Built-in driving support mechanism hydraulic dam and its application method

A support mechanism, built-in technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problems of large space occupation, high construction cost, and sedimentation of the driving cylinder, so as to keep the dam surface clean and improve the use of Longevity and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

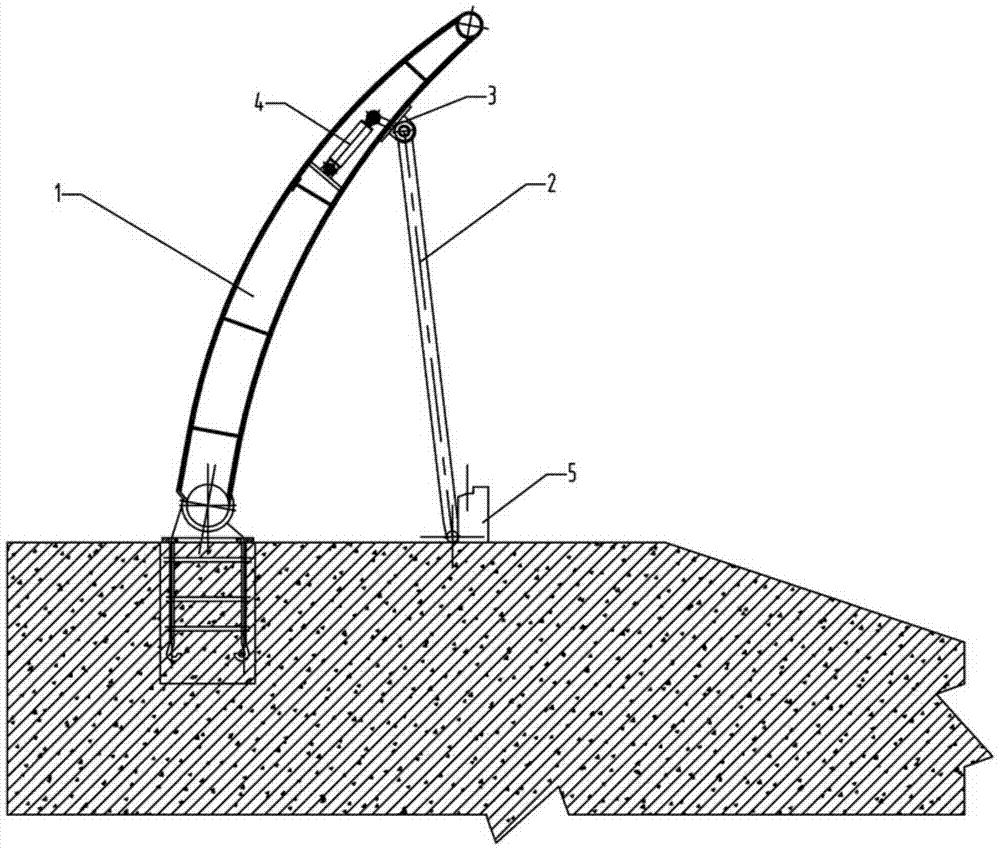

[0051] see Figure 1-3 As shown, the built-in drive support mechanism hydraulic dam has:

[0052] Dam body;

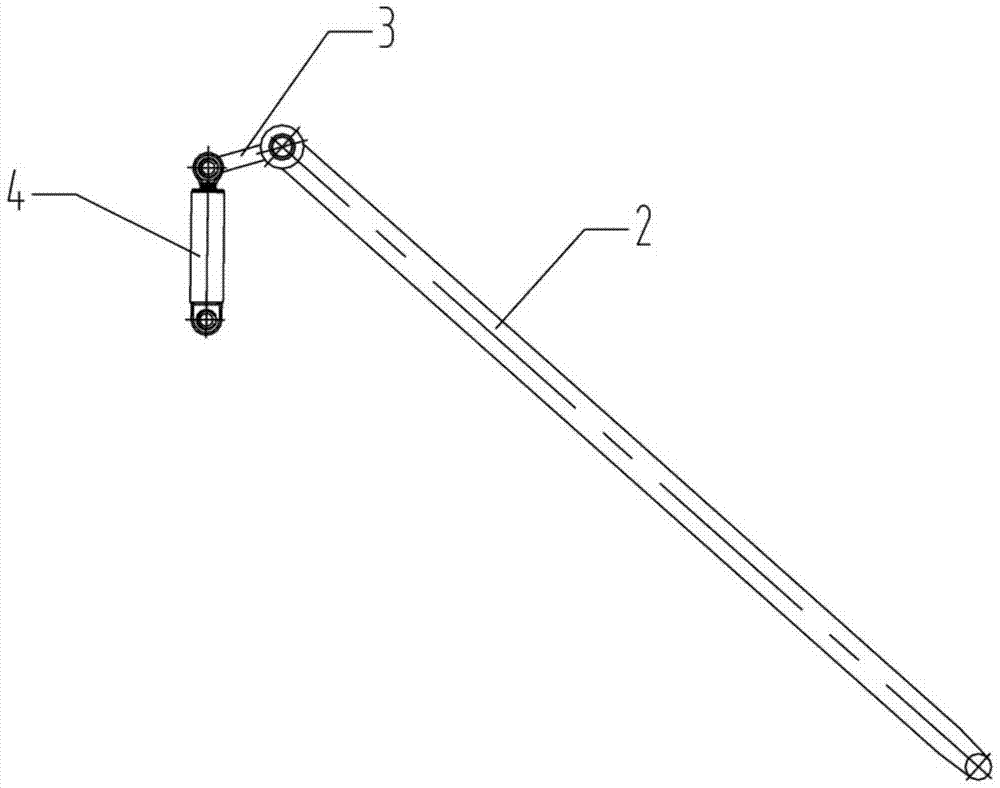

[0053] A telescopic cylinder arranged along the height direction of the dam body and installed on the dam body;

[0054] a link arm, the first end of which is hinged to the piston rod of the telescopic cylinder;

[0055] The support rod used to support the dam body, the upper end of the support rod is fixedly connected with the second end of the link arm.

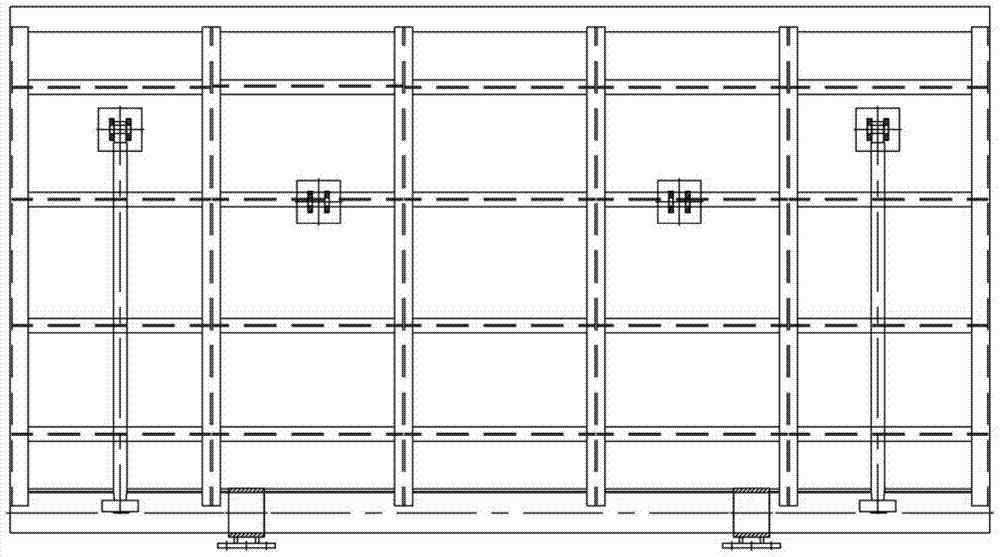

[0056] The telescopic cylinder is installed in the gap between the longitudinal and horizontal beams of the arc cavity in the dam body.

[0057] Two sets of upper hinge supports are fixedly arranged on the dam body, and the upper ends of the support rods are hinged on one set of upper hinge supports. Another group of upper hinge supports is used for installing the main hydraulic cylinder, and the main hydraulic cylinder is used to push the dam body to turn over.

[0058] It also includes a support platform for ...

Embodiment 2

[0088] The above-mentioned method of using the hydraulic dam of the built-in drive support mechanism includes the following steps:

[0089] 1) In the initial state, the dam body is lodging on the support platform; the support rods are received in the dam body;

[0090] 2) When the dam body is lifted, the support rod rises with the dam body;

[0091] 3) When the dam body rises to the specified height, start the telescopic cylinder to make the piston rod contract, the lower end of the support rod opens away from the dam body, falls on the steps of the support platform, and the dam body reaches the first height;

[0092] 4) The piston rod of the telescopic cylinder stretches out, the lower end of the support rod moves towards the direction of the dam body, and falls on the foundation plane of the lower part of the supporting platform, and the dam body reaches the second height;

[0093] 5) When the dam needs to be lowered, start the telescopic cylinder to extend the piston rod, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com