One-piece plastic capping and capping equipment

A plastic cover and one-piece technology, which is applied in sorting and other directions, can solve the problems of low efficiency of manual closing and processing, affecting product hygiene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

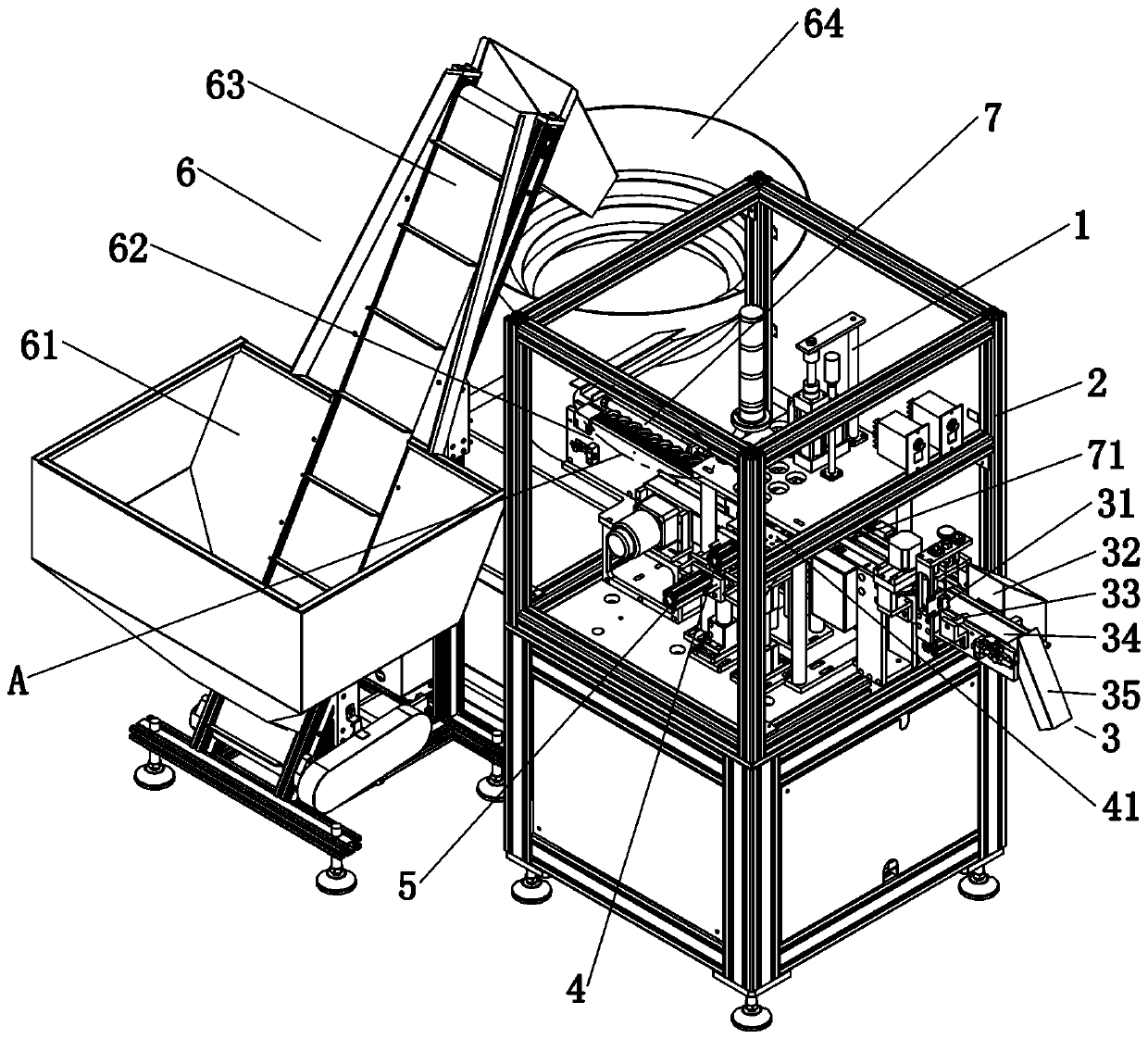

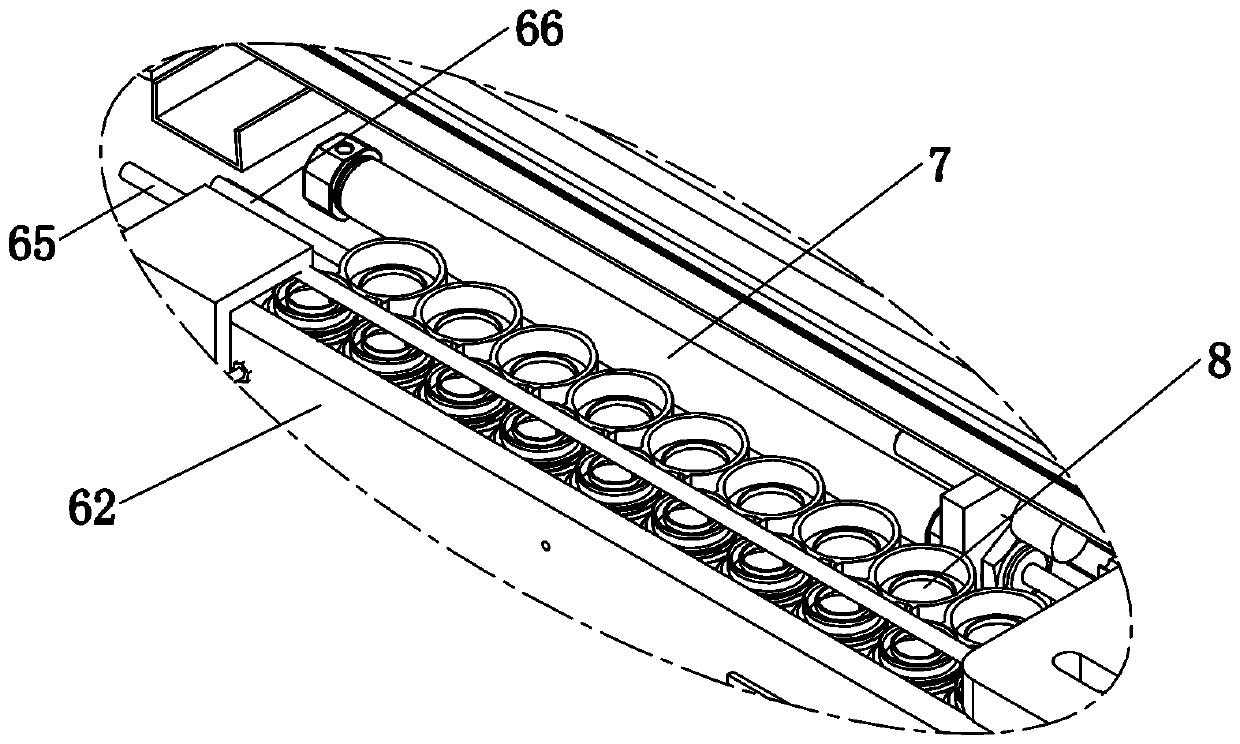

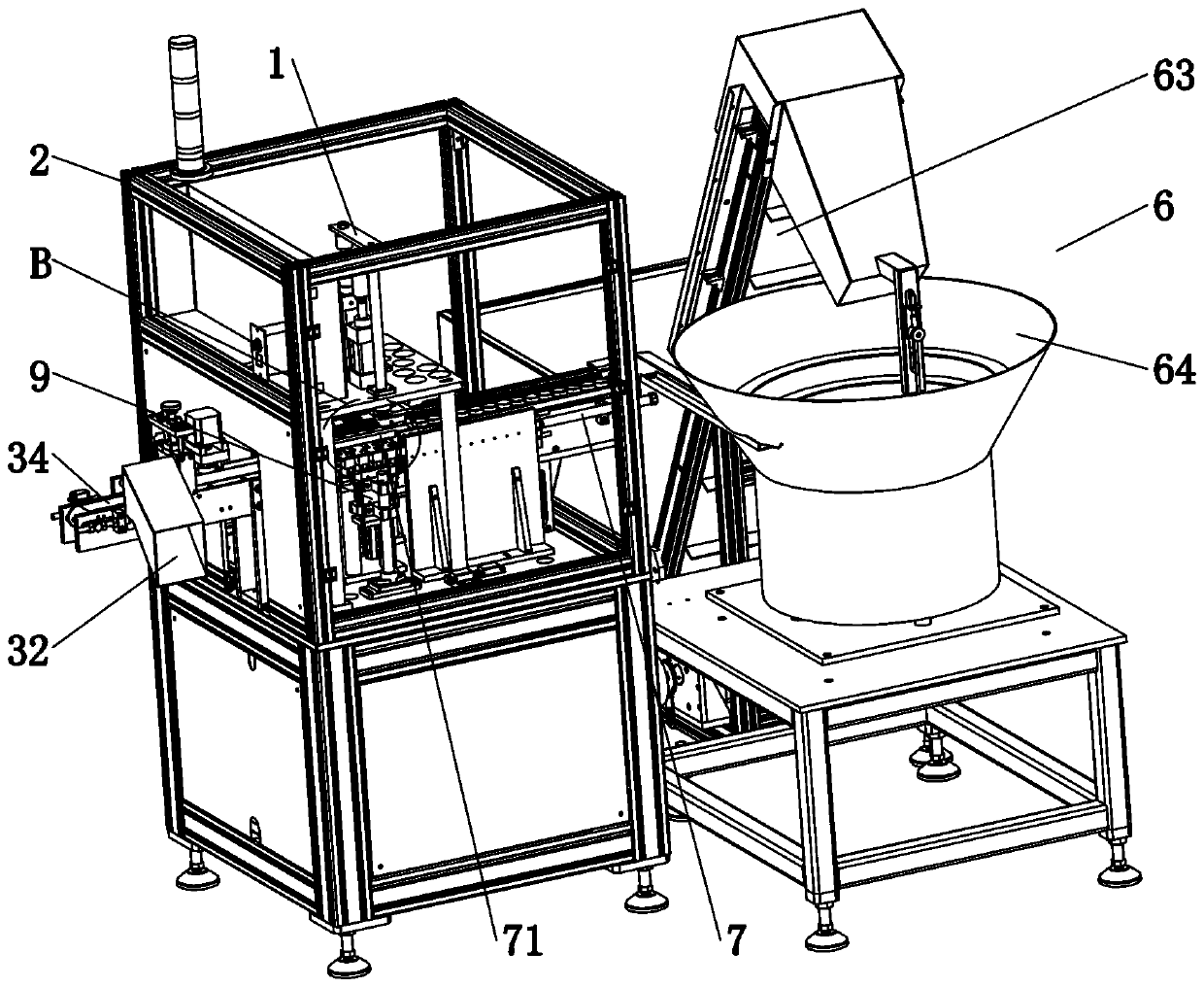

[0036] see Figure 1 to Figure 10 As shown, a one-piece plastic cover closing device, the one-piece plastic cover 8 includes a seat body 82 and a cover body 81 provided in one piece, and the front cover body 81 of the one-piece plastic cover 8 is opened (see Figure 10 shown); the lid closing equipment includes a frame 2, a feeding mechanism 6, a workbench 10 and a discharge mechanism 3, the workbench 10 is arranged on the frame 2, and the workbench 10 is arranged on the feed mechanism 6 and the discharge mechanism 3 Between the mechanisms 3, after the one-piece plastic cover 8 in the open state enters the workbench 10 through the feeding mechanism 6, the one-piece plastic cover 8 enters the discharge mechanism 3 after the cover is processed on the workbench 10, and the frame 2. The upper corresponding workbench 10 is provided with an anti-warping mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com