Numerical-control screw rod polishing machine tool

A screw and machine tool technology, applied in the field of CNC screw polishing machine tools, can solve the problems of unsatisfactory polishing, hidden safety hazards, and high repair rate, and achieve good economic benefits, prevent occupational diseases, and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

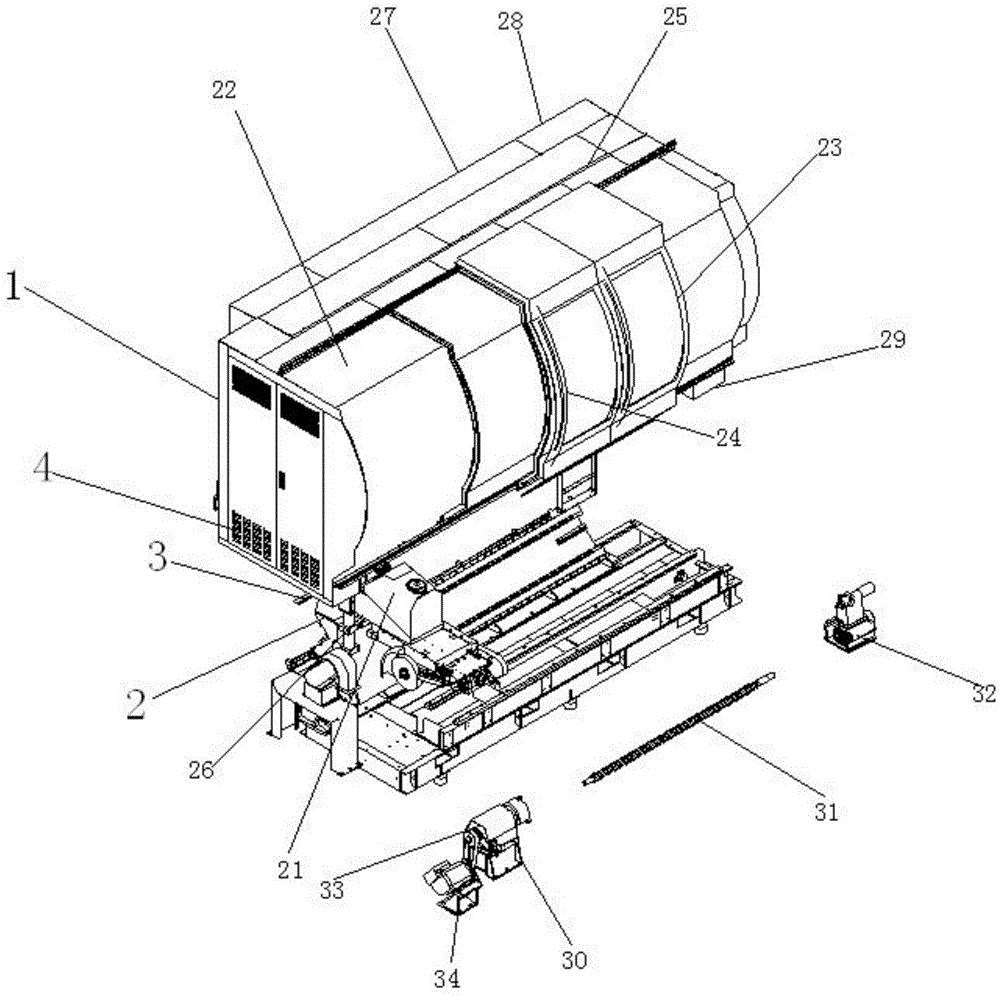

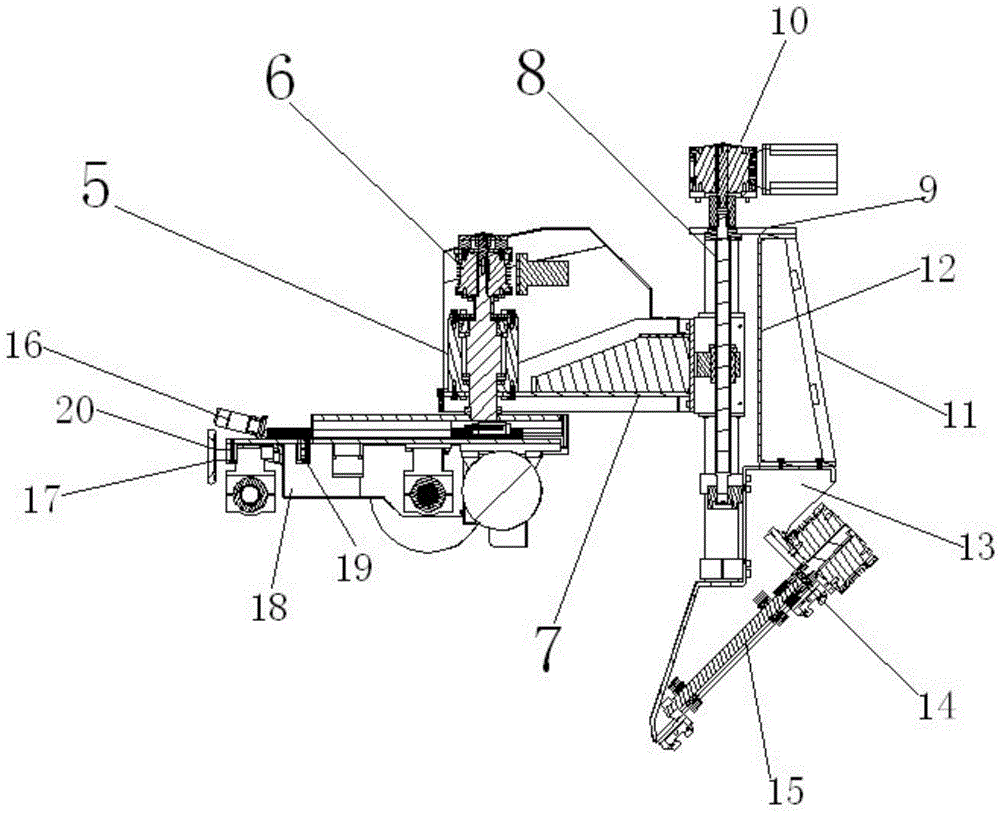

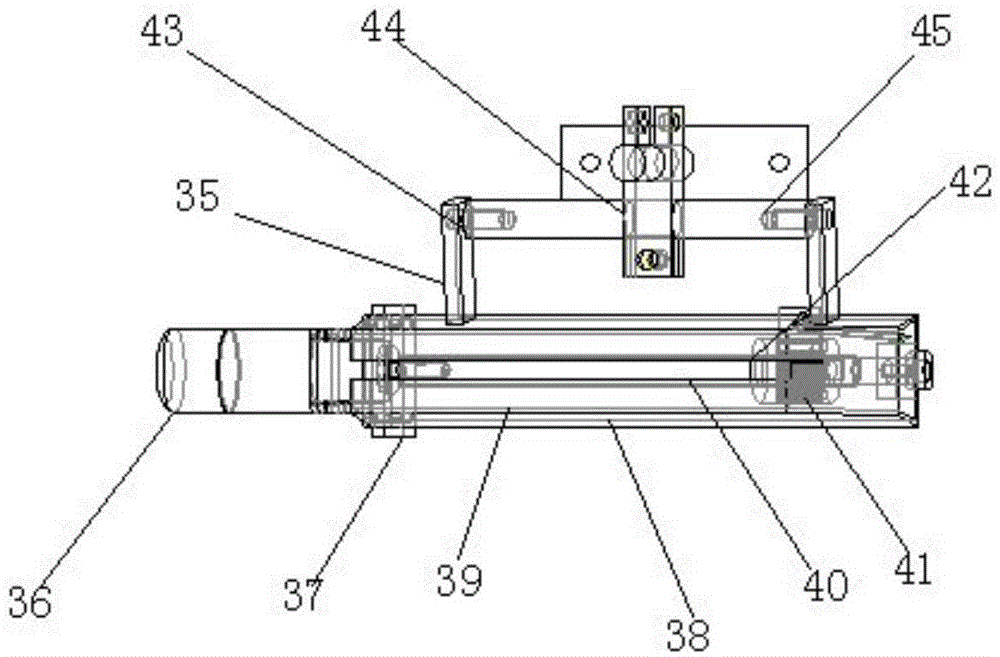

[0015] Such as Figure 1 to Figure 3 As shown, the CNC screw polishing machine tool includes a fuselage shell 1 and a base 2, and the base 2 is fixed with a working platform 3 and a pillar 4, and a driving mechanism 5 is installed on the working platform 3, and the driving mechanism 5 The end is slidingly connected with the guide rail on the working platform 3 up and down, and the bottom of the working platform 3 is slidingly connected with the base 2 through the dovetail guide rail. , the lift head 7 is connected with the ball screw 8 through the outer hexagonal flange screw, the top of the ball screw 8 is equipped with a gland 9, the gland 9 is fixed with a lifting drive device 10, and the lower end of the gland 9 also has a support 11 , the support 11 is provided with a column 12 parallel to the ball screw 8, and the lower end of the support 11 and the ball screw 8 is equipped with a drive head 13 through a hex flange screw and a support frame, and the drive head 13 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com