Mobile catenary of electrified railway coal loading station

A technology of electrified railway and catenary, which is applied in the direction of power lines, transportation and packaging, overhead lines, etc., can solve the problems of restricting the efficiency of logistics chain, space occupation, and the inability to erect flexible catenary, and achieve infinitely adjustable size and beautiful structure , the effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

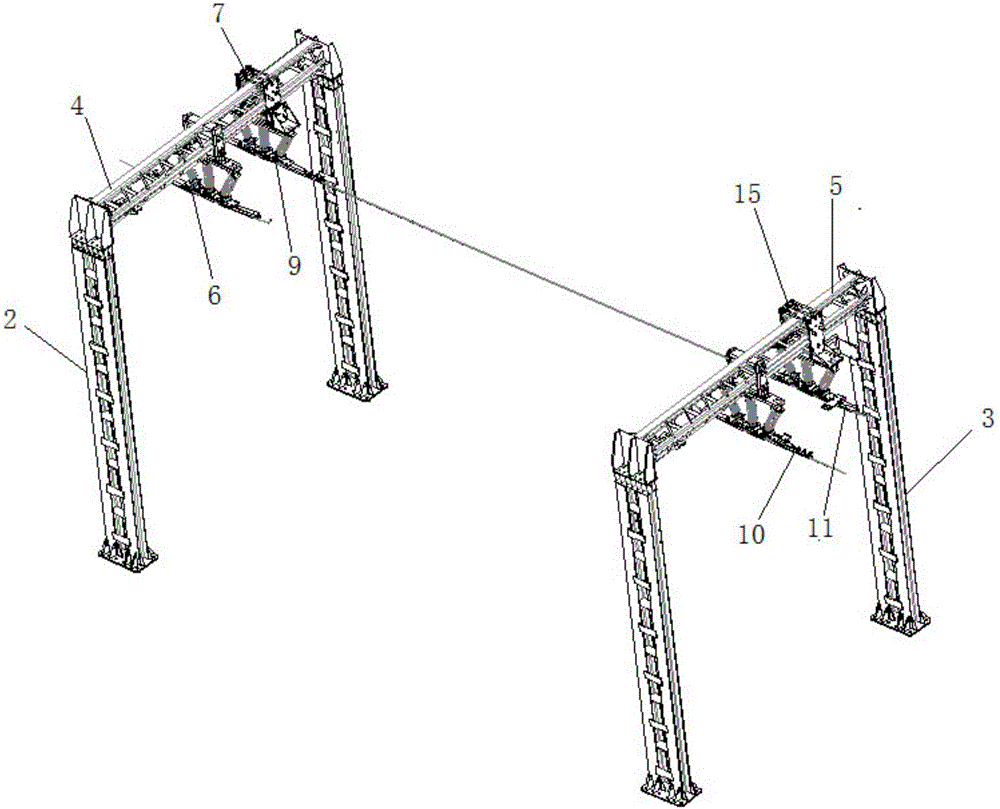

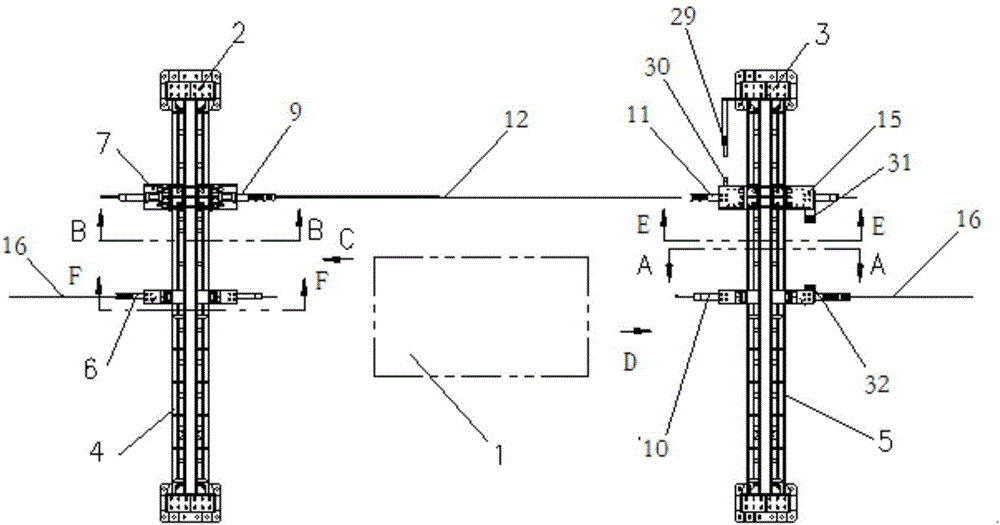

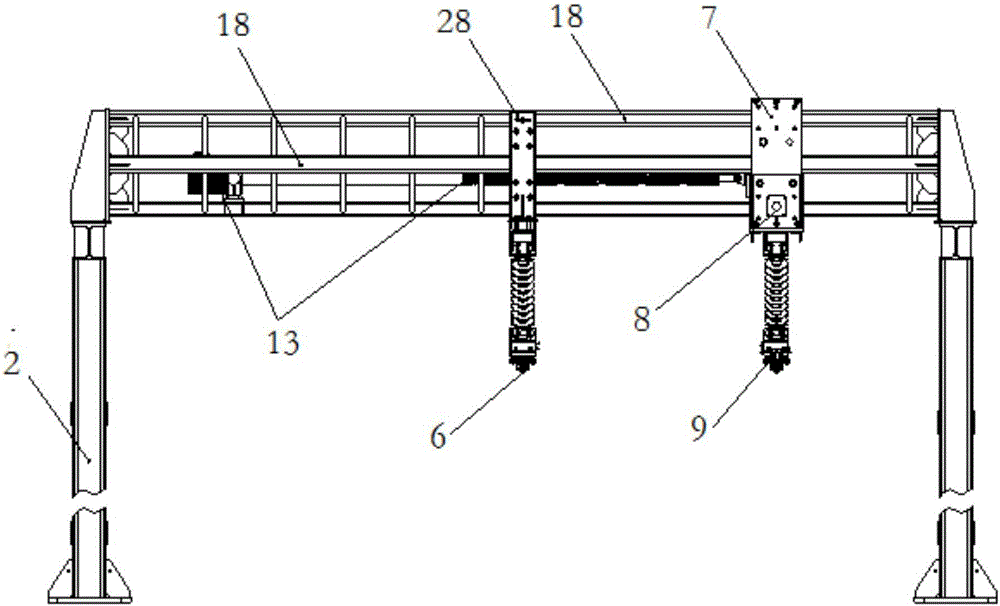

[0022] Attached Figure 1-7 Specific embodiments of the present invention are described in detail.

[0023] An electrified railway coal loading station mobile catenary, comprising a left portal frame 2 and a right portal frame 3 located on both sides of the hopper warehouse 1, and the left portal frame 2 and the right portal frame 3 span across the hopper warehouse 1. On the side of the line, the left cross beam 4 at the top of the left portal frame 2 and the right cross beam 5 at the top of the right portal frame 3 are rigidly hung with a symmetrical left fixed bus bar 6 and a right fixed bus bar through insulators 17 below the middle. 10; The left beam 4 is equipped with a left mobile trolley 7 that can move back and forth, and the left mobile trolley 7 is located between the left fixed busbar 6 and the rear column of the left portal frame 2; the left mobile trolley 7 is equipped with a smooth The tension compensation trolley 8 moving in the direction of the line is rigidly su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com