Shape following-up flexible heating device

A heating device and flexible technology, applied in lighting and heating equipment, metal processing equipment, combustion methods, etc., can solve the problems of unfavorable combustion of gas, pollution of workpieces, low calorific value, etc., and achieve uniform and adjustable combustion temperature and complete combustion , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

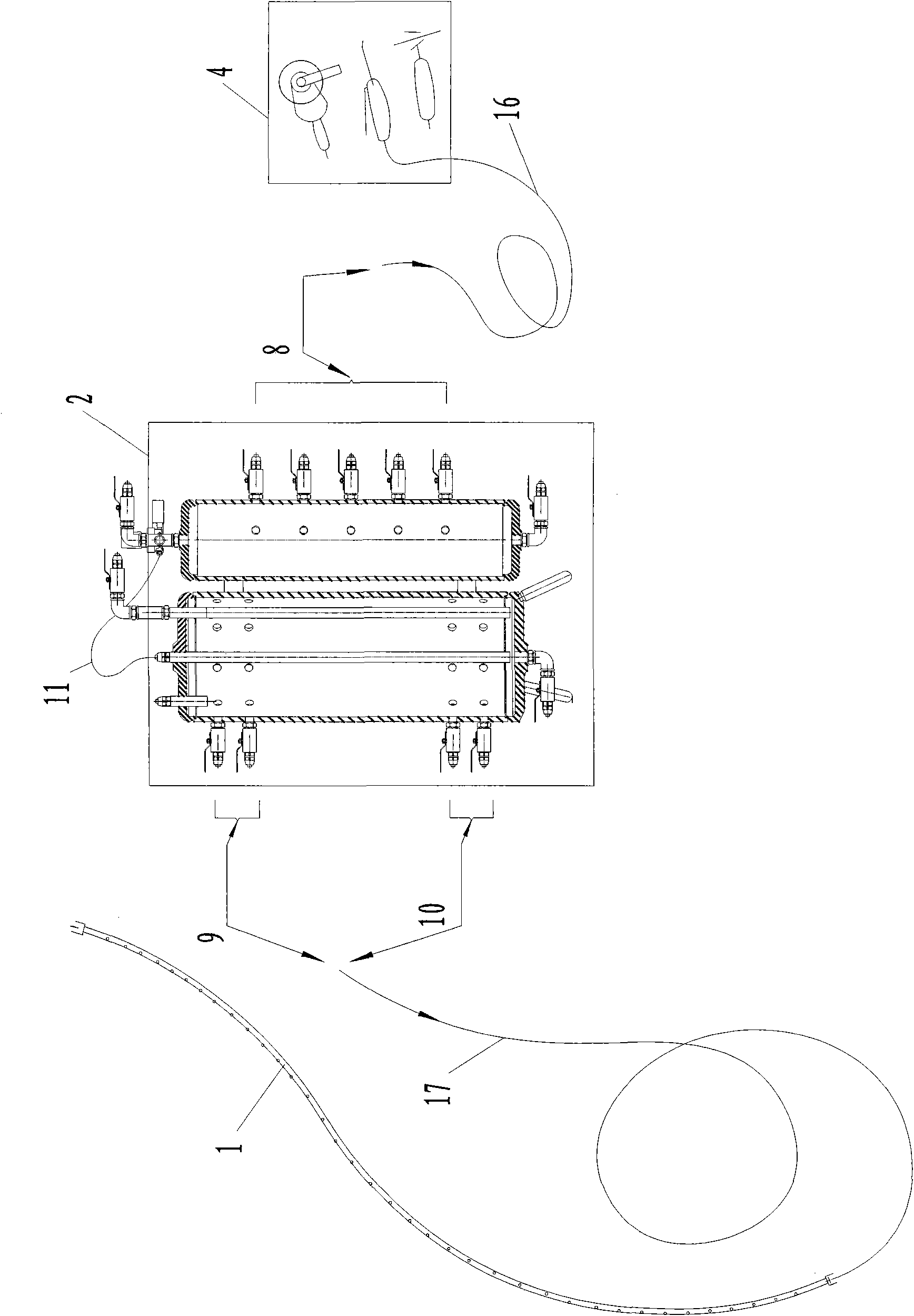

[0056] Refer to the attached figure 1 and 1a , the invention discloses a conformal flexible heating device, comprising a flexible heating tube 1 and a gas mixing mechanism,

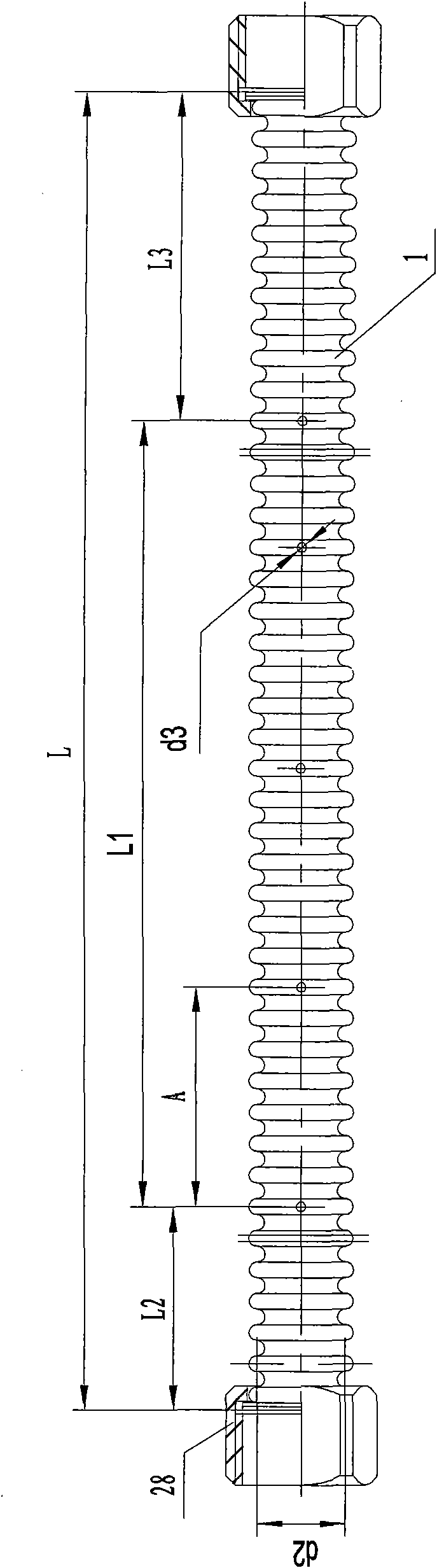

[0057] The flexible heating tube includes a pipe body, the diameter of the pipe body is 15-20 mm, and the length of the pipe body is 500-10000 mm. section, the fire spray section is evenly distributed with a plurality of fire spray holes along the same side of the pipe length direction, the diameter of the fire spray holes is 1-1.5 mm, and the sum of the hole areas of all fire spray holes is less than the diameter cut-off of the pipe body area;

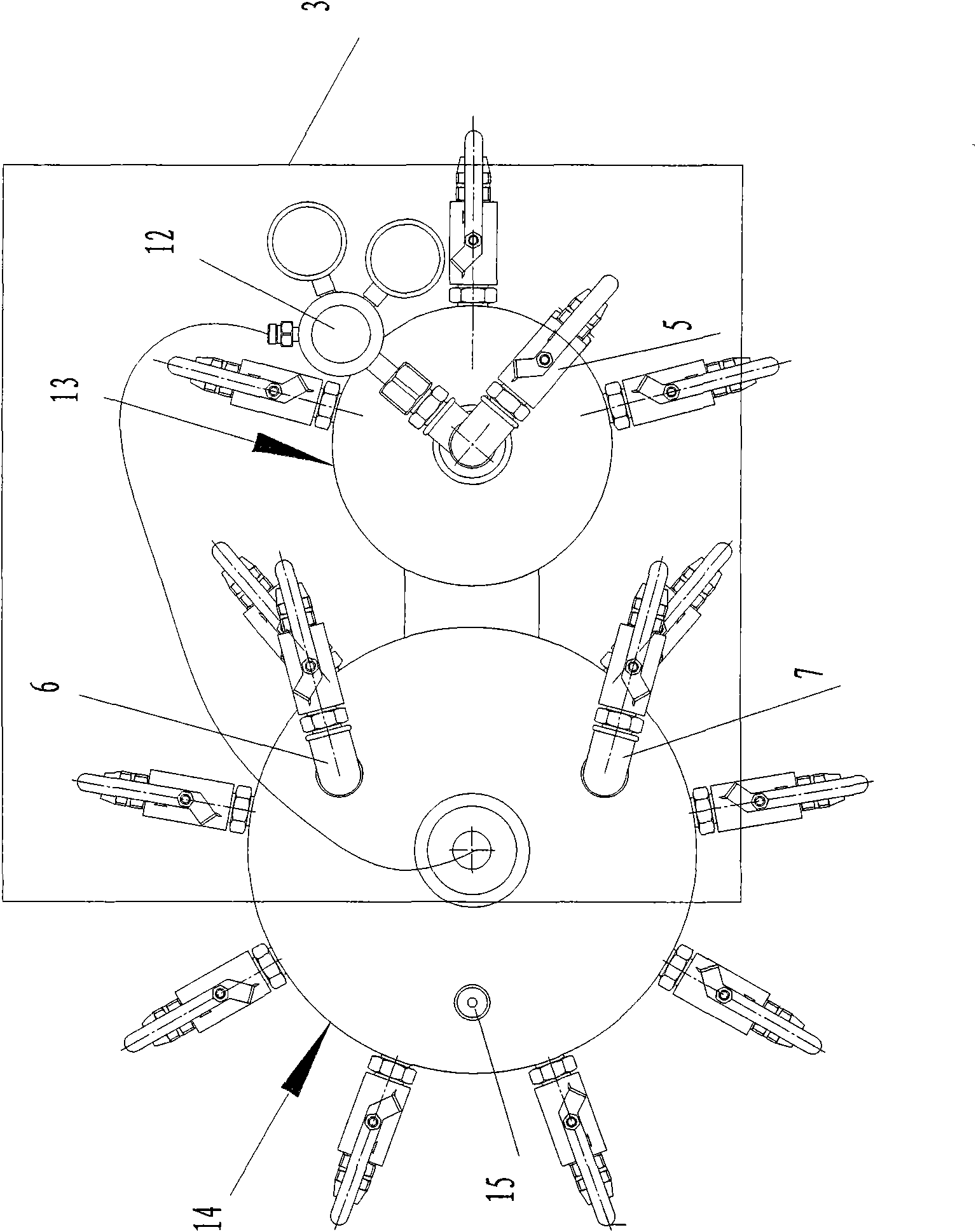

[0058] The air mixing mechanism includes a compressed air tank 13 and an air mixing tank 14, a compressed air input valve 5 and a compressed air pressure reducing valve 12 are arranged on the top of the compressed air tank 13, and compressed air tanks are provided around the compressed air tank 13. Output valve 8; a light gas input valve 6 and a heavy gas inpu...

Embodiment 2

[0064] The flexible heating pipe can be made of corrugated pipes of different diameters (generally the corrugated pipes with a diameter of 15 mm or 20 mm.) or pipes such as copper pipes or steel pipes with small rigidity, the length of which is between "500-10000" mm, and in between. According to the equal distance of "25-200" mm, the holes are evenly distributed along the same side of the pipe length direction. The diameter of the drill hole (generally choose "1-1.5" mm is better!) and the number of holes are determined according to the pipe diameter and pipe length. Generally, the sum of the hole areas of the drilled holes should be smaller than the diameter area of the selected pipe, so as to ensure that the flexible heating pipe has sufficient mixed gas or gas flow throughout the length of the pipe (pure gas combustion is not sufficient, energy consumption is large, Low calorific value, black smoke, pollute workpiece!). When manufacturing flexible heating pipes, the firs...

Embodiment 3

[0076] The gas+compressed air used in the present invention (gas can be light natural gas or other heavy liquefied gas), wherein the compressed air is divided into two paths of gas supply during use, and one path of compressed air passes through the gas mixing system 2 and the gas mixing tank 14 After the gas in the gas is mixed in a certain proportion, it is sent to the slender flexible heating tube by the gas output valve of the gas distribution system 3 to realize the complete combustion and heating function of the gas. Here, the light gas and heavy gas must be input through different gas The valve enters the gas mixing tank 14, and in one use, only one kind of gas is allowed to be input into the gas mixing tank 14, and multiple gases cannot be mixed and burned, otherwise it is difficult to realize the complete combustion of the combustible gas. Another way of compressed air directly enters the compressed air tank 13, and is sent to the auxiliary air (pneumatic) tools in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com