Steel wire rope regulating device used for output plate in printer

An adjustment device and steel wire rope technology, which is applied to general parts of printing machinery, printing machines, printing, etc., can solve the problems of easy slipping or shrinkage of steel wire ropes, poor stability, etc., and achieve good levelness, good repeatability, and firm locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

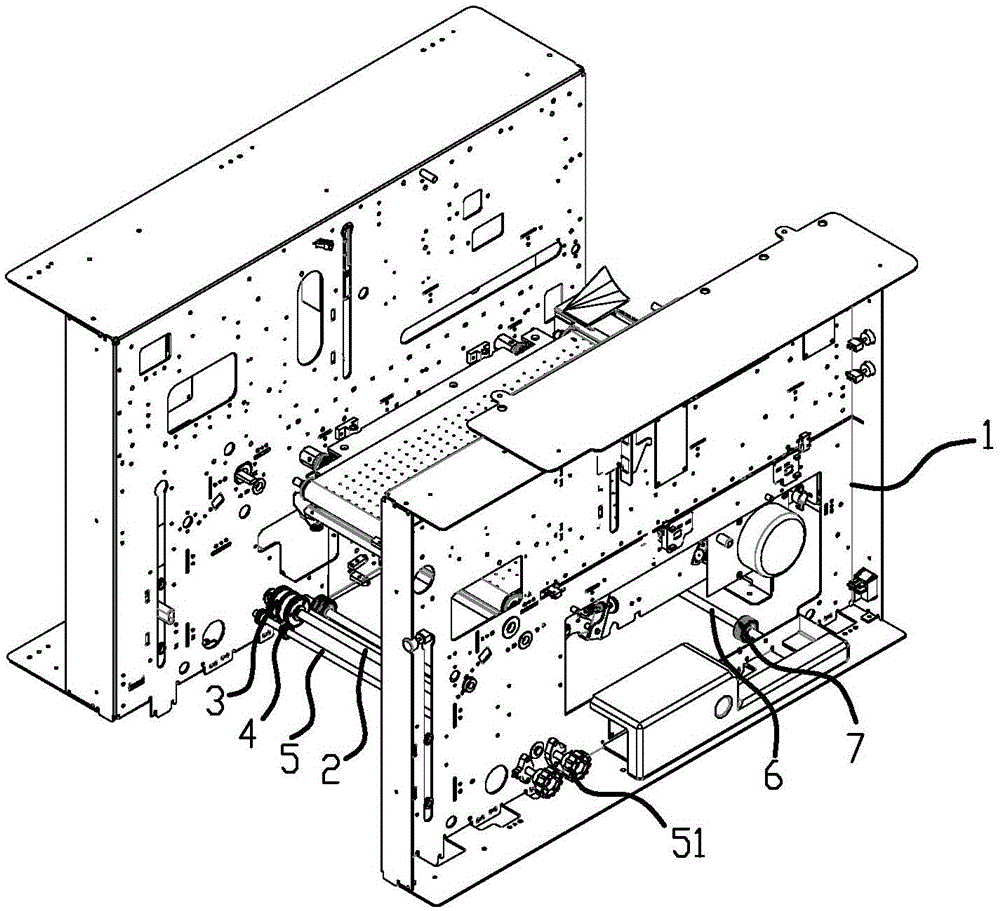

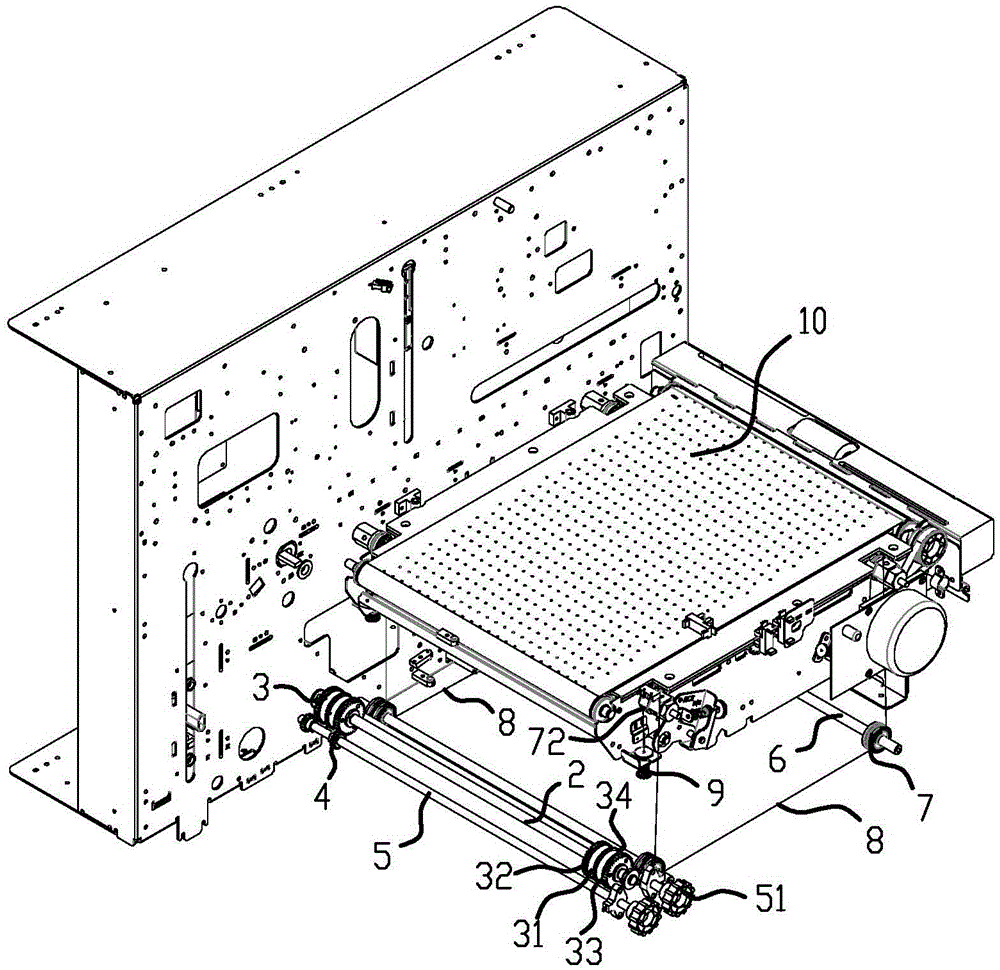

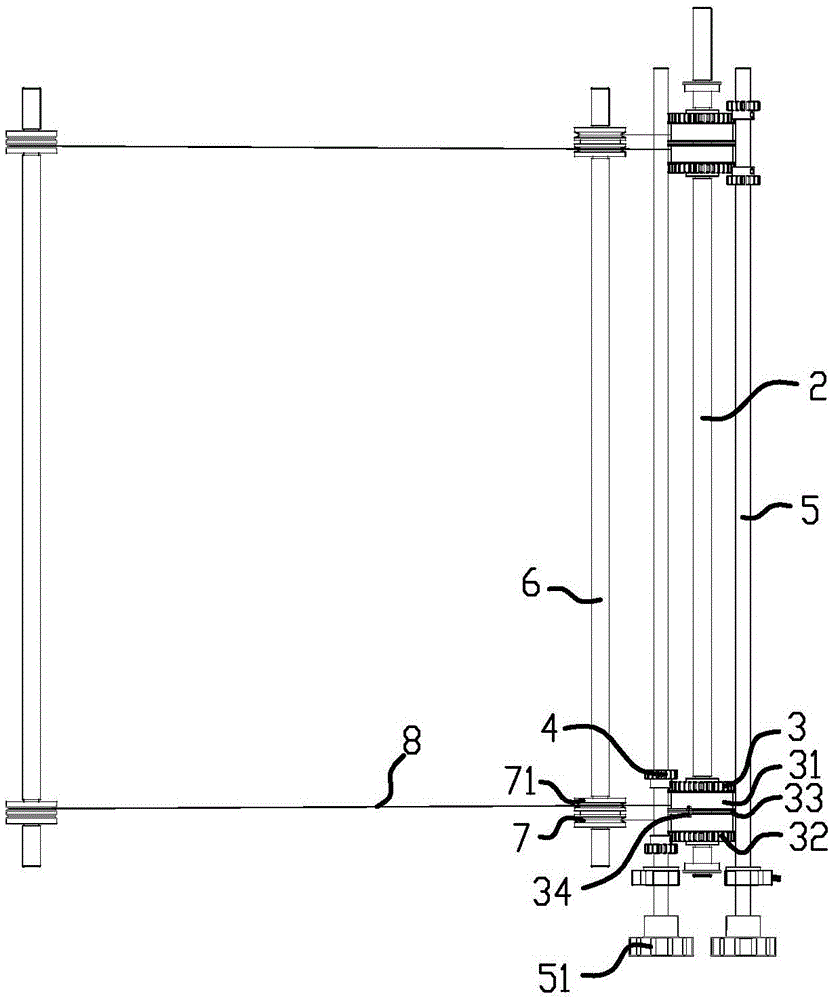

[0031] Such as figure 1 with figure 2 As shown, the wire rope adjusting device used for the output disc in the printing machine includes: a frame 1, on which a mounting shaft 2 is installed, and the frame 1 is composed of two oppositely arranged mounting frames, and the two ends of the mounting shaft 2 Installed on the mounting frame; one-way bearing 3, one-way bearing 3 are fixedly installed on the mounting shaft 2, one-way bearing 3 is provided with gear teeth 32; wire rope 8, wire rope 8 is wound on one-way bearing 3, wire rope 8 One end is fixedly connected to the one-way bearing 3 and the wire rope 8 can be wound on the one-way bearing 3. The one-way bearing 3 can drive the wire rope 8 to wind in one direction and the reverse s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com