A kind of automobile engine suspension assembly

A technology of automobile engine and assembly, applied in the direction of power plant, vehicle parts, jet propulsion device, etc., can solve the problems of poor fatigue resistance, vibration isolation, poor decoupling performance, etc., achieve good fatigue resistance and ensure vibration isolation Good performance and vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

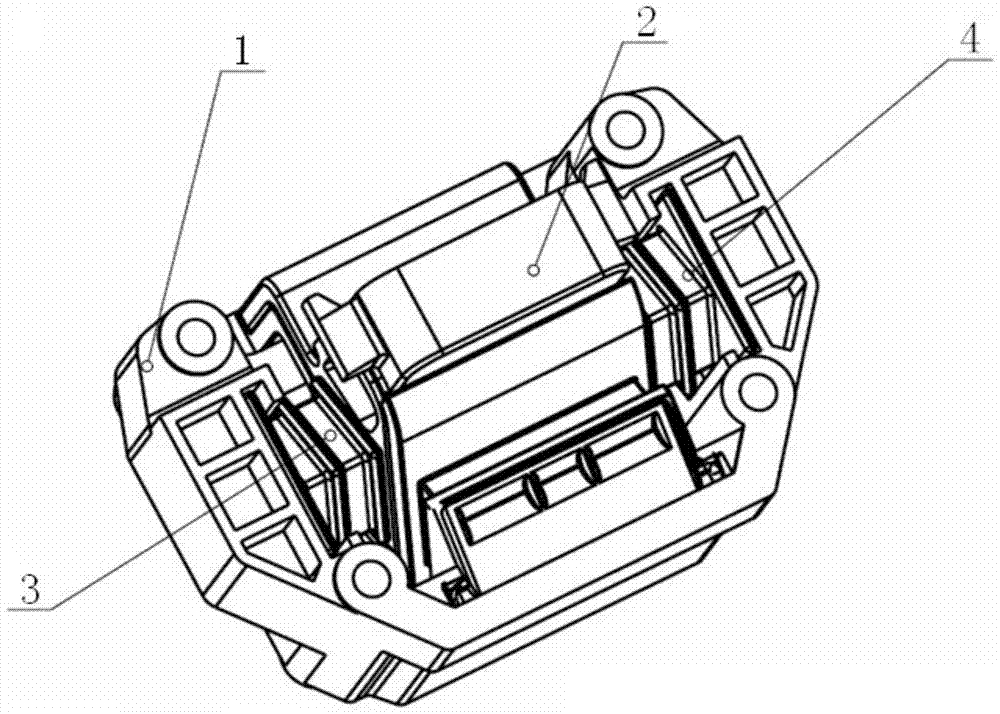

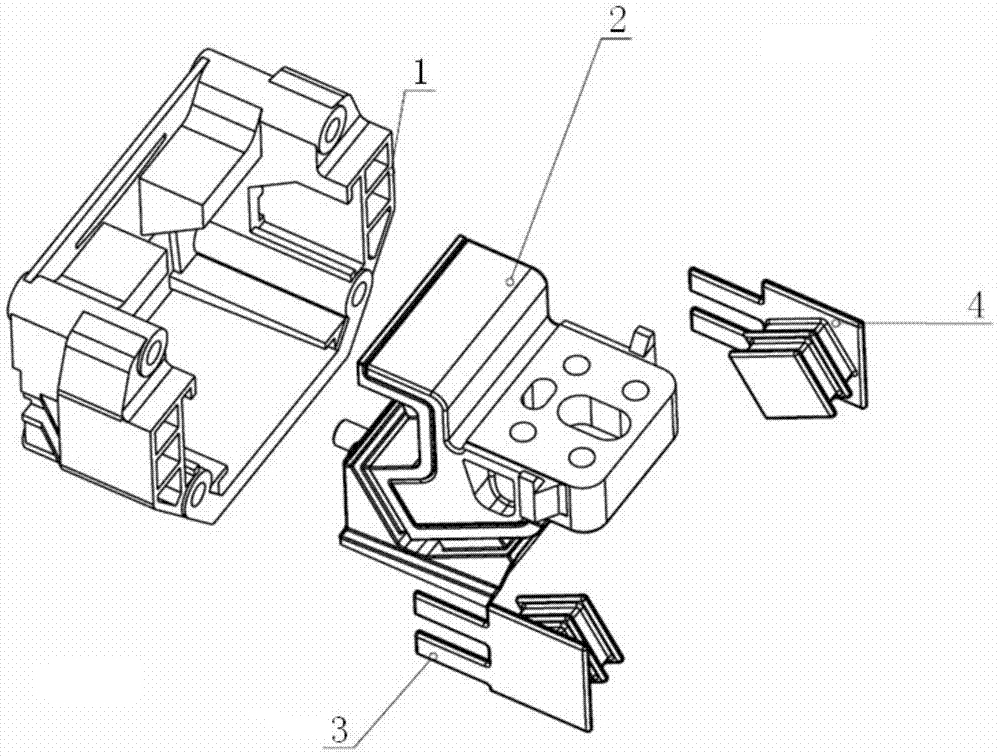

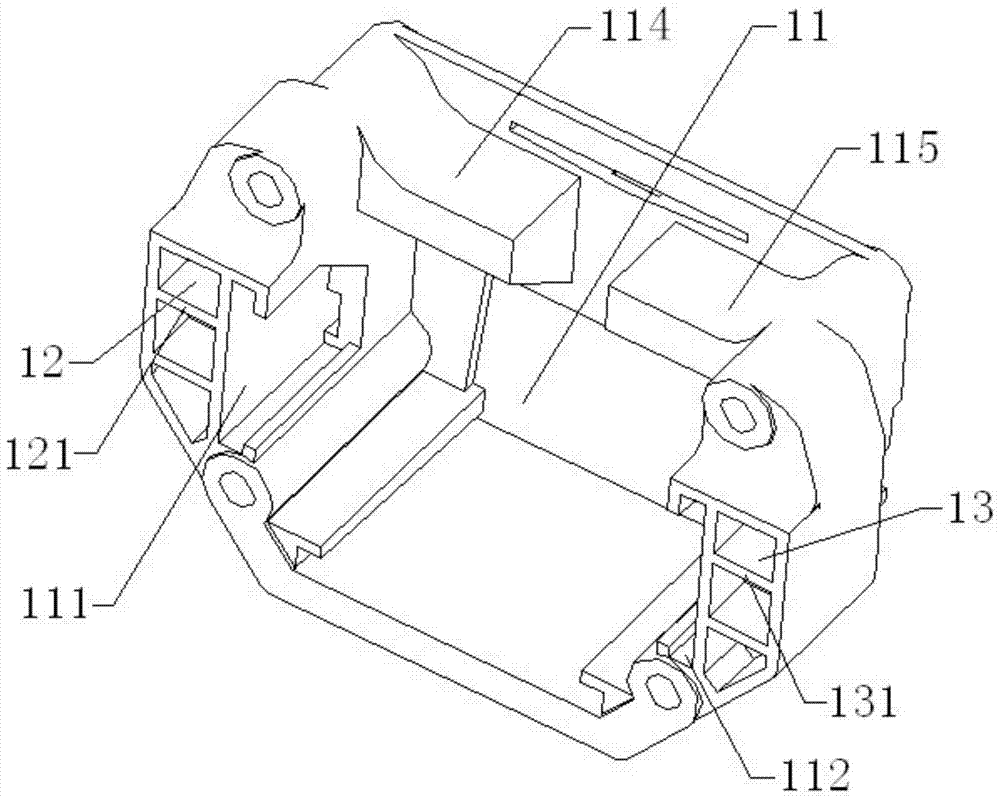

[0059] see Figure 1 to Figure 12 , an automobile engine suspension assembly, comprising an outer frame 1 and an inner frame assembly 2, the outer frame 1 is provided with an inner cavity 11 to cooperate with the inner frame assembly 2, and the left side of the inner cavity 11 is provided with a Rectangular slot 111 is used to cooperate with No. 1 rubber unit 3. No. 1 rubber unit 3 includes No. 1 metal limiting plate 31 which is parallel to and connected with No. 1 rectangular slot 111. The middle part is provided with No. 1 metal middle The No. 1 square rubber unit 32 of the plate 322, the number of the No. 1 metal intermediate plate 322 is one piece, the right side of the inner cavity 11 is provided with a No. 2 rectangular groove 112 to match the No. 2 rubber unit 4, The No. 2 rubber unit 4 includes the No. 2 metal limiting plate 41, the No. 2 square rubber unit 42 with the No. 2 metal intermediate plate 422 in the middle, which is parallel to each other and connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com