Fireproof internet of things (IOT) field bus cable and manufacturing method thereof

A field bus and bus cable technology, applied in the field of Internet of Things, can solve the problems of accelerating cable burning and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of fireproof type internet of things field bus cable, concrete steps are:

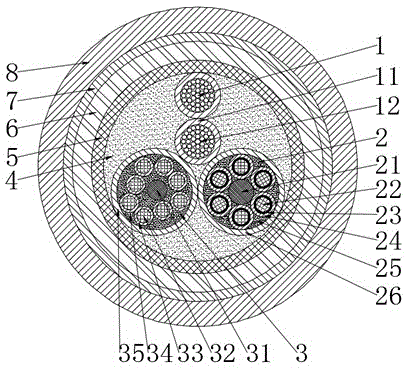

[0039] (1) Production of power transmission cable 1: several conductors are twisted into a first conductive core 11, and then a first silicone rubber composite flame-retardant layer 12 is extruded outside the first conductive core 11 to obtain a power transmission cable 1 ;spare;

[0040] (2) Make optical cable 2: take the first strengthening core 21 as the center, arrange six fiber cores 22 with cladding 23 and coating layer 24 around the first strengthening core 21 to make the first total cable; then use The double-layer co-extrusion process coats the first flame-retardant filling material 25 and the second silicone rubber composite material flame-retardant layer 26 on the outside of the first total cable to obtain the optical cable 2; standby;

[0041] (3) Make data cable 3: Extrude the third silicone rubber composite flame-retardant layer 33 outside the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com