Automatic chain grinding machine and chain grinding method

A chain grinding machine and automatic technology, applied in the field of grinding tools, can solve the problems of affecting the cutting effect, unreasonable center of rotation, and existing position changes, etc., and achieve the effect of improving the stability of use, simple and reasonable structure, and simple operation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Describe the embodiment of the present invention in detail below in conjunction with accompanying drawing:

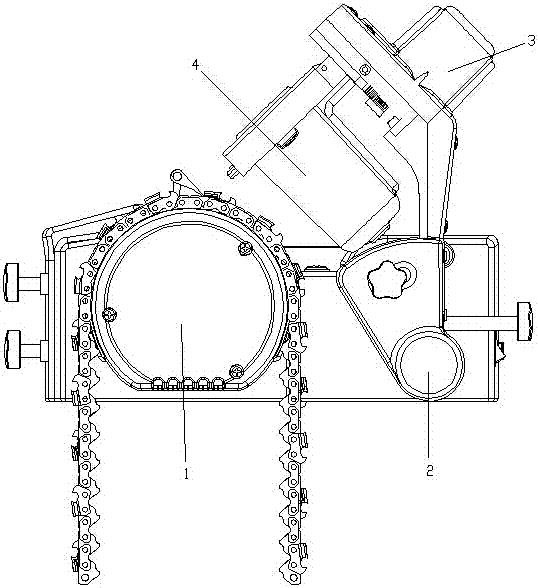

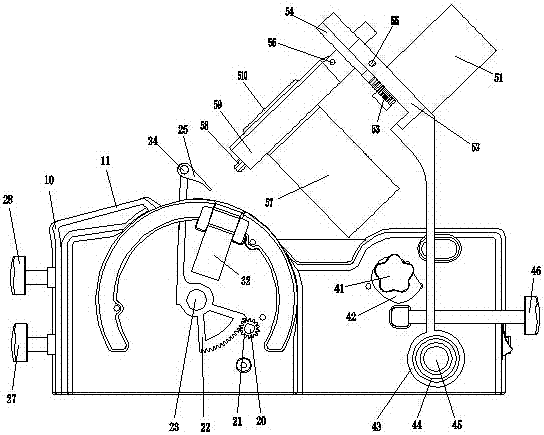

[0042] Such as figure 1 , figure 2 , the embodiment of the present invention includes: box body 10, tooth pushing mechanism (all parts whose codes start with 2), clamping mechanism (all parts whose codes start with 3), grinding indexing mechanism (codes 4 and 5 All parts at the beginning), the electrical control device 11 for controlling the automatic grinding process, and the housing trim 1.

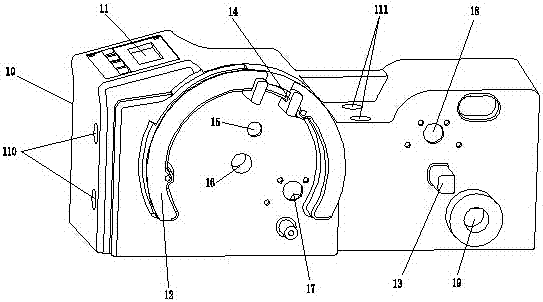

[0043] Such as image 3, there are on the box body 10: the installation hole for installing the display screen 11 of the operation panel; the saw chain installation positioning groove 12 for installing the saw chain; The groove 14 of tight block 33; The clamping motor mounting hole 15 that is used to install clamping motor 30; The tooth pushing mechanism mounting hole 110,16,17 that is used to install pushing tooth mechanism; Mounting holes 18, 19 for the grinding ind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap