Device for conducting combination and efficient filter pressing in zinc electrolysis process

An electrolytic zinc and process technology, applied in the direction of improving process efficiency, etc., can solve the problems of inability to give full play to the working performance and working efficiency of a filter press, low flow rate of press filtrate, and increased pressure filter resistance, etc., and achieves good dissolution and heating effect. The effect of reducing dosage and low cost

Active Publication Date: 2015-12-16

NINGBO HUALONG ELECTRONICS

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] However, in the filter press operation, the existing centrifugal pumps cannot automatically adapt to such a process to achieve an ideal working state of high efficiency and high quality

Generally, when a centrifugal pump performs filter press operation, the head of the filter press is low in the early stage, but the flow rate is large, so that the motor is in an overload state, and it is easy to burn the motor; The flow rate decreases rapidly. At this time, although the motor works in a light-load and low-power state, the filter press efficiency is very low; although the filter press pump has the maximum head output state, due to the small flow rate of the filter press fluid, the filter press cannot be fully utilized. Work performance and improve work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

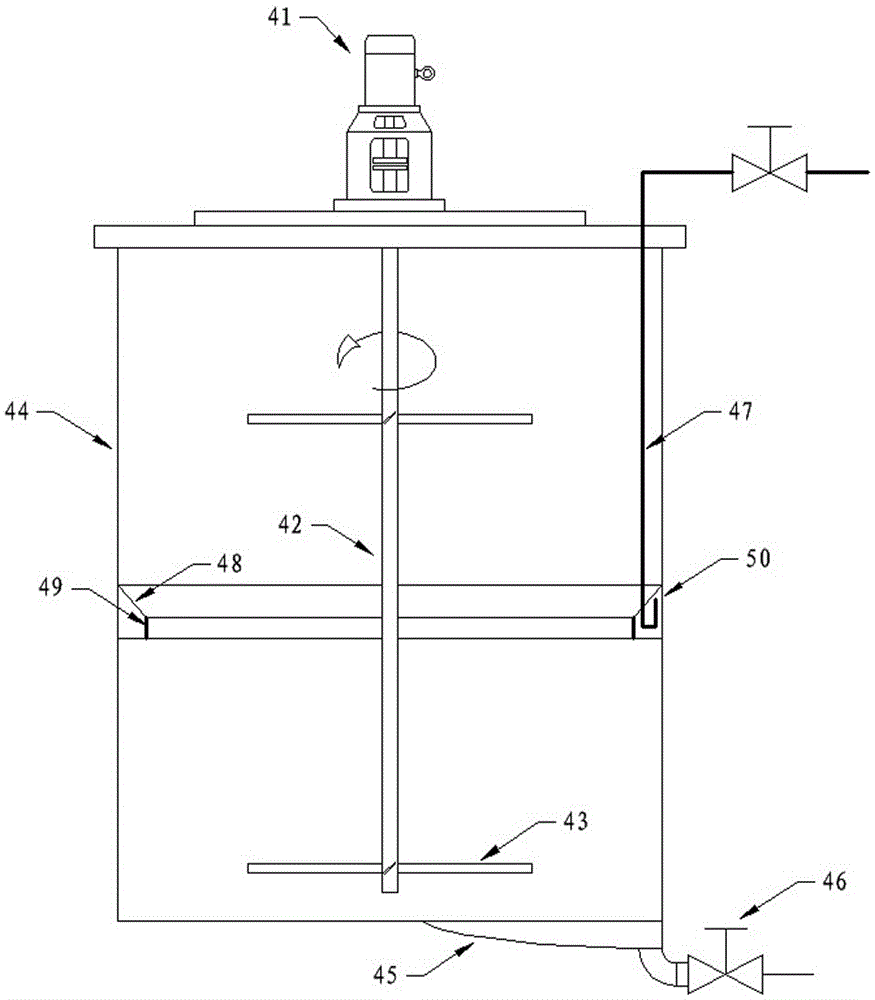

[0020] image 3 It is a schematic diagram of the planar structure of the steam heating compound barrel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

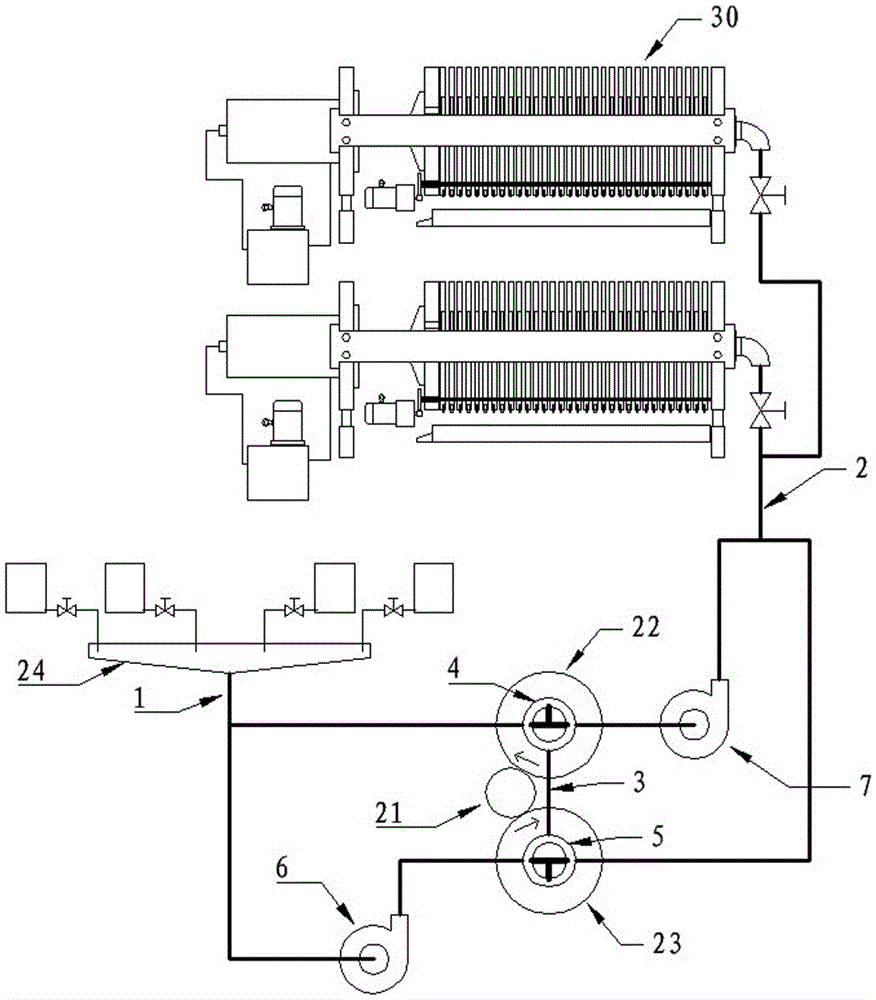

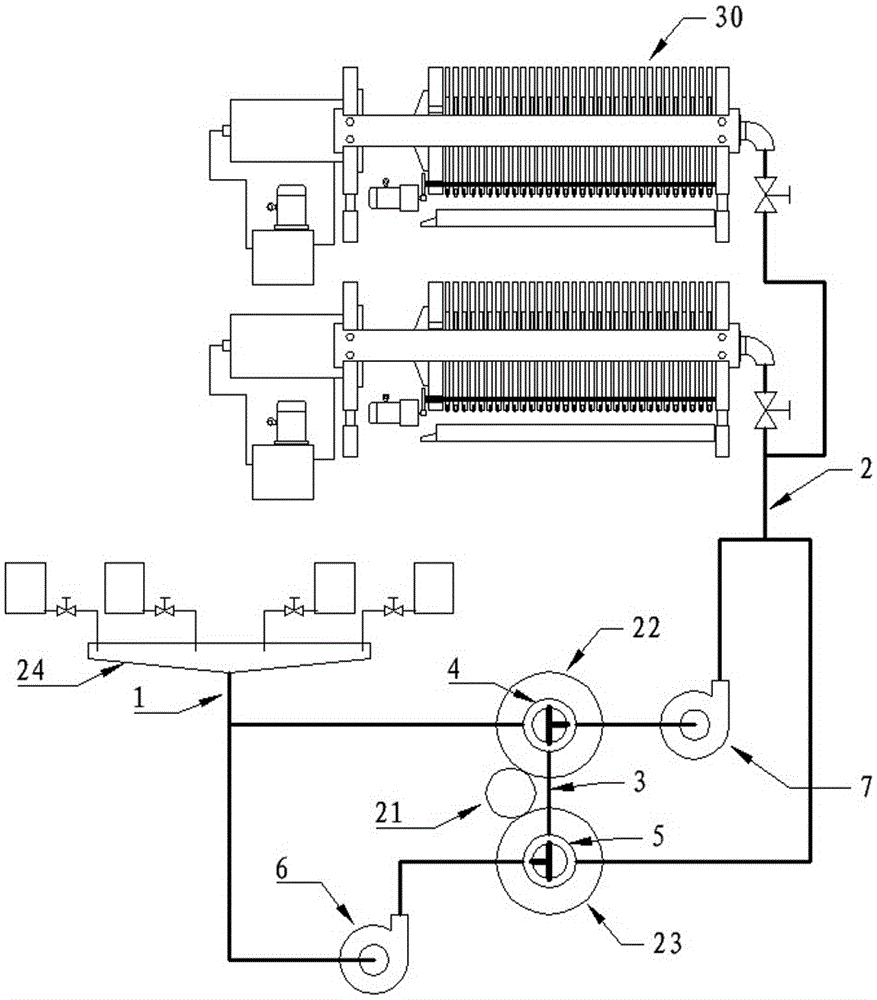

The invention discloses a device for conducting combination and efficient filter pressing in a zinc electrolysis process. The device comprises an inlet pipe, an outlet pipe, two centrifugal pumps and two pressure filters. A first inlet pipe branch is connected with the outlet pipe through a three-way cock and one centrifugal pump. A second inlet pipe branch is connected with the outlet pipe through the other centrifugal pump and the other three-way cock. A driving gear is arranged between gears of the two three-way cocks and drives the two three-way cocks to rotate and switch simultaneously, and the two three-way cocks are communicated with each other up and down through a middle connecting pipe. The inlet pipe is connected with a zinc solution flow trough of an inverted-cone-shaped bottom structure. The two pressure filters are connected in parallel and then connected with the outlet pipe. The flow trough is connected with a steam heating combination barrel. According to the device, the two three-way cocks are used skillfully, so that the convenient and fast switching operation between the series connection and parallel connection of the centrifugal pumps is achieved, and the filter pressing efficiency is improved. The device has the characteristics that the structure is simple, and the operation is not liable to errors. The inverted-cone-shaped bottom of the flow trough benefits the output of a zinc solution and mineral slag. The steam heating combination barrel skillfully uses a steam dissolution ring formed by a taper face ring and a screen aperture cylinder face ring, so that the dissolution warming effect is improved, and noise disturbance does not exist completely.

Description

technical field [0001] The invention relates to a device for compounding and high-efficiency pressure filtration in an electrolytic zinc process. Background technique [0002] Electrolytic zinc is a hydrometallurgical process in which zinc ore is pulverized, compounded, impurity removed, blended and then electrolyzed. Compounding is the process of slurrying zinc ore powder in a compounding tank and adding sulfuric acid for chemical reaction. The combination can obtain soluble zinc sulfate, which is convenient for the later electrolysis operation. [0003] At present, the volume of the compounding barrel for industrial application can reach hundreds of cubic meters. During the compounding process, it is necessary to add steam to the compounding barrel to promote the progress of the compounding reaction, which not only realizes the purification of the electrolyte, but also facilitates the high-efficiency electrolysis in the later stage. [0004] However, steam is added into t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/02C22B3/22C22B3/08

CPCY02P10/20

Inventor 姚茂君银永忠

Owner NINGBO HUALONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com