Vertical resistance brake mounting bracket structure used for locomotive

A technology of resistance braking and mounting frame, applied in the direction of brakes, braking components, railway braking systems, etc., can solve the problems of poor sound insulation and noise reduction, inconvenient maintenance, etc., to facilitate maintenance, improve comfort, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

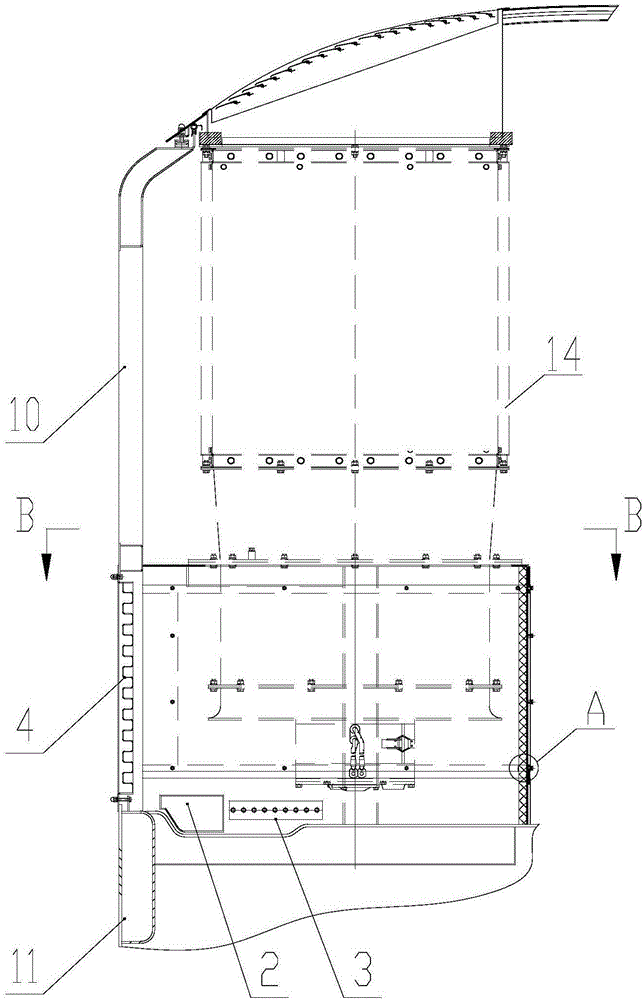

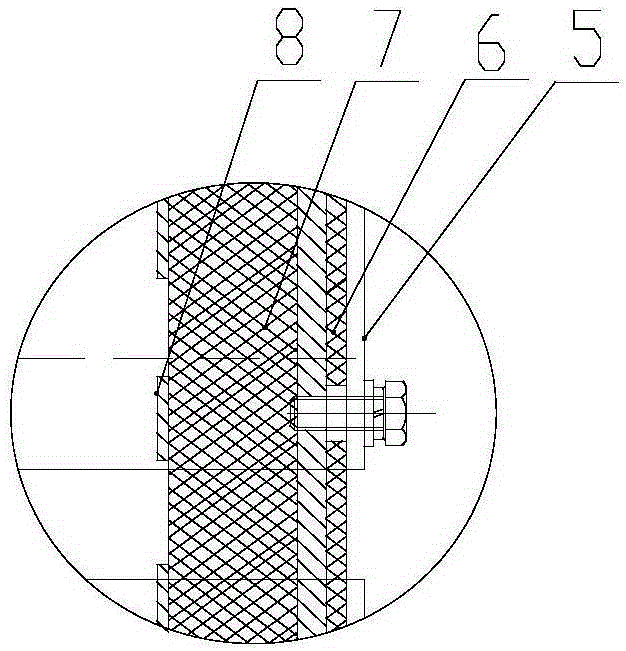

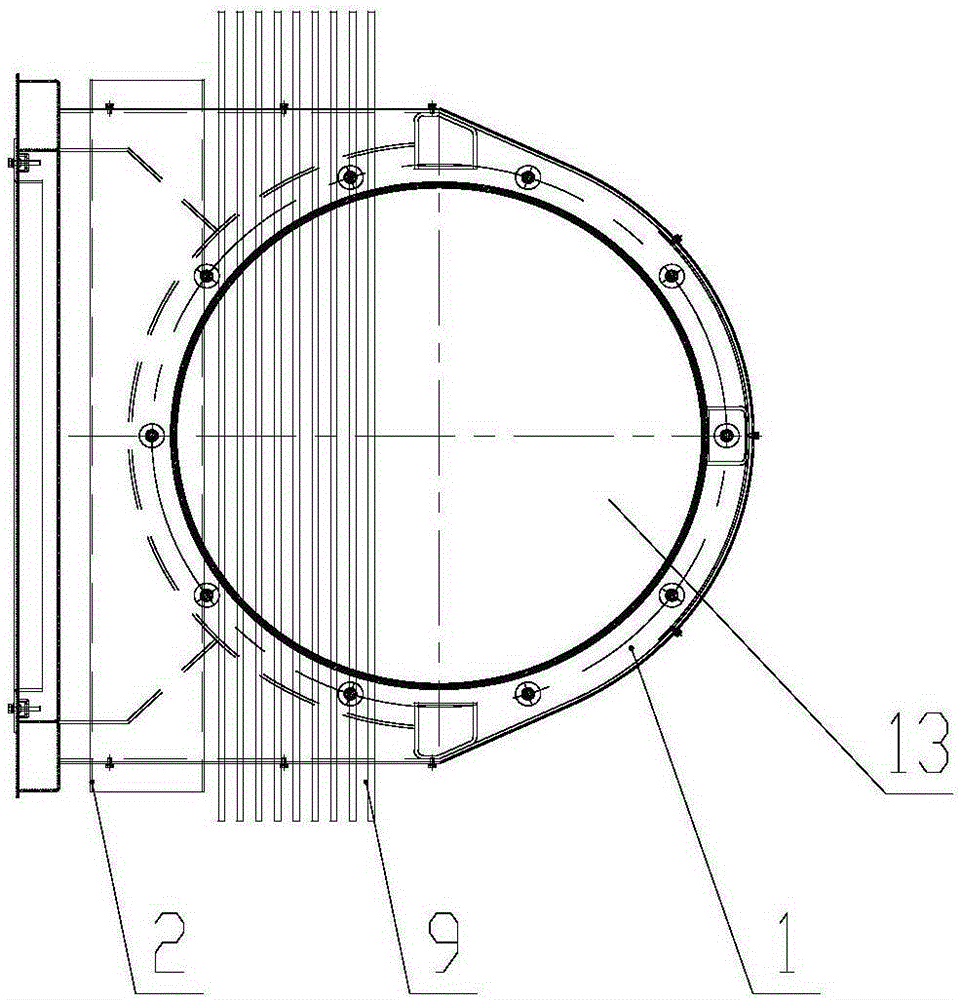

[0026] see Figure 1 to Figure 7 As shown, a vertical resistance brake mounting frame structure for a locomotive includes a resistance braking mounting frame 1, the bottom of the resistance braking mounting frame 1 is fixed on the locomotive chassis 11, and one end of the resistance braking mounting frame 1 is fixed on On the side wall 10 of the locomotive, the other end faces the middle corridor of the locomotive, and it is characterized in that it also includes a wiring trough 2 and a brake pipe row 9. The lower part passes through the resistance brake installation frame 1, and the wiring groove 2 and the brake pipe row 9 are perpendicular to the axis of the resistance brake installation frame 1, and the two ends of the wire groove 2 are welded with the resistance brake installation frame 1 Sealing, the two ends of the brake pipe row 9 are herme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com