High-temperature-resisting and high-pressure-resisting sealing piston, piston rod combination and thickened oil high-pressure texture analyzer

A high-pressure sealing, high-temperature and high-pressure technology, which is used in the field of high-pressure physical property analysis devices in oil fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

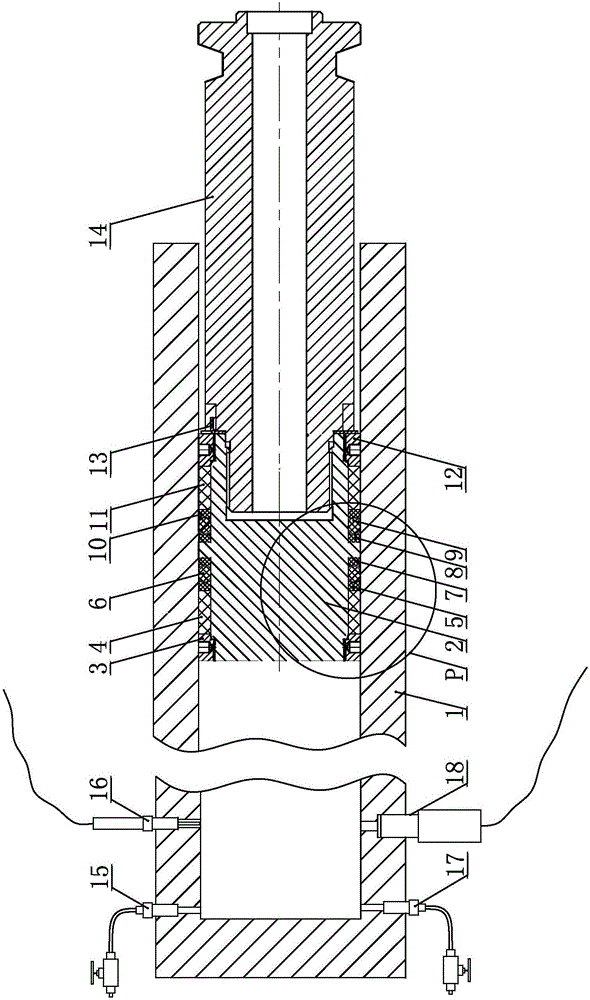

[0026] (1) High temperature and high pressure sealing piston

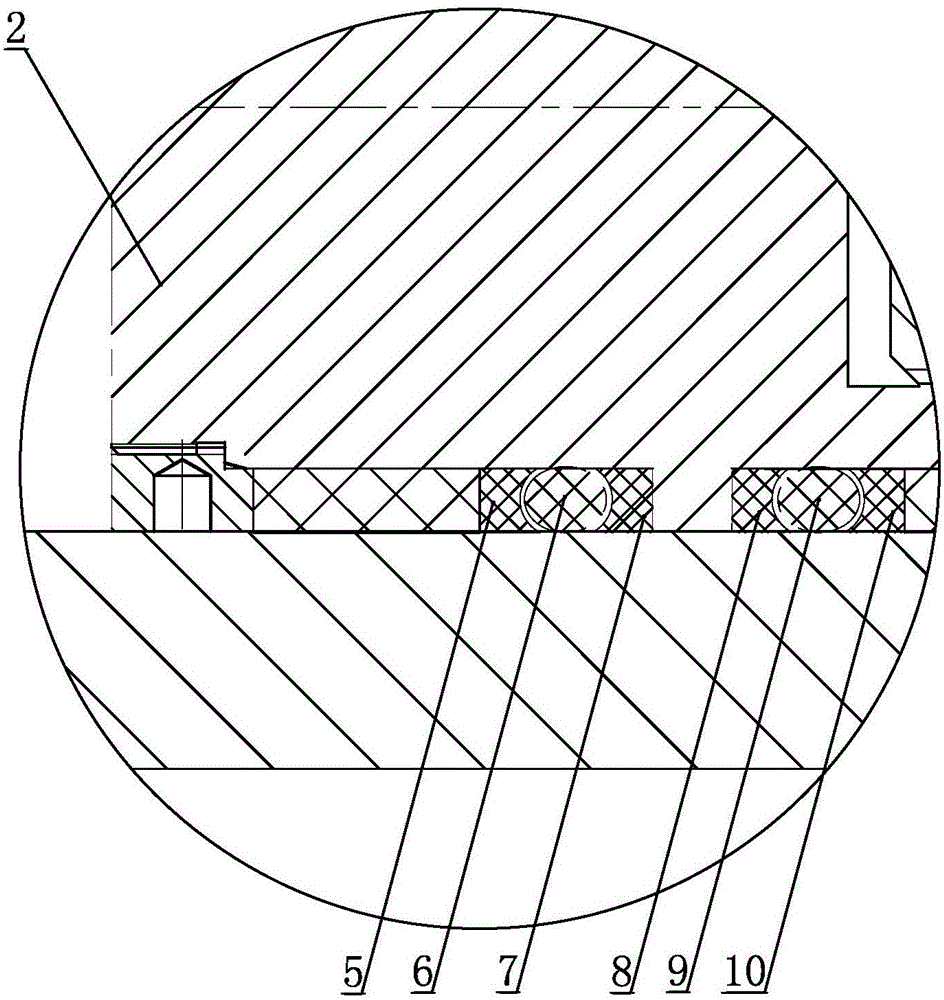

[0027] Such as figure 1 As shown, a high-temperature and high-pressure resistant sealing piston of the present invention includes: a piston body 2; an annular flange is arranged on the outer surface of the piston body 2, wherein the annular flange is perpendicular to the axis of the piston body, and the annular flange is 2 away from the piston body. The distance between the left and right ends is equal.

[0028] On the surface of the piston main body 2, with the annular flange as the center, a high-temperature and high-pressure retaining ring 7 (8), a high-temperature and high-pressure sealing ring 6 (9), a high-temperature and high-pressure retaining ring 7 (8), and a high-temperature and high-pressure retaining ring are arranged symmetrically to the left and right ends of the piston main body 2 respectively. Ring 5(10), guide support ring 4(11) and fastening nut 3(12).

[0029] The guide support rings 4 and 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com