Steel wall crawler with multi-directional floating left and right discs

A crawler, multi-directional technology, used in the non-destructive testing of large steel parts and the field of steel wall crawler, can solve the problems of the crawler car losing driving force, falling, and not being able to float in multiple directions, so as to improve the ability of crawling through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

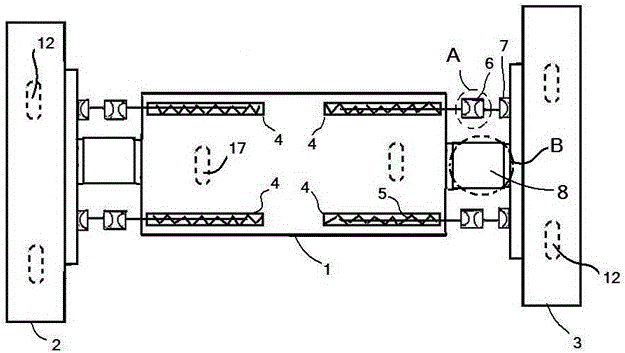

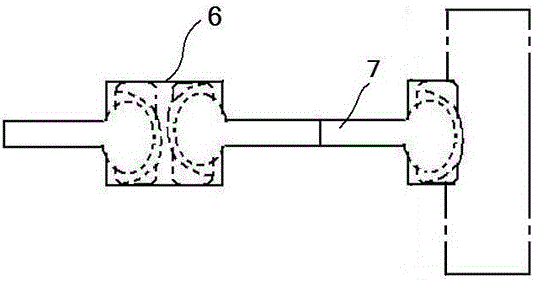

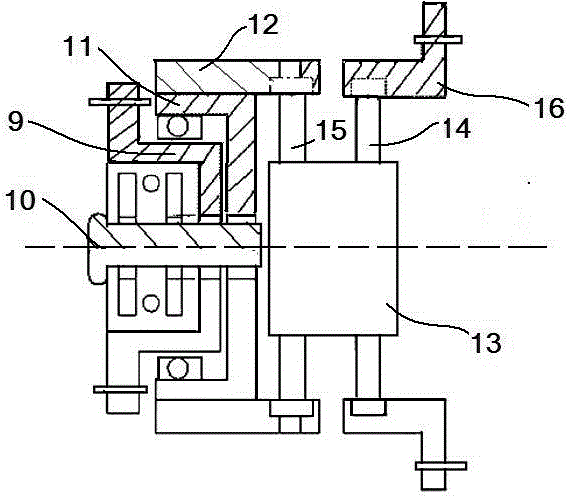

[0015] Example 1: see Figure 1~3 . The chassis of the crawler includes a central plate 1 and left plates 2 and right plates 3 symmetrically distributed on both sides of the central plate 1 . The left disc 2 and the right disc 3 are respectively fastened with four gas springs 4, so 8 gas springs 4 are housed on the crawler. figure 1 Only four of the middle gas springs 4 can be seen, because the other two gas springs on the left disc 2 and the right disc 3 are in the respective positions. figure 1 Directly below the two gas springs that can be seen in the figure, it is just blocked by the two gas springs that can be seen in the top view. The structure of gas spring 4 is to install a helical spring 5 additional in the cylinder of commercially available gas spring. One end of each gas spring 4 is connected with one end of a rod end joint bearing assembly 6, and the other end of the rod end joint bearing assembly 6 is docked with a rod of a commercially available rod end joint ...

Embodiment 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the structure of the self-adaptive coupling assembly is shown in Figure 4 Shown: the left disc and the right disc are respectively connected with the middle disc 1 through the self-adaptive coupling assembly. The spherical club head bowl seat 21 is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com