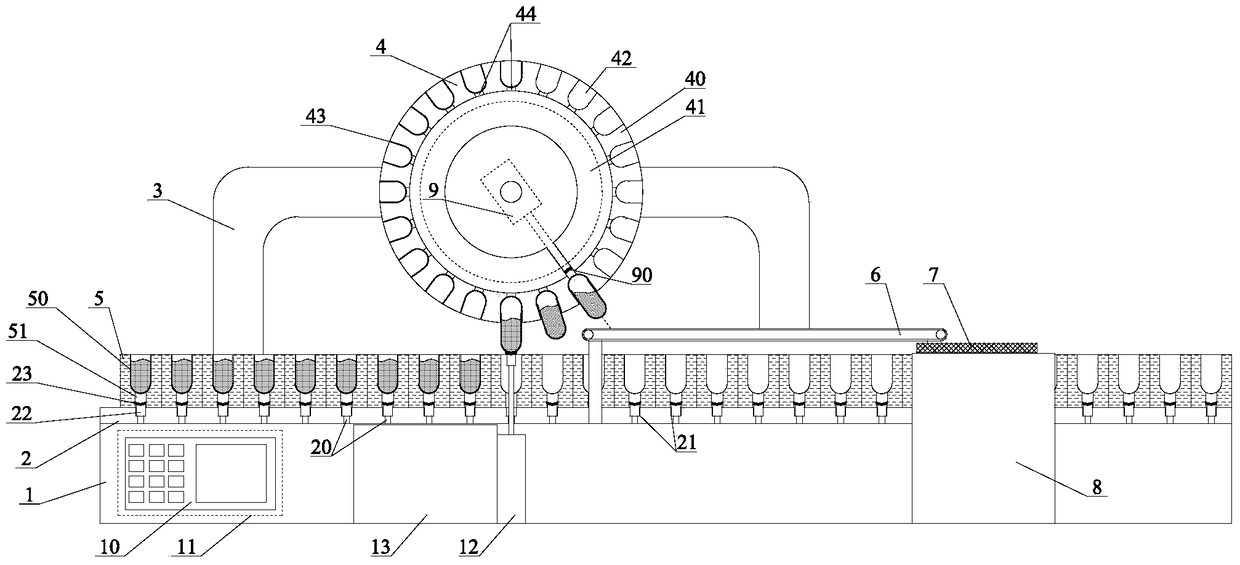

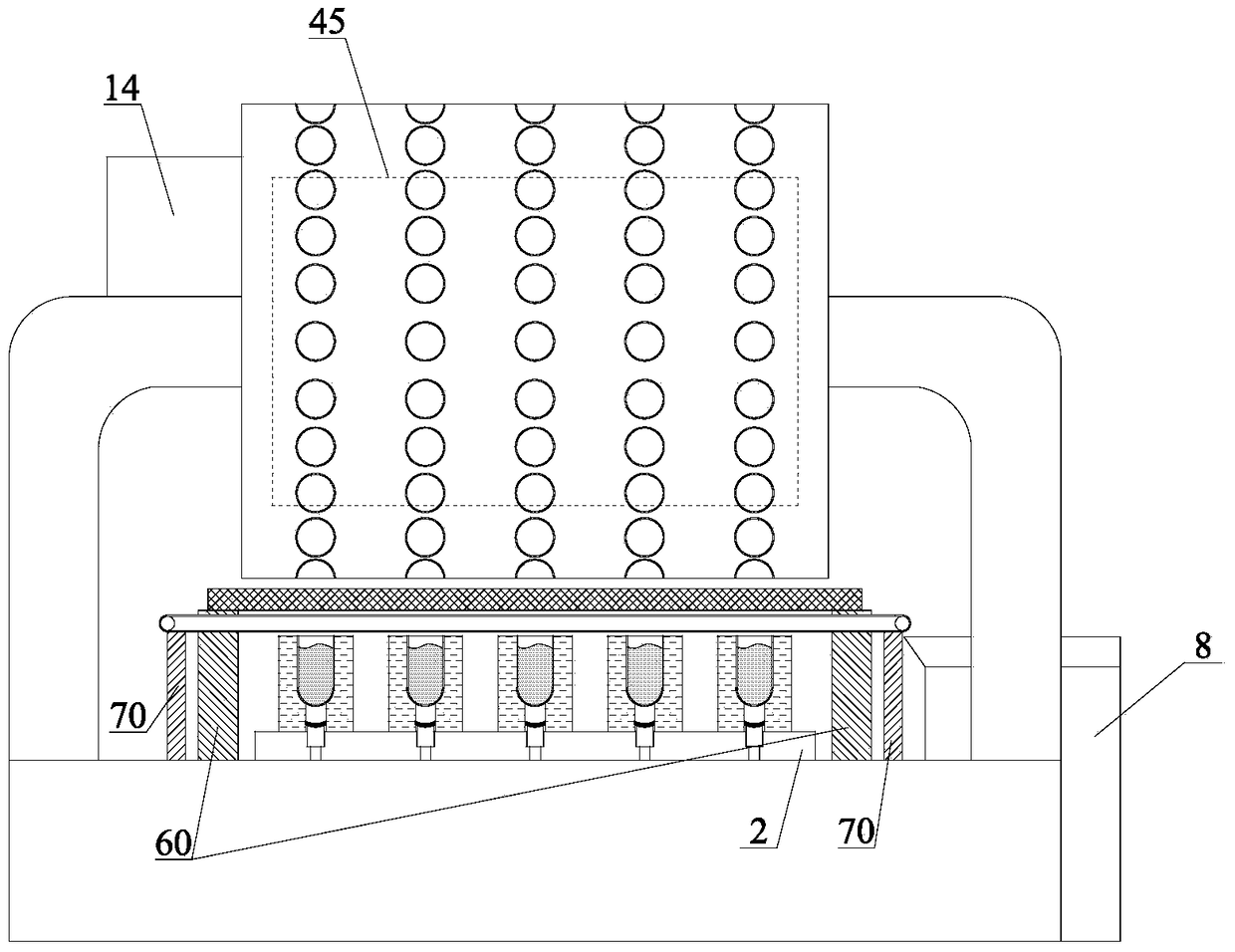

[0015] refer to figure 1 and figure 2 , an automatic capsule cap fitting machine of the present invention, comprising a machine base 1, a slide rail 2, a mounting bracket 3, a cylinder 4, a first conveyor belt 6, a second conveyor belt 7, a capsule box 8, a control device 11, a first Electric cylinder 12, second electric cylinder 9, a control panel 10 is installed on the outer surface of the base 1, the control panel 10 is connected to the control device 11 installed in the base 1, and the base 1 is also installed There are a first electric cylinder 12 and a first servo motor 13, the first servo motor 13 is connected to the first electric cylinder 12, a slide rail 2 and a mounting bracket 3 are installed above the base 1, and the slide rail 2 A capsule template 5 is installed on the capsule template 5, a capsule body 50 containing medicine is placed on the capsule template 5, a cylindrical tube 4 and a second servo motor 14 are installed on the mounting bracket 3, and the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com