Automatic material collection device

A material and automatic technology, applied in the stacking, transportation and packaging of objects, can solve the problems of large limitations, work intensity, high efficiency and cost, and achieve the effect of improving work efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

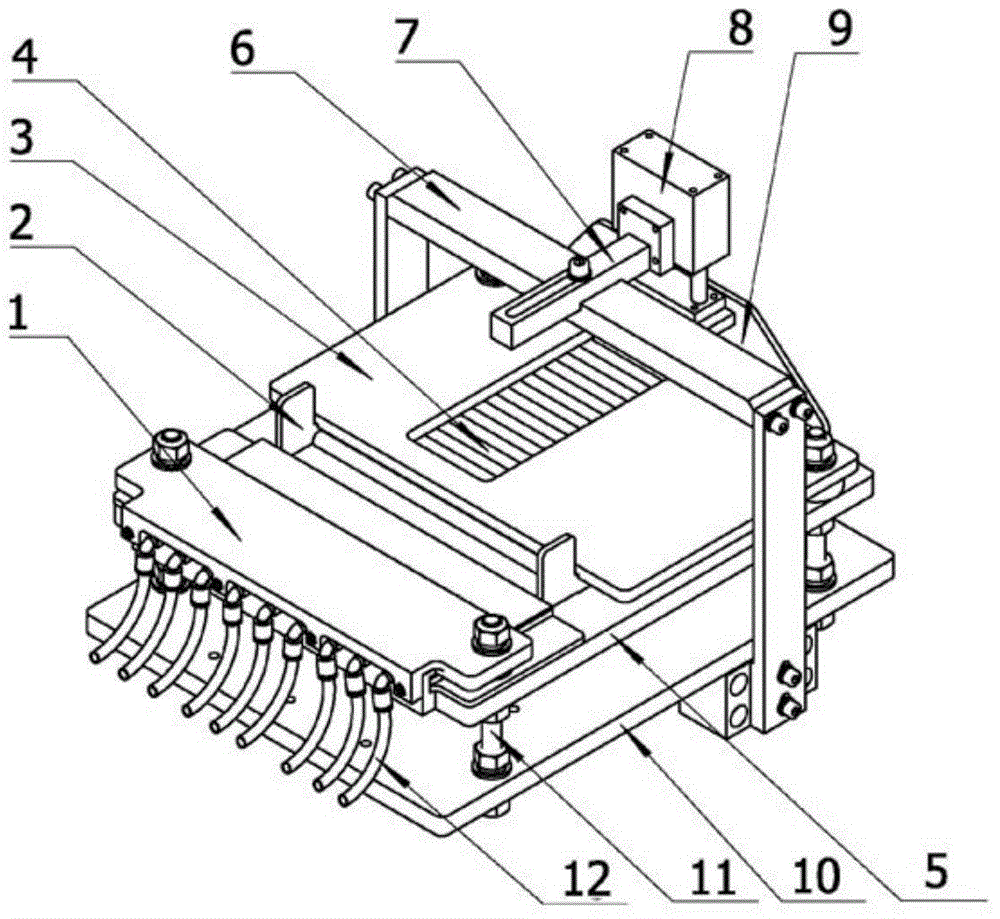

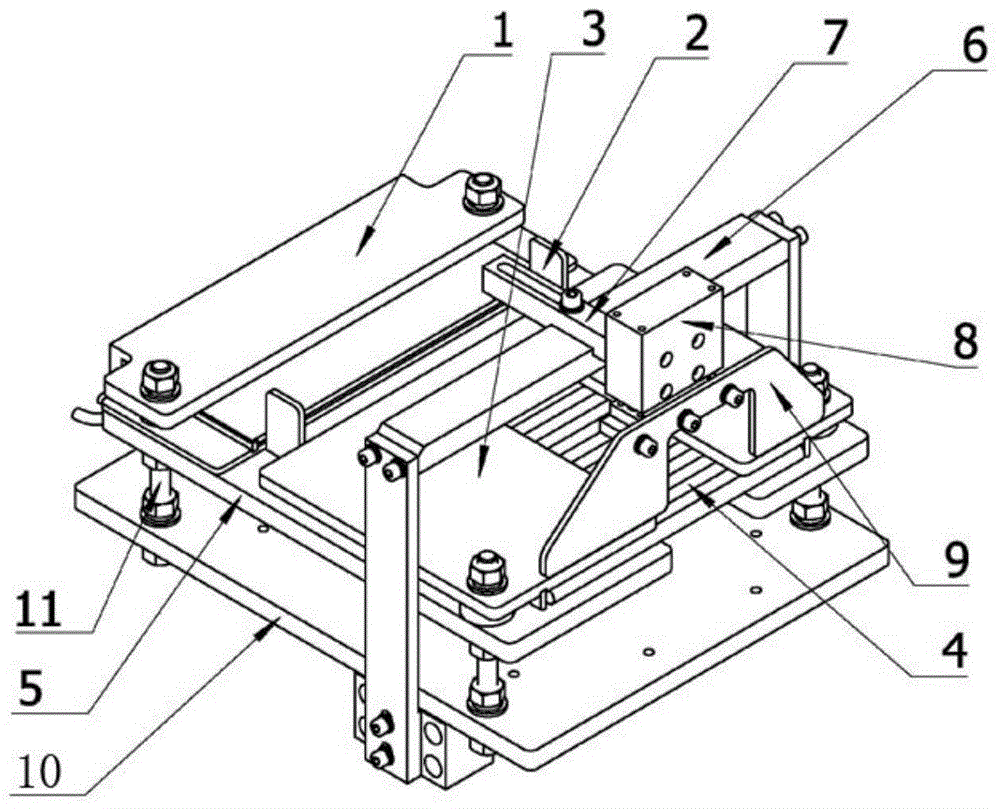

[0021] Such as figure 1 , figure 2 As shown, an automatic material collecting device includes an air blowing mechanism and a collecting mechanism. The collecting mechanism is provided with a cavity 4 for materials to pass through, and the blowing mechanism communicates with one end of the cavity 4 through the collecting channel. Among them, the air blowing mechanism includes an air outlet 1 and an air source, and the air outlet 1 communicates with the air source through an air pipe 12; Arranged in parallel up and down, a cavity 4 is formed between the upper bottom plate 5 , the upper cover plate 3 and the two side plates, and the other end of the cavity 4 is provided with a baffle plate 9 . The bottom of the air outlet 1 is fixed on the upper base plate 5, and the collection channel is formed between the air outlet 1, the upper base plate 5 and the collection mechanism cavity 4, and the restriction plates 2 are arranged on both sides of the collection channel.

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, an automatic material collecting device is mainly used for collecting tubular objects or columns, including an air blowing mechanism and a collecting mechanism. The collecting mechanism is provided with a cavity 4 for materials to pass through, and the blowing mechanism passes through The collection channel communicates with one end of the cavity 4 . Among them, the air blowing mechanism includes an air outlet 1 and an air source, and the air outlet 1 communicates with the air source through an air pipe 12; Arranged in parallel up and down, a cavity 4 is formed between the upper bottom plate 5, the upper cover plate 3 and the two side plates. The upper cover plate 3 is provided with a transparent glass window. The bottom of the air outlet 1 is fixed on the upper base plate 5, and the collecting channel is formed between the air outlet 1, the upper base plate 5 and the collecting mechanism cavity 4, and the restricting plates 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com