CF type servo interpolation shaft main shaft device for numerical control lathe

A technology of CNC lathe and spindle device, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., to ensure the effect of precise coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

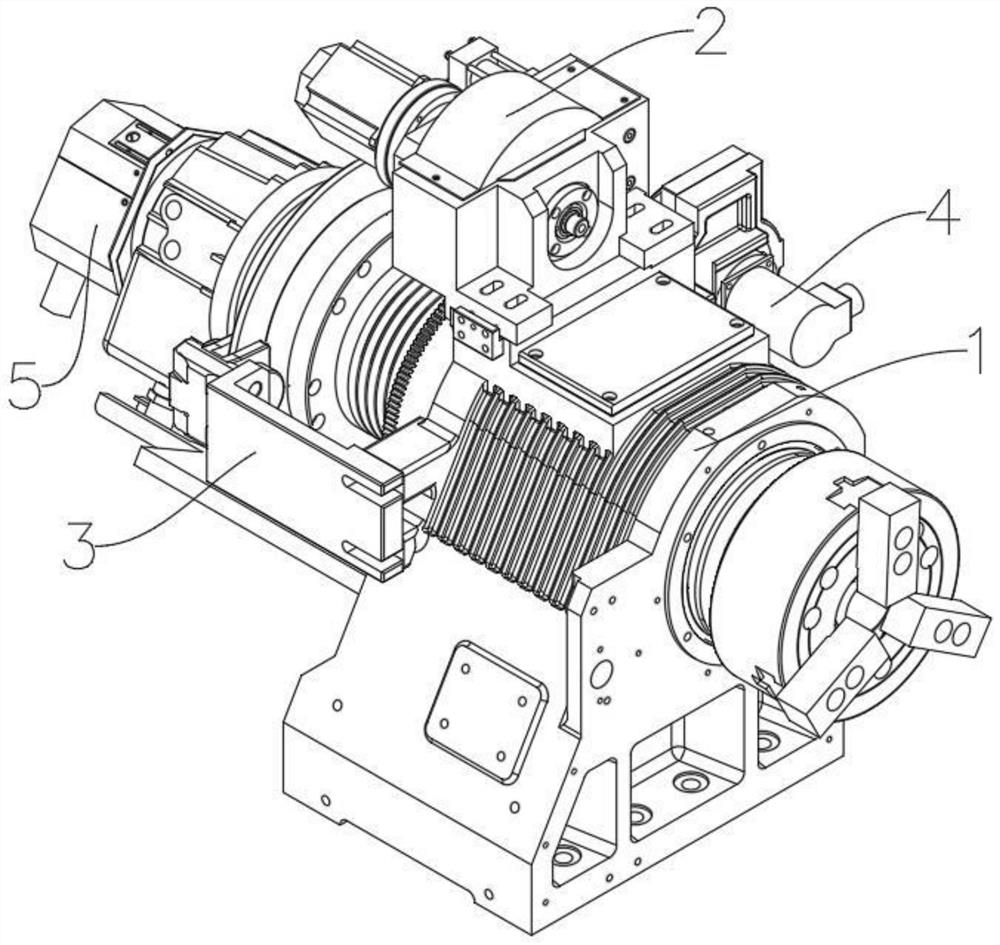

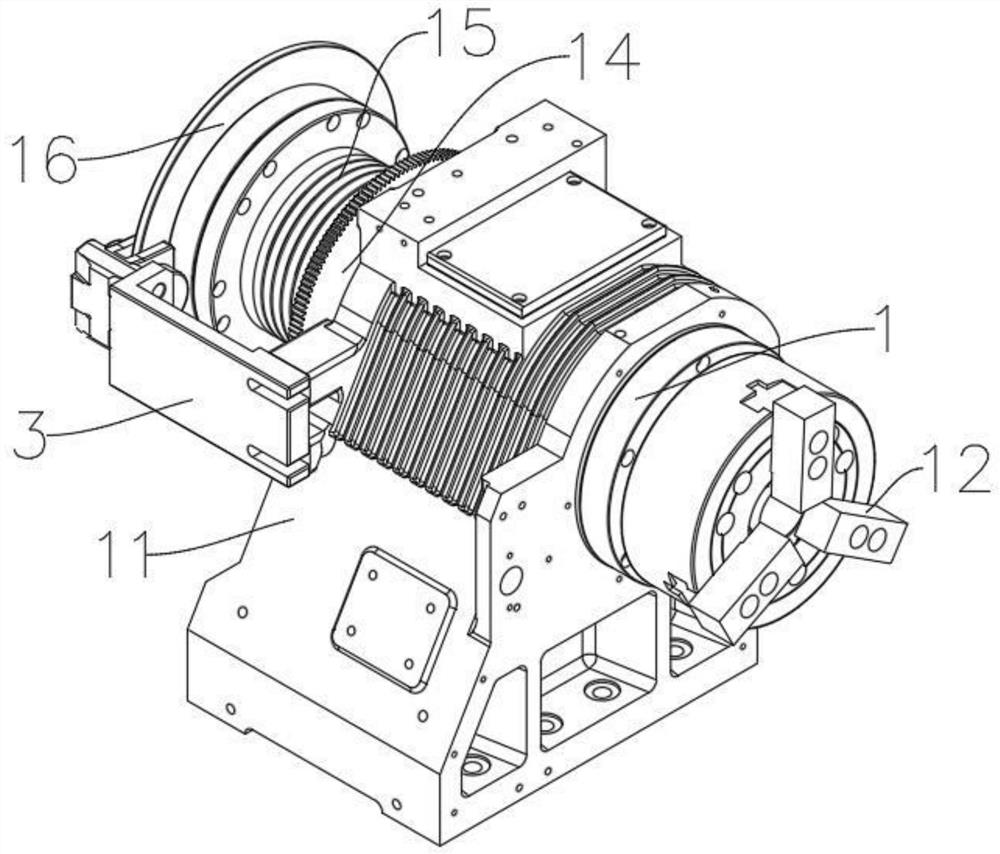

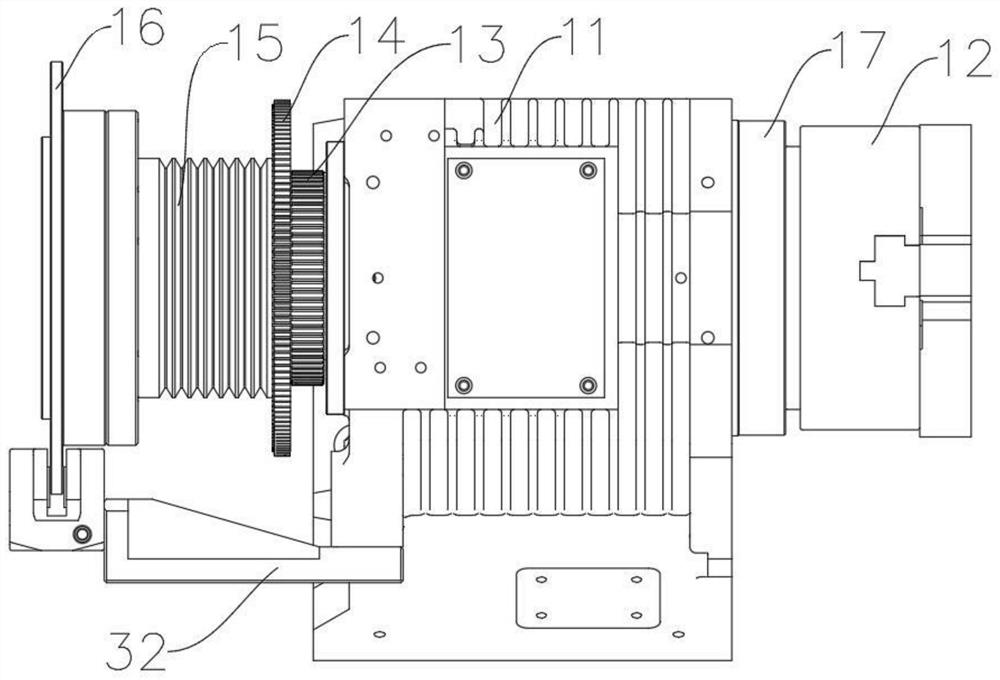

[0035] Such as Figure 1-8 As shown, the present invention provides a CF-type servo interpolation shaft spindle device for CNC lathes, which realizes fast and precise meshing of the driven gear plate 14 and the transmission gear 232, so as to change the rotation speed of the spindle 17, the gear Combined, the rotation of the main shaft 17 is converted from the main shaft motor drive to the motor 24 drive on the CF shaft mechanism 2, so that the main shaft 17 can be interpolated with other feed axes to process the contour curve, and the main shaft 17 can be turned, milled, drilled, tapped, The working status of various processing techniques such as silk.

[0036] Technical scheme of the present invention is:

[0037] The invention provides a CF typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com