A natural gas pipeline robot support and mileage measuring device

A natural gas pipeline and measurement device technology, applied in the field of natural gas pipeline robot support and mileage measurement device, can solve problems such as unstable operation, pipeline coating wear, cup wear, etc., to achieve accurate detection signals, good support, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

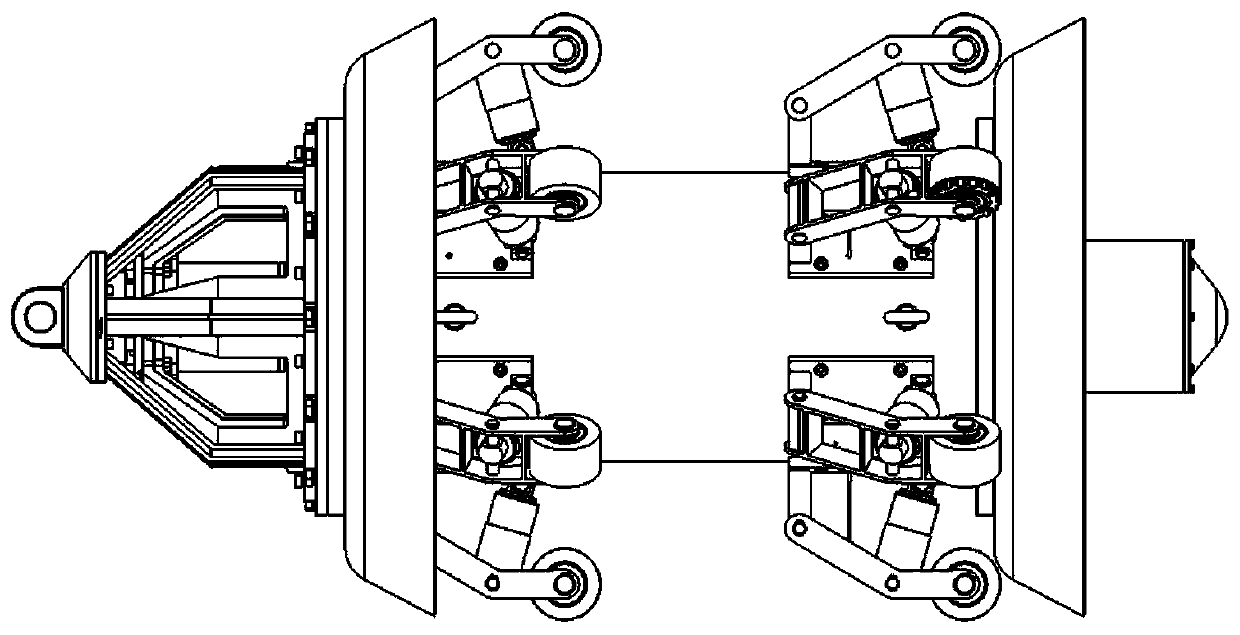

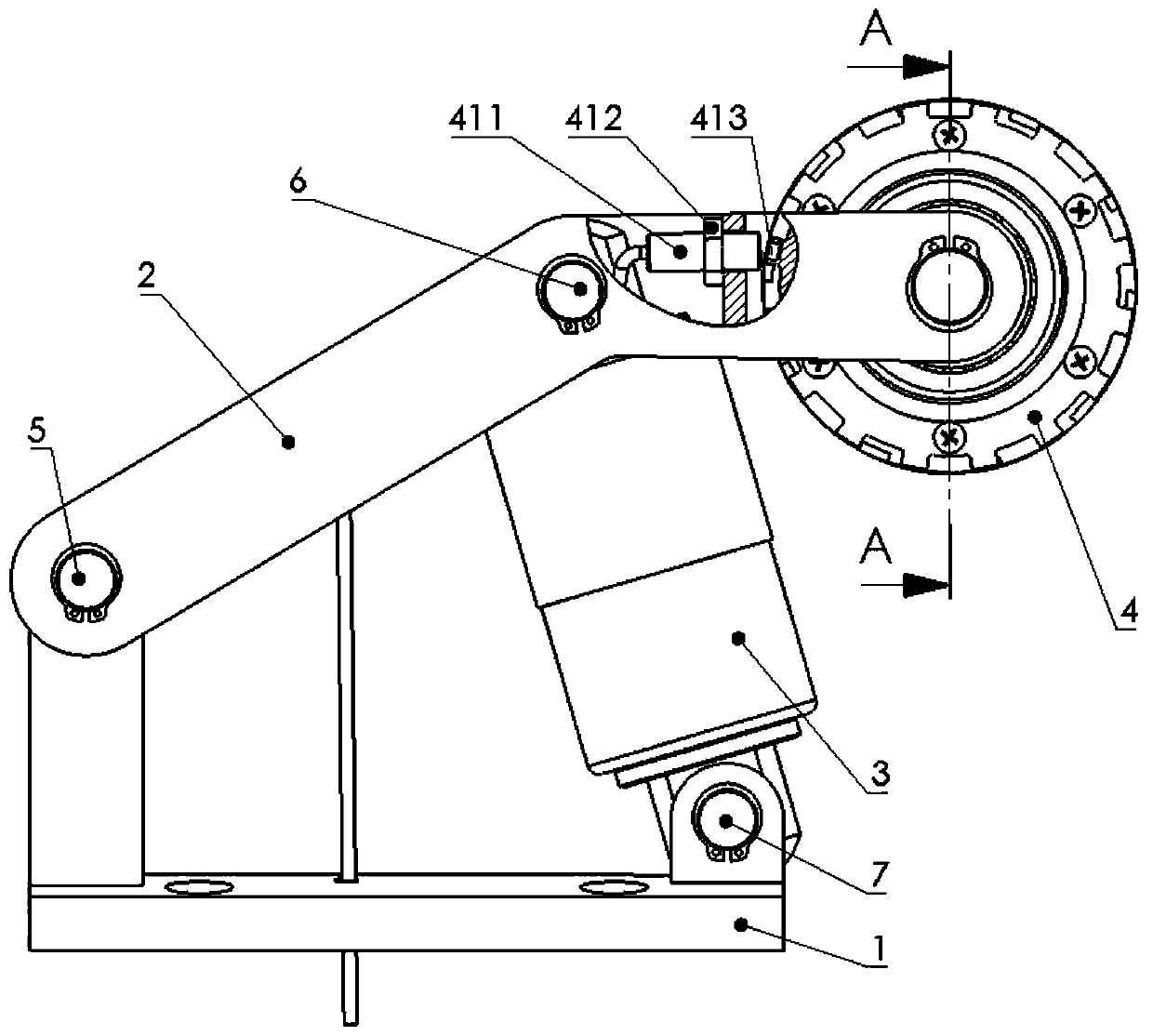

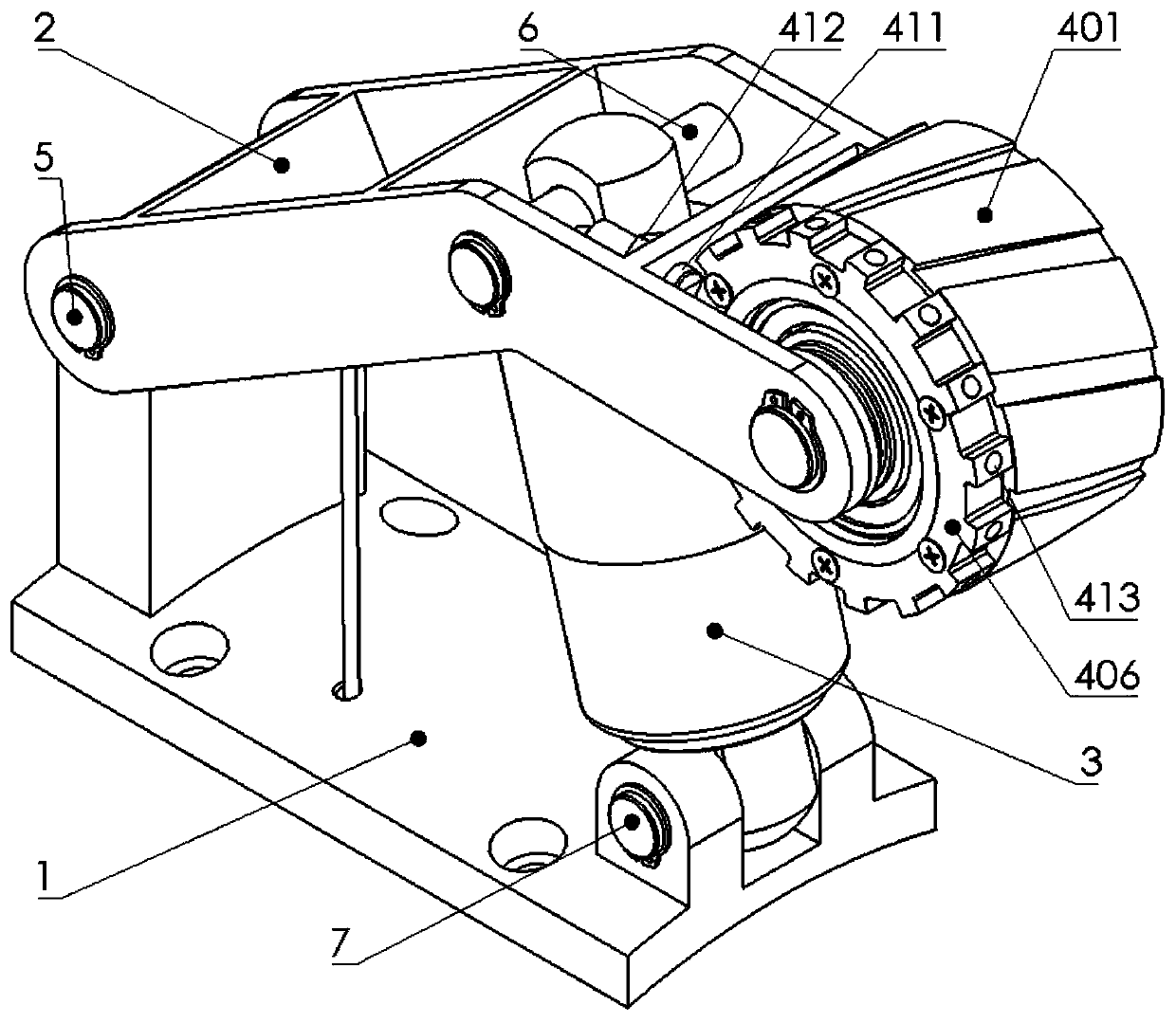

[0034] Such as Figure 2-3 As shown, a natural gas pipeline robot support and mileage measuring device of the present invention includes a base 1, a roller frame 2, an elastic support unit 3, and a speed measuring roller unit 4;

[0035] One end of the base 1 is movably connected to the lower end of the roller frame 2, and the other end is movably connected to the lower end of the elastic support unit 3, and the upper end of the elastic support unit 3 is movably connected to the middle part of the roller frame 2, and the roller frame 2 is provided with a plate ribs, the ribs are provided with through holes;

[0036] The speed measuring roller unit 4 includes roller 401, pin shaft IV 403, gear plate 406, permanent magnet block 413, deep groove ball bearing I 405, deep groove ball bearing II 410, left concave spherical sleeve 404, right concave spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com