Method, device and system for manufacturing rehabilitation insole

A production method and technology of insole, applied in the direction of additive processing, etc., can solve the problems of very changeable contact, insole can not be applied well, no optimized design and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

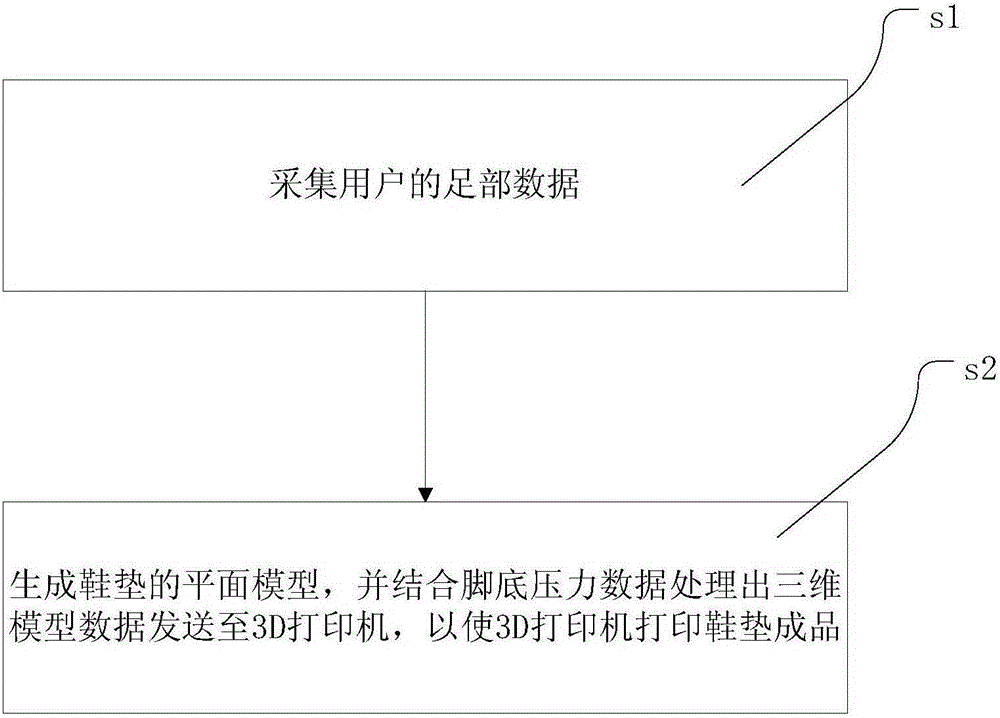

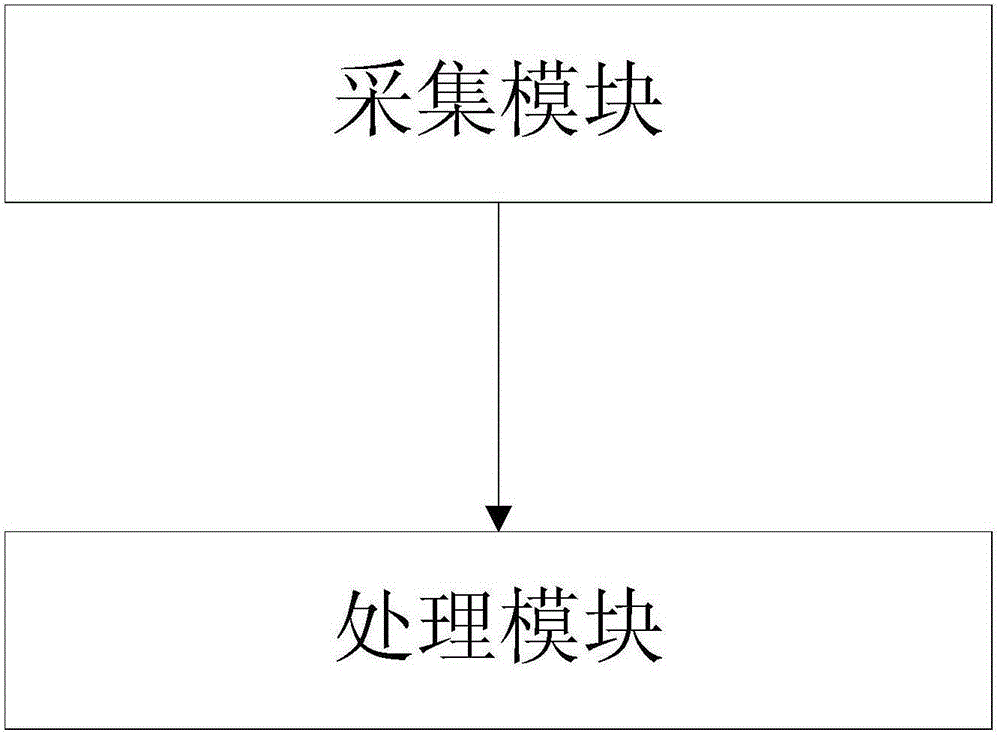

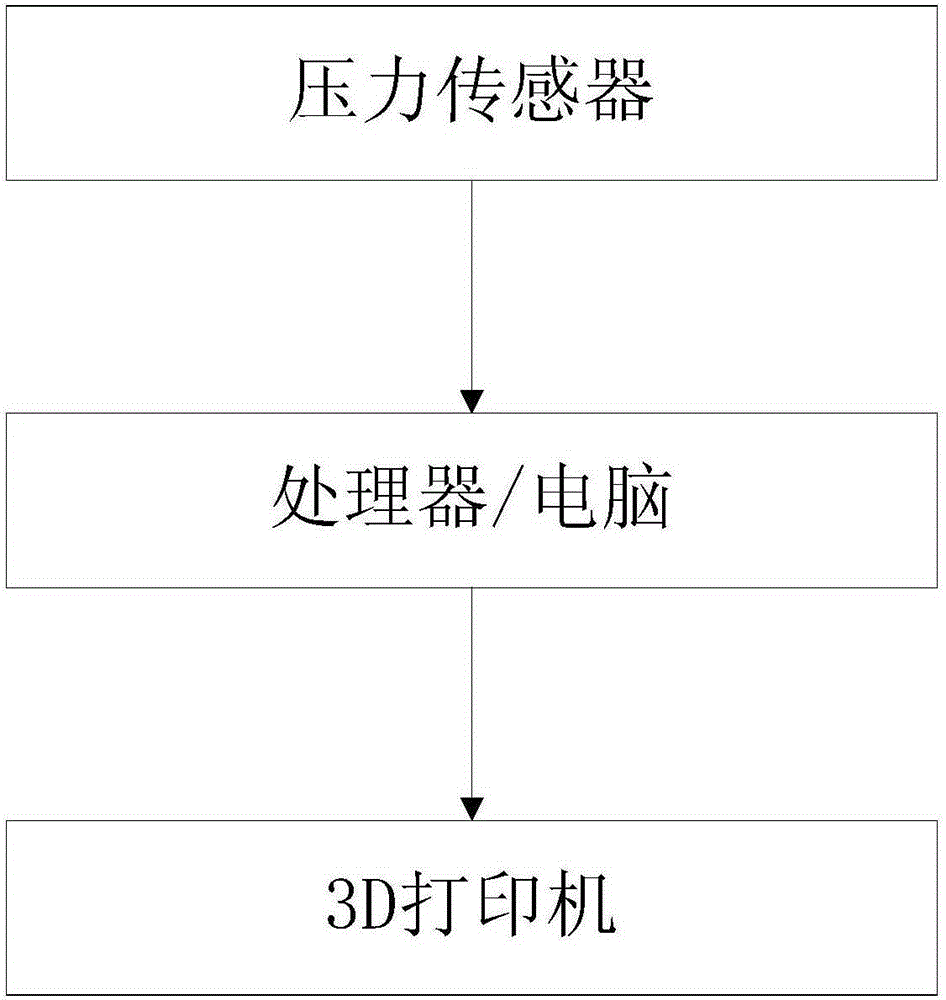

Method used

Image

Examples

Embodiment 1

[0065] Step s24 in this embodiment specifically includes the following sub-steps:

[0066] Step s241: define the ratio between D1 and D2 as X, that is, D1 / D2=X, and determine the scope of X;

[0067] The present invention collects data through a pressure sensor. For the foot, there is an arch, which is composed of arched joints of tarsal bones and metatarsal bones, and tissues with elasticity and contraction force such as ligaments and tendons on the soles of the feet. A protruding upward arch, which can be divided into longitudinal arch and transverse arch. The main function of the arch of the foot is to disperse the gravity from the ankle joint through the talus forward to the head of the metatarsal bone, and transmit it backward to the calcaneus to ensure that the sole of the foot can stand upright. The stability of the support. The arch of the foot usually protrudes upwards, so when the user walks or stands on the pressure plate, the arch of the foot cannot touch the pres...

Embodiment 2

[0076] This embodiment is an instruction for making insoles for users with flat feet. One of the differences between this embodiment and Embodiment 1 is that step s242 is: see Figure 6 , when X≤0.5, the angle between the plane where the inner area of the plane model is located and the horizontal plane is set to 2 degrees, and the direction of the included angle is inward, so that the outer edge of the inner area is higher than the inner part, and the foot can be controlled When the foot is everted when walking, the grid density of the inner area is set to 1 to 3 times that of other areas, and the thickness of the area where the plane model corresponds to the arch position is adjusted to half of the preset thickness; The inner side of the plane model is the width between the outer side of the thumb area and the inner edge, and the length is between the forefoot and the rear heel, which is Figure 6 B area in;

[0077] Patients with severe flat feet do not have the normal ho...

Embodiment 3

[0080] This embodiment describes how to make insoles for users with normal feet but with collapsed transverse arches, and aims to introduce how to combine the plane model with plantar pressure data to obtain the final 3D insole data. In this embodiment, X=2, which belongs to the range of normal feet, and the thickness of the arch of the foot is the preset thickness, that is, the preset thickness mentioned in the present invention, which is based on the normal feet, and the thickness of other patients Then add the preset thickness to make relevant adjustments, the mesh density of the arch of the foot can be consistent with other parts, see Figure 7 , the processor can analyze according to the sole pressure data (the processor can also have a display, according to the sole pressure data can be displayed in the plane model, marked with different colors, different colors represent different force ranges) the soles of the feet Excessive pressure in the C area of the forefoot mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com