Wiring groove for rail vehicle

A technology for rail vehicles and wiring troughs, applied in the direction of vehicle components, electrical components, circuits or fluid pipelines, etc., can solve the problems of time-consuming and laborious installation of structural parts, disordered wiring, and increase the workload of installing wiring troughs. Efficiency and accuracy, anti-electromagnetic interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

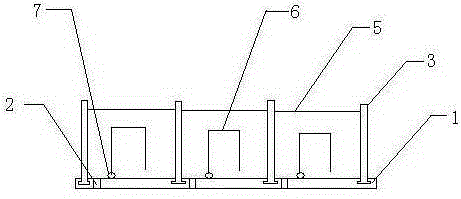

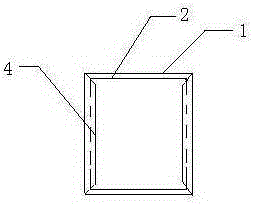

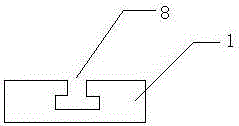

[0015] like figure 1 , figure 2 As shown, a wiring trough for a rail vehicle includes a bottom plate 1, and a plurality of ventilation holes 2 are provided on the bottom plate 1 to dissipate the heat generated when the line is in operation. The base plate 1 is plugged with several isolation plates 3, which can play the role of releasing electromagnetic interference. The two vertical planes opposite to the isolation plate 3 are respectively provided with plate grooves 4, and the spacers on each isolation plate The number of plate slots is 4, and a cover plate 5 is provided between the two isolation plates. The shape of the cover plate 5 can be "П" or "∩" shape, and it is plugged into the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com