Intelligent fire extinguisher cabinet and working method thereof

A technology for fire extinguisher boxes and fire extinguishers, which is applied to electric fire alarms, fire alarms that rely on smoke/gas effects, and instruments to achieve the effects of collection, difficulty, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

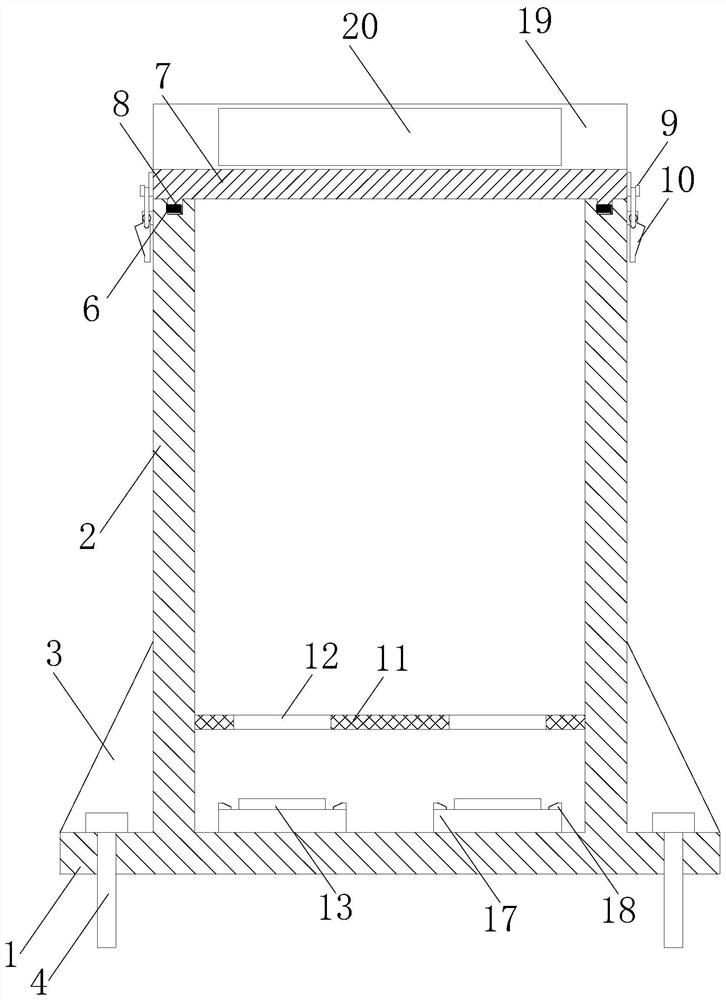

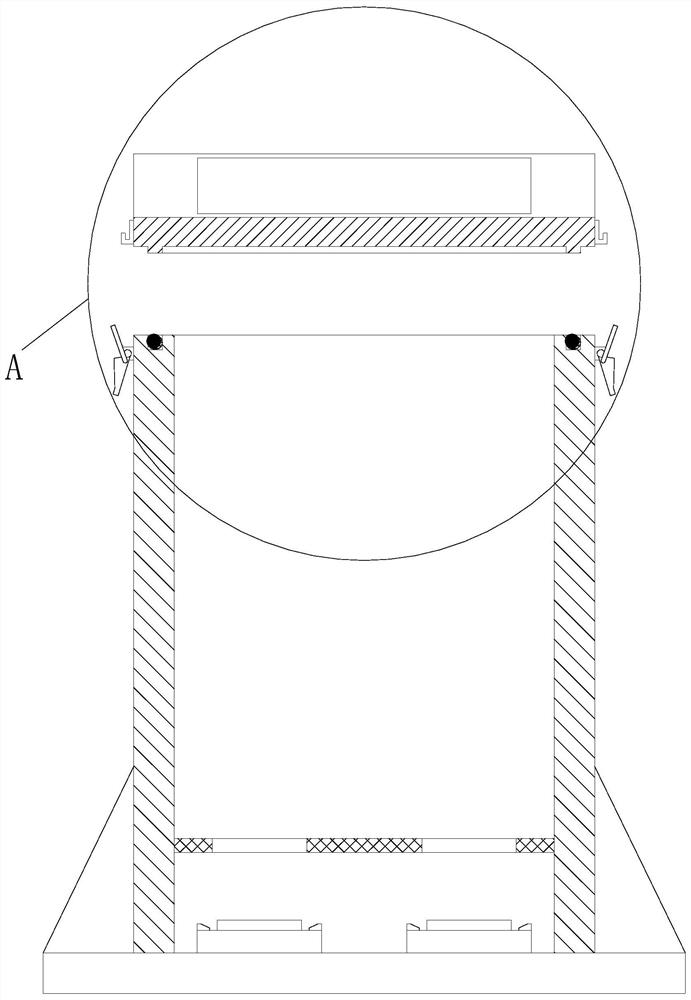

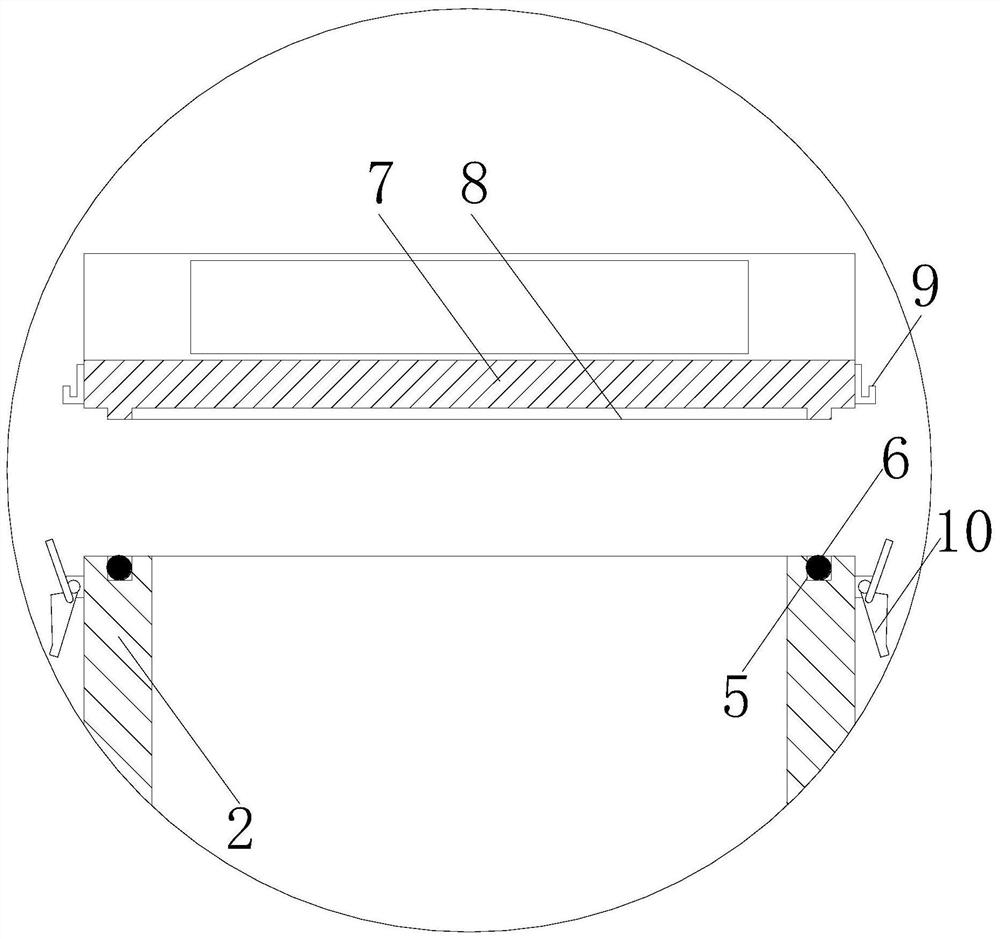

[0048] The intelligent fire extinguisher box with weight monitoring, as shown in the figure, includes an extension plate 1, a box body 2, a rib plate 3, a ground nail 4, an annular groove 5, a sealing ring 6, an end cover 7, an annular convex strip 8, and a hook 9 , a lock 10, a grid 11, a through hole 12, an electronic scale 13, wherein an extension plate 1 is provided at the bottom end of the outer wall of the box body 2, and a rib plate 3 is fixedly connected between the extension plate 1 and the box body 2, and the ground The nail 4 penetrates the epitaxial plate 1 and is anchored to the ground. There is an annular groove 5 at the top of the box body 2, and a sealing ring 6 is built in the annular groove 5. There is an annular convex strip 8 at the lower end of the end cover 7. A hook 9 is fixedly connected to the outer wall, a lock 10 is fixedly connected to the outer wall of the box body 2, the end cover 7 is buckled on the top of the box body 2, the lock 10 is snapped an...

Embodiment 2

[0051] Smart fire extinguisher box with weight monitoring, such as Figure 1~5 As shown, it includes epitaxial plate 1, box body 2, rib plate 3, ground nail 4, annular groove 5, sealing ring 6, end cover 7, annular convex strip 8, hook 9, lock buckle 10, grid frame 11, through hole 12. Electronic scale 13, wherein an extension plate 1 is provided at the bottom end of the outer wall of the box body 2, a rib plate 3 is fixedly connected between the extension plate 1 and the box body 2, and ground nails 4 penetrate the extension plate 1 and are anchored to the ground, There is an annular groove 5 at the top of the box body 2, a sealing ring 6 is built in the annular groove 5, and an annular convex strip 8 is provided at the lower end of the end cover 7, and a hook 9 is fixedly connected to the outer wall of the end cover 7. The outer wall of 2 is fixedly connected with a lock 10, the end cover 7 is buckled on the top of the box body 2, the lock 10 is snapped and fixed with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com