Tower crane self-locking linkage table

A linkage platform and self-locking technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as difficult maintenance and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

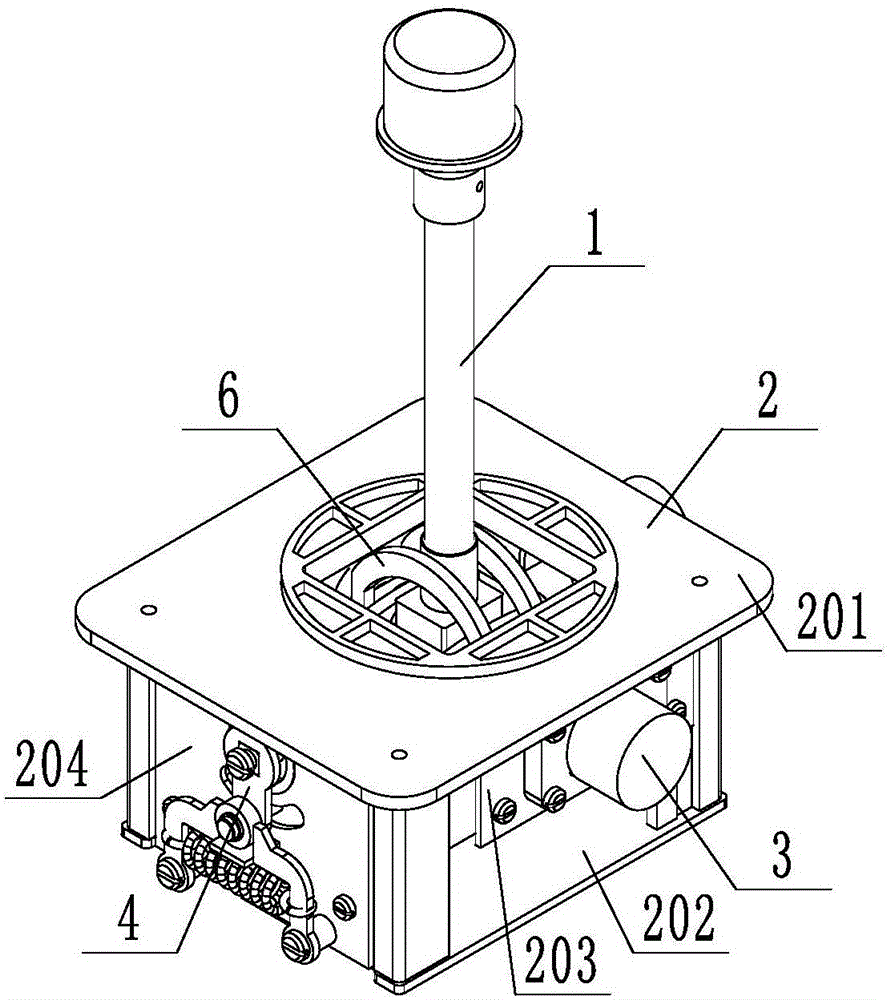

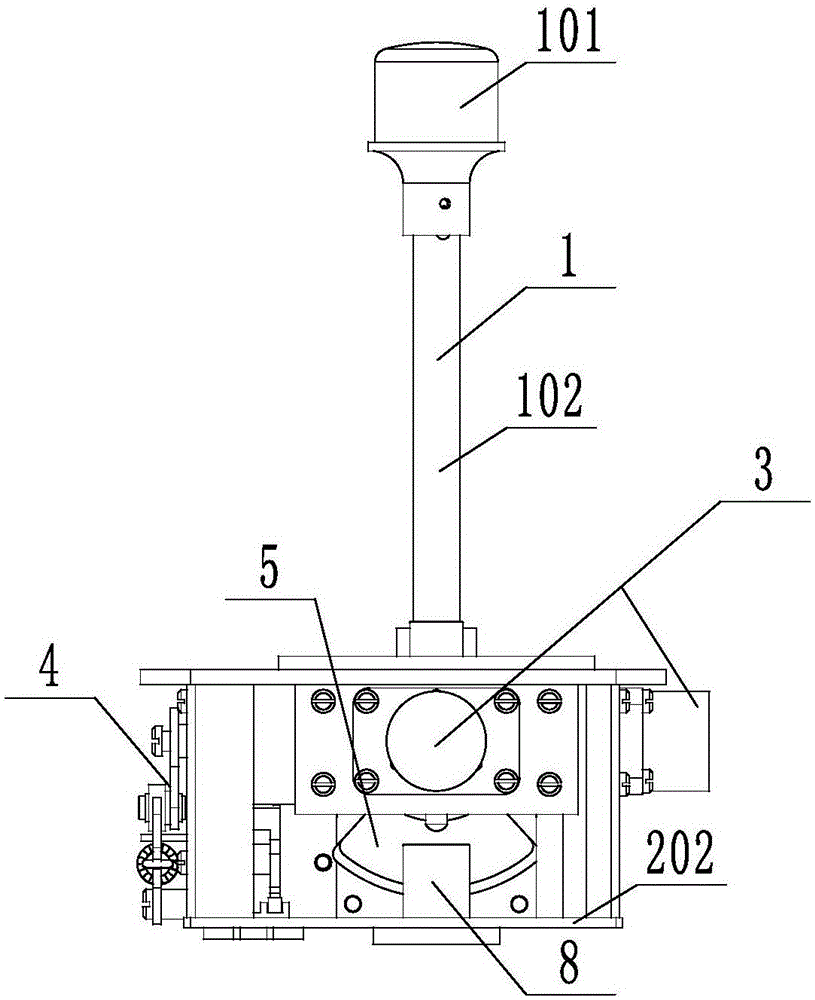

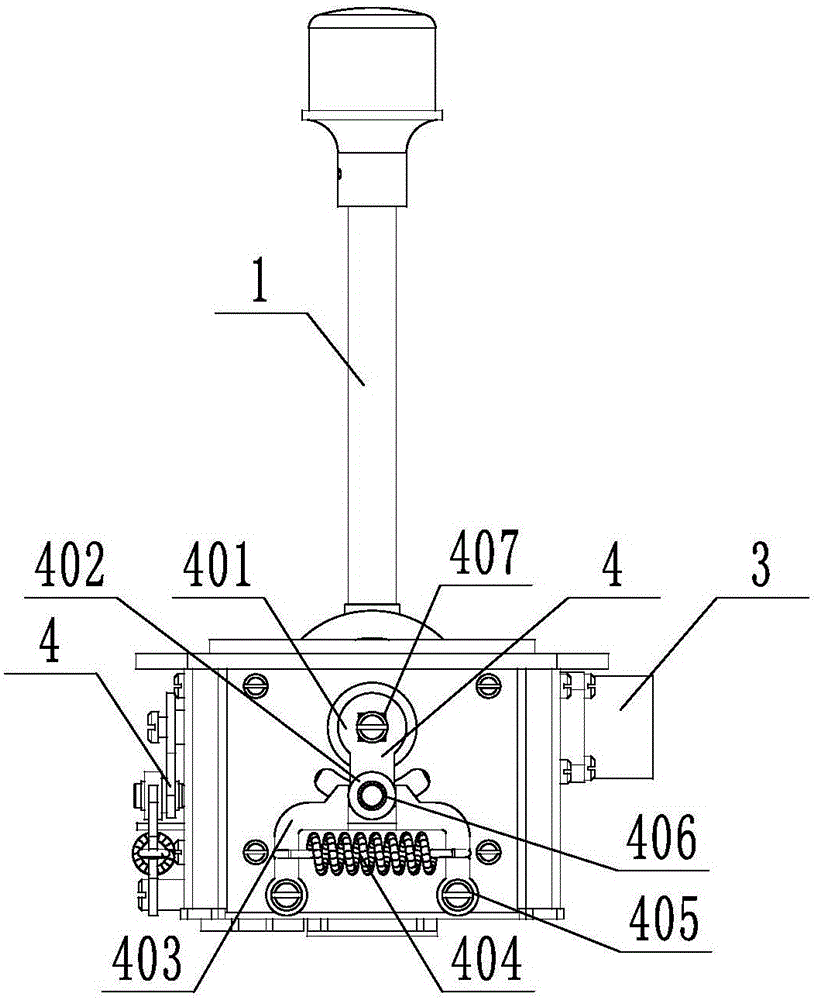

[0028] Such as Figure 1 to Figure 5 As shown, the tower crane self-locking linkage platform includes a handle 1, a box body 2, an angular displacement sensor 3, a reset mechanism 4, a cam group 5, a first transmission shaft 6, a second transmission shaft 7, a self-locking mechanism 8 and a controlled device9.

[0029] Such as Figure 7 with Figure 8 As shown, the handle 1 includes a handle head 101 and a handle rod 102, the handle rod 102 is a hollow rod, and the inner rod 804 of the self-locking mechanism 8 is installed inside, and the self-locking mechanism 8 includes a fixing seat 801, The large bracket 802, the small bracket 803 and the inner rod 804, the small bracket 803 is fixed on the middle and lower part of the handle rod, a certain distance from the bottom of the inner rod 804, and the large bracket 802 is installed on the second transmission shaft 7 is fixed on the second transmission shaft 7, the small bracket 803 is installed above the big bracket 802, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com