Presser foot used for bartack sewing machine

A tacking machine and presser foot technology, which is applied in the field of tacking machines, can solve the problems of not being able to effectively press the cloth and slipping of the cloth, and achieve good cloth pressing effect, avoid scratches, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

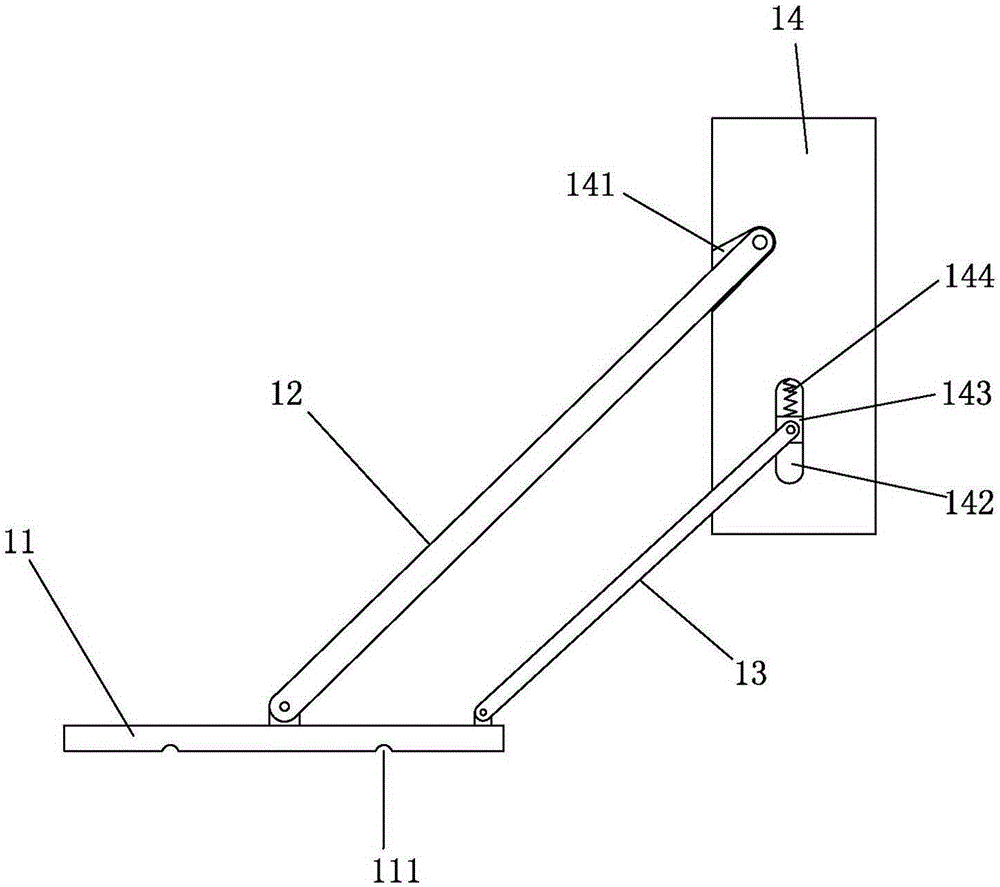

[0017] Example: such as figure 1 As shown, the presser foot 1 includes a presser foot seat 14 and a presser foot plate 11 , and the presser foot seat 14 is connected to the transmission rod 2 . Presser foot seat 14 and presser foot plate 11 are provided with presser bar 12 and connecting rod 13, one end of presser bar 12 is hinged on presser foot seat 14, and the other end is hinged at the middle part of presser foot plate 11, and presser foot plate 11 follows presser bar 12 Rotate relative to the presser foot seat 14, the rotation angle of the pressure rod 12 is a rotation angle a, and the rotation angle a is 1°-5°. The presser foot seat 14 is provided with a rotating groove 141, and one end of the pressing rod 12 is hinged in the rotating groove 141. The rotating groove 41 is provided with a rib that limits the rotation angle of the pressing rod 12. The angle between the two ribs is the same as that of the pressing rod 12 The corner a is the same. One end of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com