Activated water spray device heated under pressurization

A spray device and technology for activating water, applied in fire rescue and other directions, can solve the problems of water belt and water gun freezing, pipeline can not be too long, eyepiece burst, etc., to avoid pipeline freezing, evaporation and heat absorption, improve The effect of fire fighting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment, the activated water spraying device of heating under pressurization of the present invention will be further described:

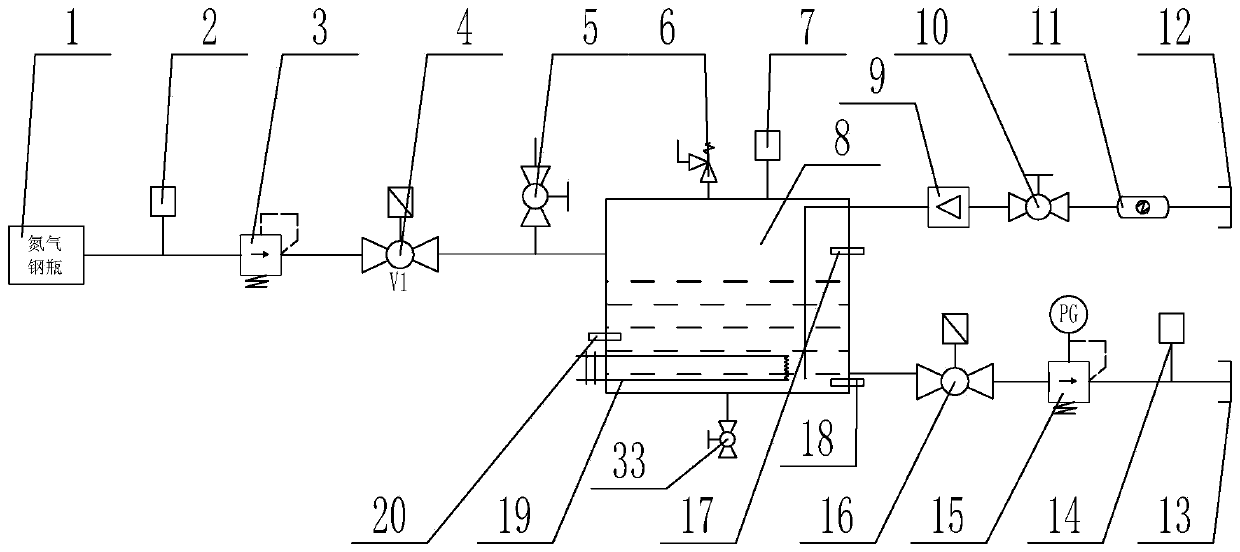

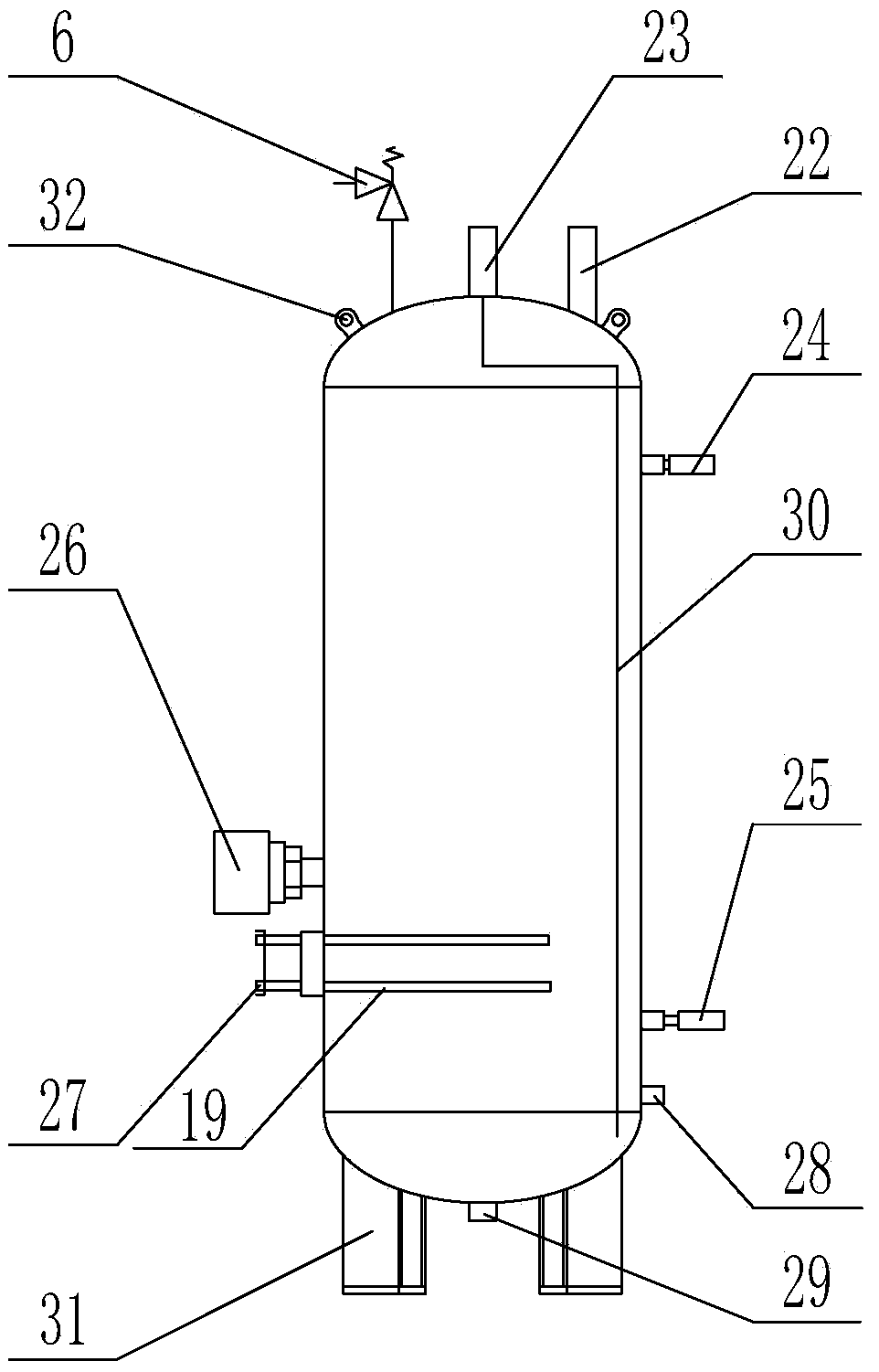

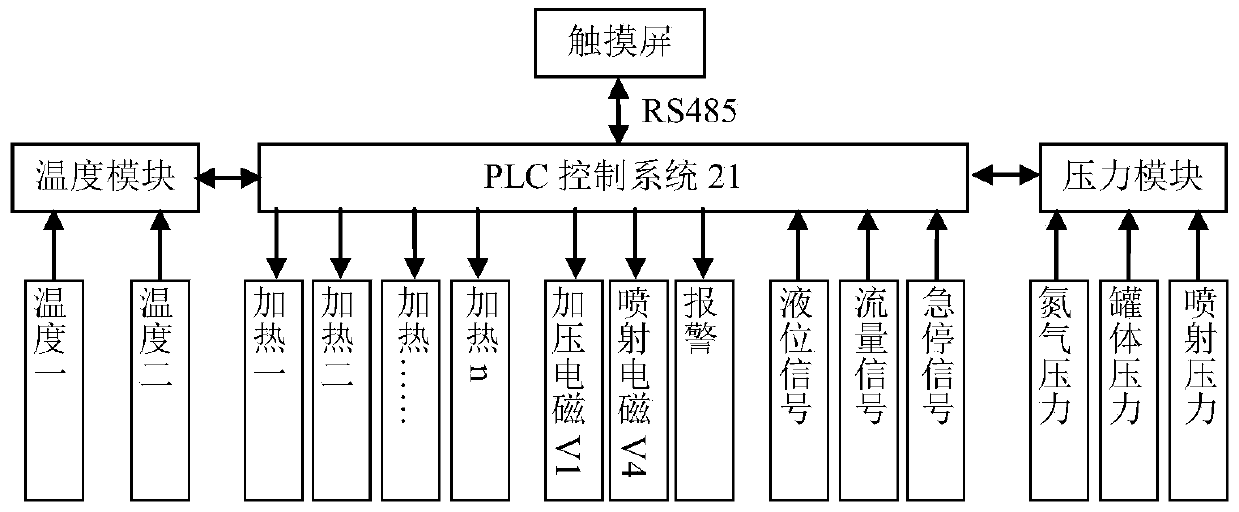

[0021] Such as figure 1As shown, the activated water spraying device heated under pressurization of the present invention includes a water supply pipeline, a pressurization pipeline, a spray pipeline, a PLC control system 21 and is connected with a heating device, a liquid level alarm device, a safety valve 6 and a second The high-pressure and high-temperature tank body 8 of the pressure transmitter 7 . The water adding pipeline includes a flow meter 9 , a manual liquid inlet valve 10 , a filter 11 and a liquid inlet 12 which are sequentially connected through the pipeline, and the flow meter 9 is electrically connected to a PLC control system 21 . The pressurized pipeline includes a nitrogen cylinder 1, a first pressure transmitter 2, a pressure reducing valve 3, a first soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com