a kink machine

A kinking machine and kinking technology, applied in the field of kinking machines, can solve the problems of inability to meet the needs of industrial production, low kinking efficiency, food hygiene, etc., and achieve the effects of ensuring food safety and hygiene, improving work efficiency, and improving food quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

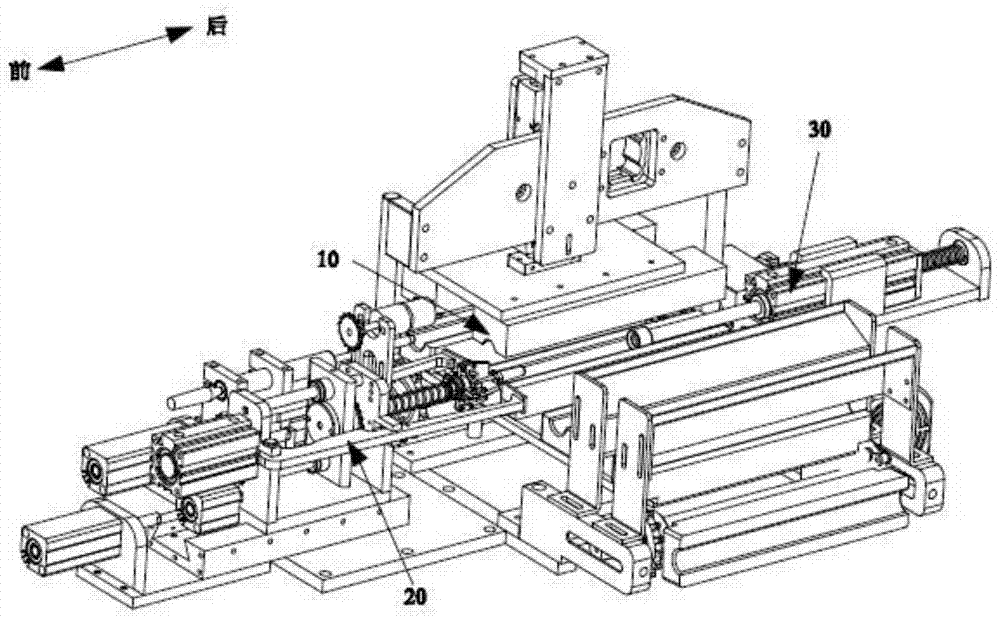

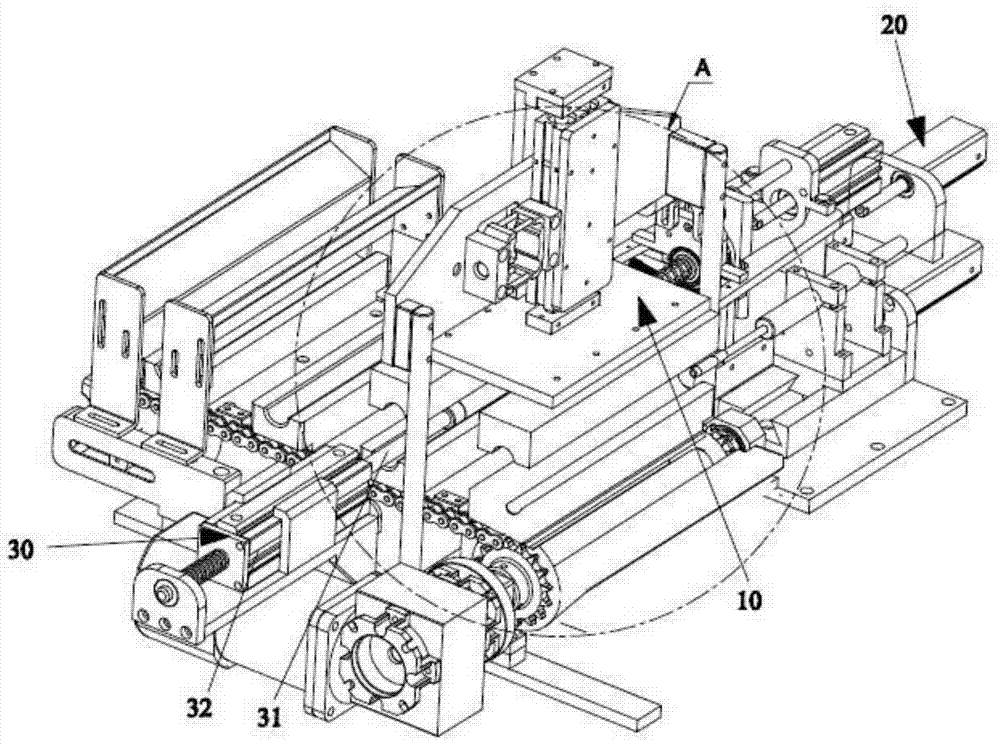

[0044] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a positioning device 10 , a kink device 20 and a push rod device 30 . The invention is suitable for the twisting operation of the shrunk casing before the enema, and can be matched with an automatic casing shrinking machine to produce well-twisted shrunken casings.

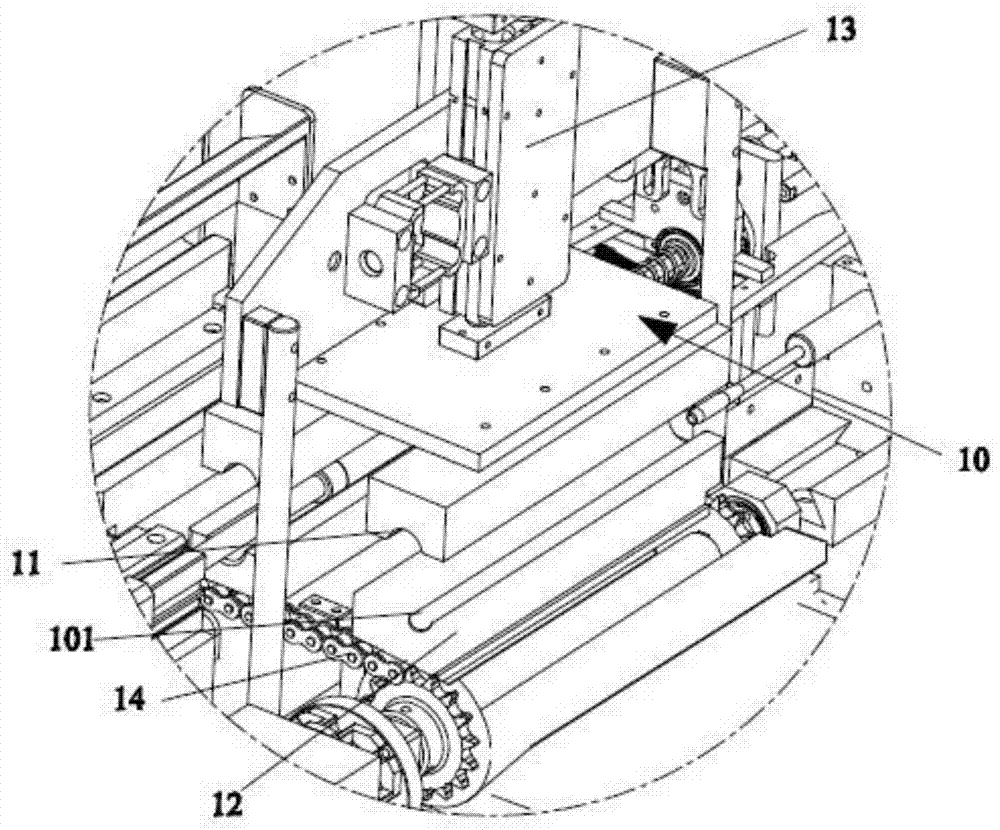

[0045] Wherein, the positioning device 10 is used to fix the shrunk casing. Such as image 3 As shown, the positioning device 10 includes an upper sleeve clamp 11 , a lower sleeve clamp 12 and a first cylinder 13 for driving the upper sleeve clamp 11 to move up and down. Both the upper sleeve clamp 11 and the lower sleeve clamp 12 have grooves 101, and the grooves 101 are semicircular. Collet clamp 11 descends, thereby with lower sleeve clamp 12, sleeve casing casing is fixed. In this embodiment, there are a plurality of lower sleeve clamps 12, which are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com