U-shaped tube grasping unit of a long U-shaped tube automatic intubation system with fin assembly

A technology of grasping unit and U-shaped tube, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low intubation efficiency, high labor intensity of operators, and unguaranteed production capacity, etc., to achieve guaranteed work Non-interference with each other, high degree of equipment automation, avoiding the effect of stopping work and waiting for materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

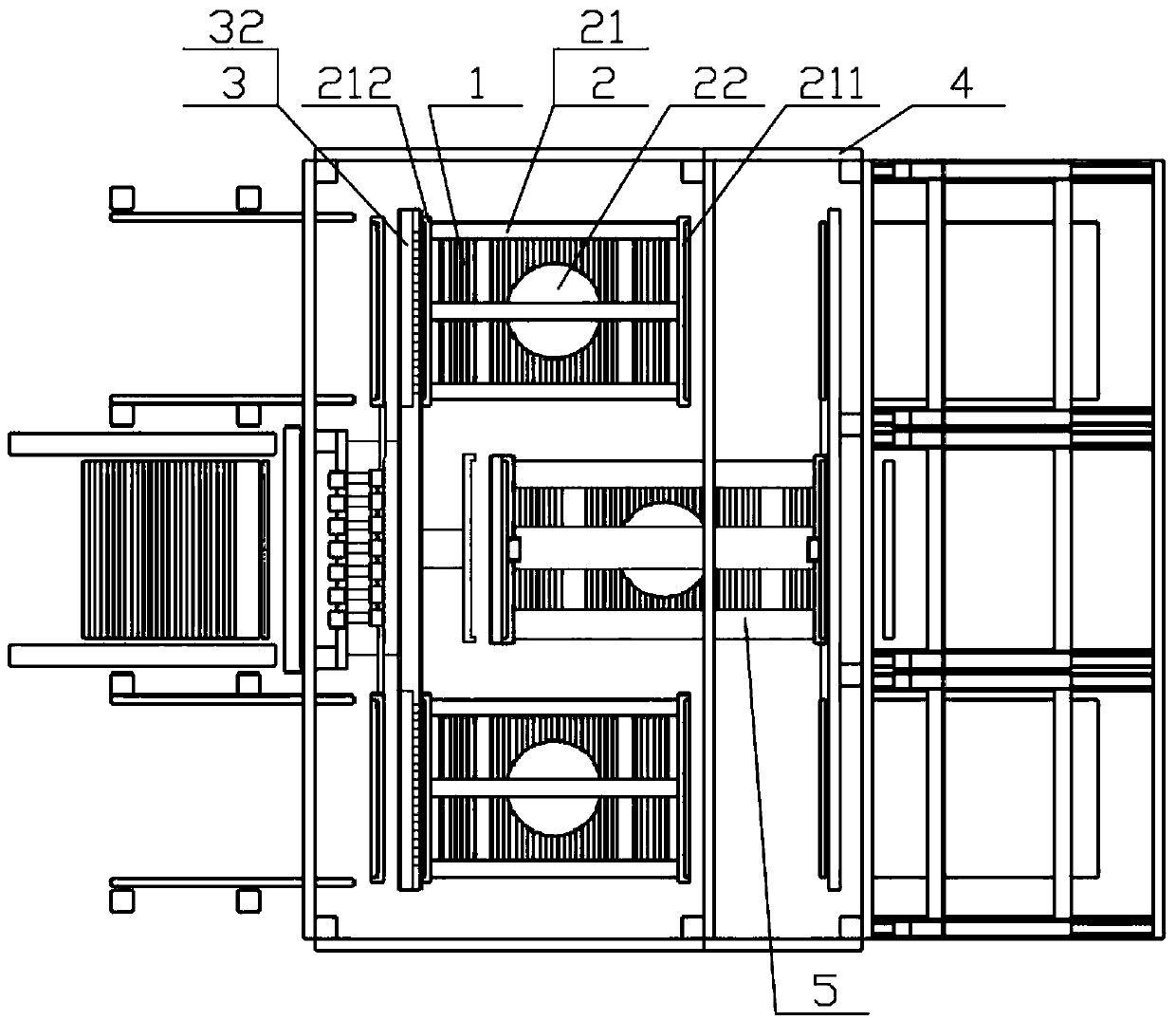

[0031] The present invention will be further described below in conjunction with the accompanying drawings (the following description takes the direction where the fin assembly accompanying tooling indexing unit 5 is located in the U-shaped tube grabbing unit of the long U-shaped tube automatic intubation system of the fin assembly as the front ).

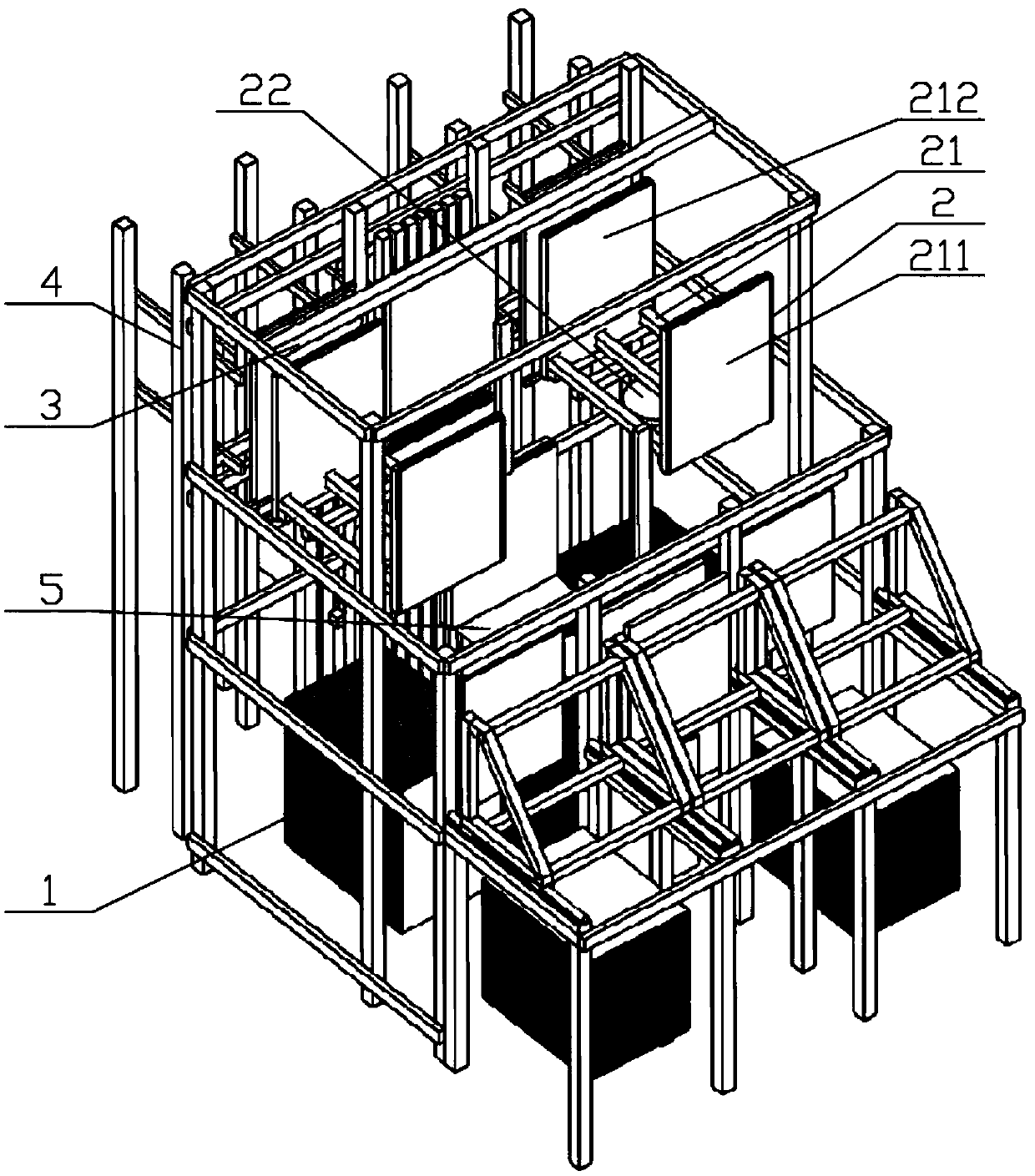

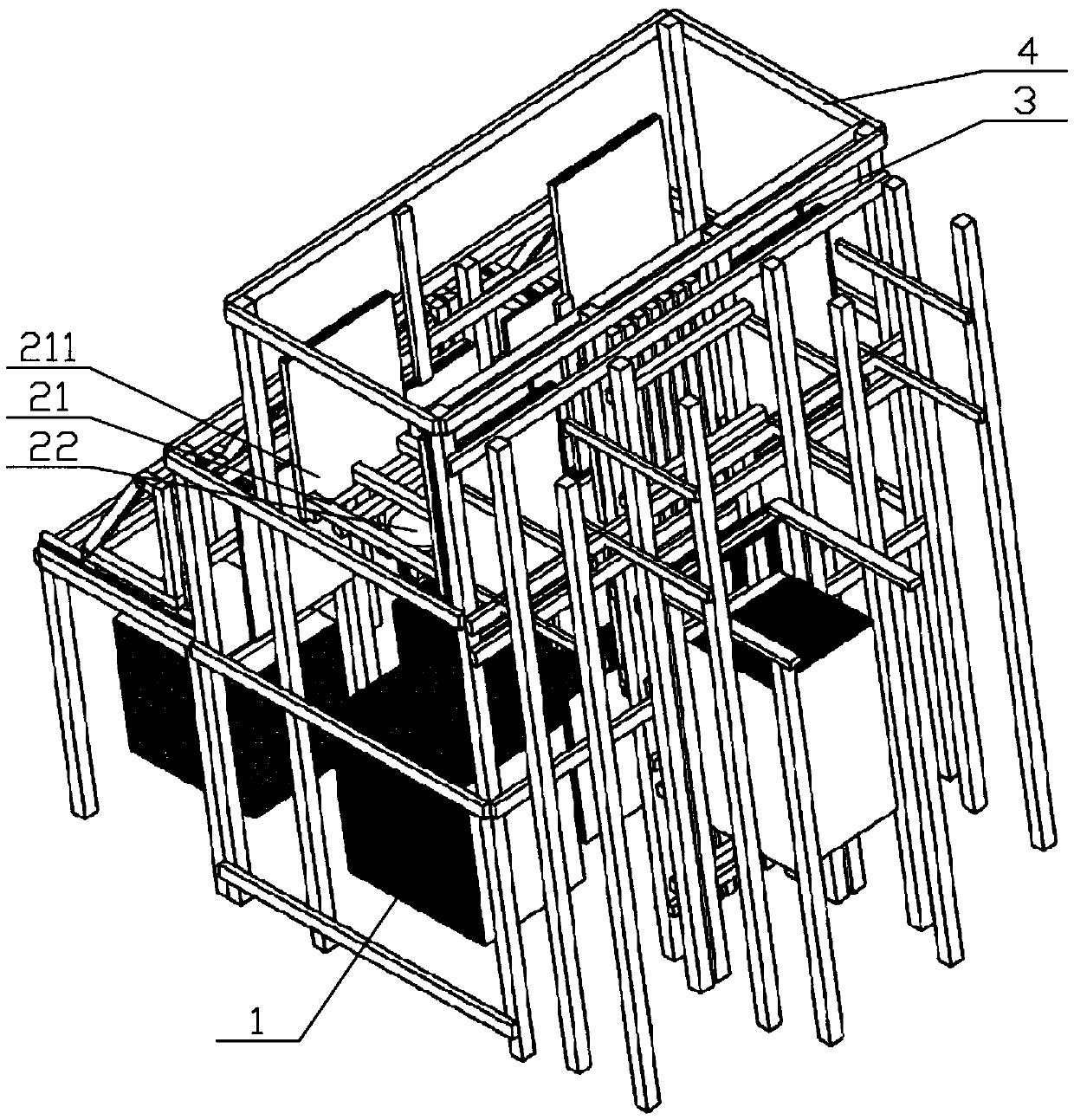

[0032] Such as Figure 1 to Figure 4As shown, the U-shaped tube grabbing unit of the fin assembly long U-shaped tube automatic intubation system is arranged at the middle rear of the support frame 4, including the U-shaped tube bracket 1, the U-shaped tube accompanying tooling indexing working part 2 and U-shaped tube grabbing device3.

[0033] The U-shaped tube bracket 1 is set in two pieces, which are respectively arranged on the lower layer of the supporting frame 4, on both sides of the fin assembly accompanying tooling indexing unit 5, and directly below the U-shaped tube accompanying tooling indexing working part 2 , includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com