Bolt type safety guaranteeing structure for elevator

A safety guarantee, plug-type technology, applied in elevators, transportation and packaging, etc., can solve the problems that passengers cannot judge, cannot intuitively judge whether there are hidden dangers in the elevator, and cannot visualize elevator safety hazards, so as to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

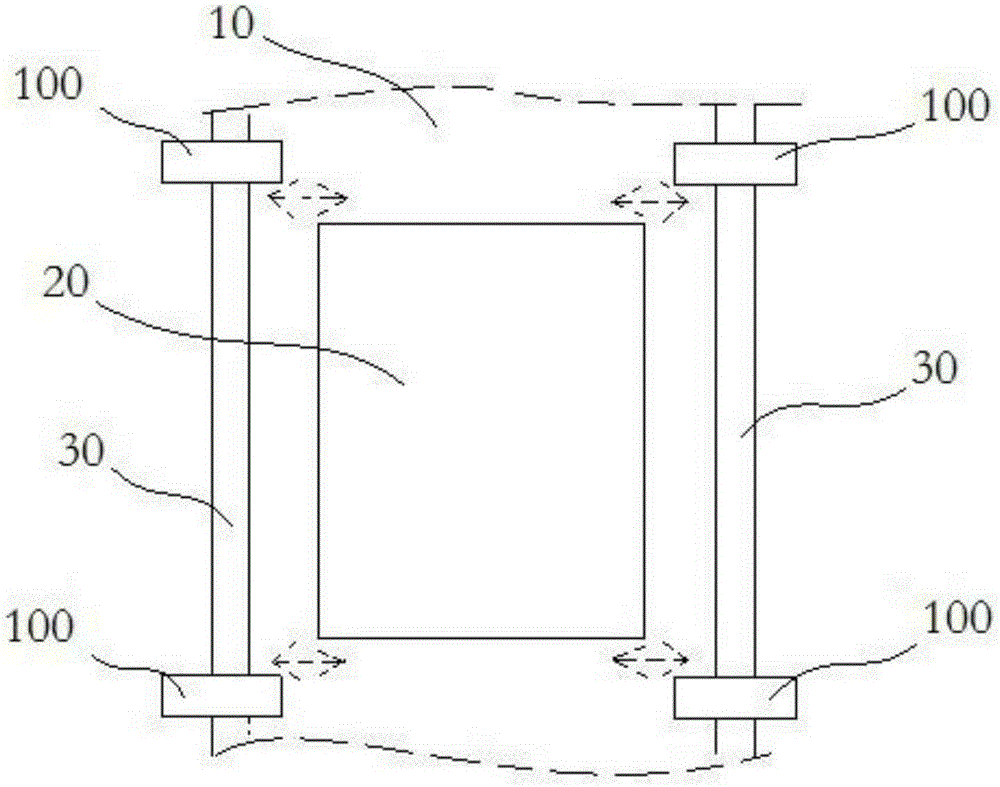

[0028] This embodiment discloses a bolt-type safety protection structure for elevators, see figure 1 , the safety guarantee structure is provided with four fixing pins 100, which are arranged symmetrically in pairs on the top and bottom of the elevator car 20 respectively. Four fixed pins 100 are placed inside the elevator shaft 10, and are fixedly arranged on the body of wall 30. Each fixed pin 100 is connected with a power mechanism (not shown in the figure), and the power mechanism drives the fixed pin 100 to move horizontally ( figure 1 The middle arrow indicates the moving direction of the fixing pin 100). During work, the power mechanism drives the fixed pins 100 to stretch out after the elevator car 20 reaches the floor and stops (before the elevator door is opened), and the four fixed pins 100 jointly limit the upward or downward movement of the elevator car 20; (after the elevator door is closed), when needs continue to rise or fall, the power mechanism drives four f...

Embodiment 2

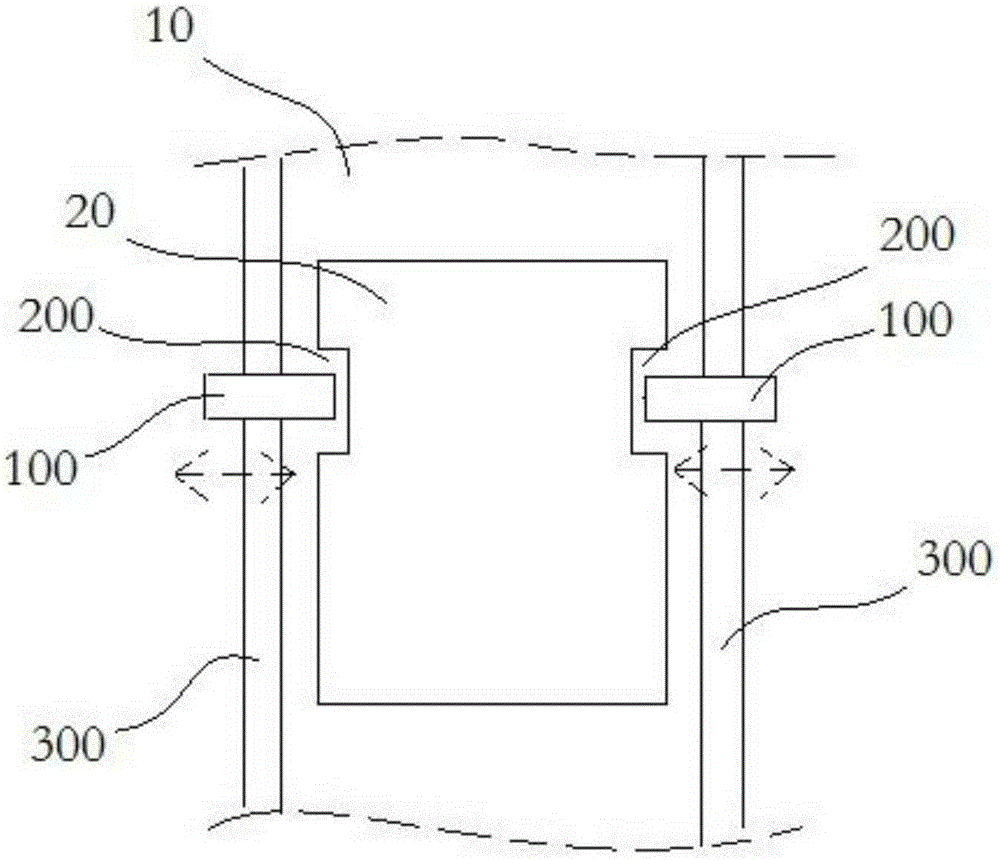

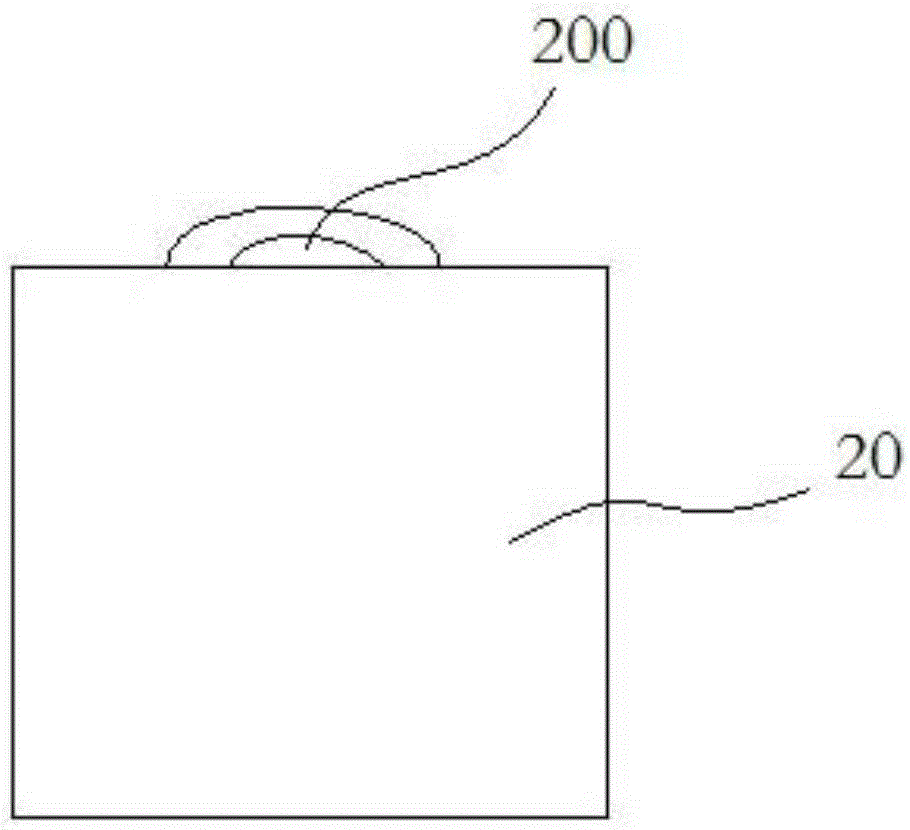

[0035] The function of this embodiment is basically the same as that of Embodiment 1. The difference is that in this embodiment, four grooves corresponding to the fixing pins 100 are provided on the top and bottom of the elevator car 20. After the four fixing pins 100 are stretched out, respectively Insert into the four grooves to realize the limit of the elevator car 20.

Embodiment 3

[0037] The function of this embodiment is basically the same as that of Embodiment 2. The difference is that the fixing pins 100 of this embodiment are respectively arranged on the top and the bottom of the elevator car 20, and the grooves are arranged on the wall 30, which are connected with the fixing pins 100. One to one correspondence.

[0038] In practical applications, eight fixing pins 100 can be provided, which are respectively placed at the four corners of the top and bottom of the elevator car 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com