Multi-floating-body sea wave two-stage conversion power-generating device

A power generation device and ocean wave technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as low reliability, inability of power generation systems to well apply wave energy development and utilization, weak storm resistance, etc., to achieve Reduce manufacturing and maintenance costs, facilitate large-scale production and utilization, and improve energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

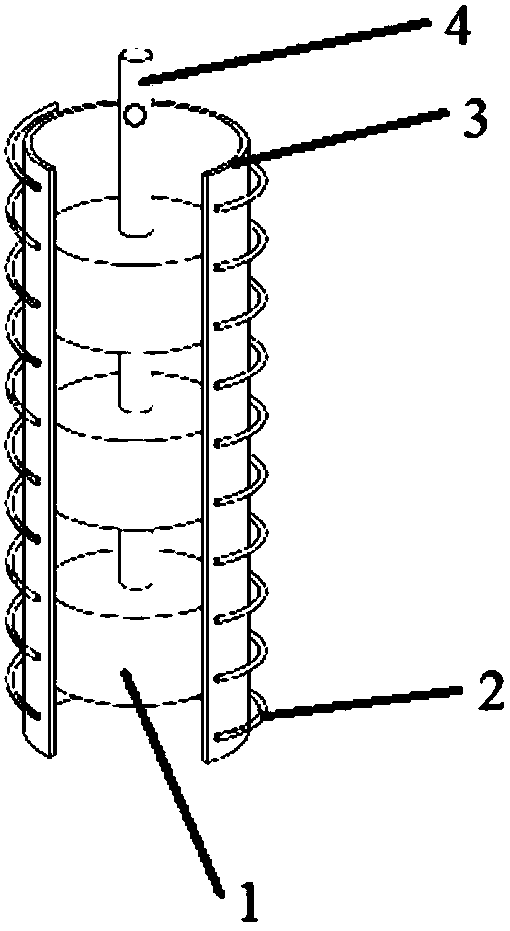

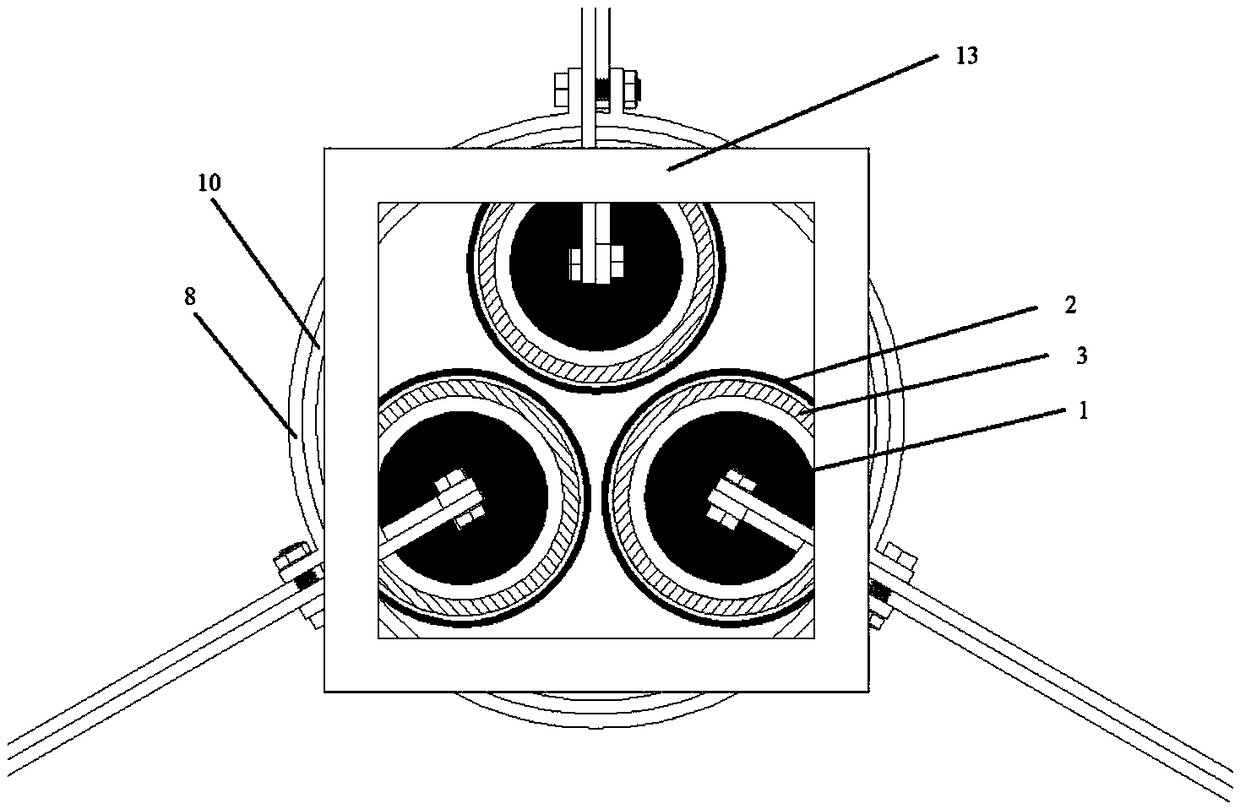

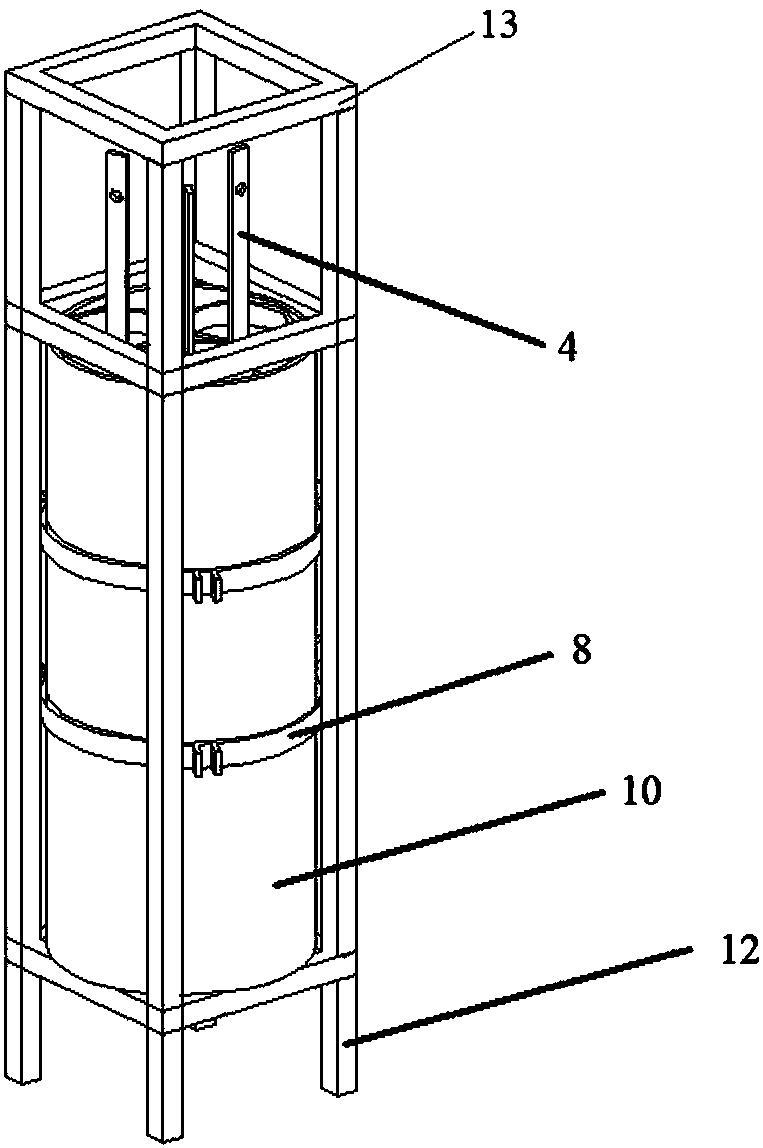

[0036] This embodiment is a multi-floating body wave secondary conversion power generation device with three power generation units, the structure is as follows Figure 1-6 As shown, it is composed of wave direct drive power generation part, power transmission mechanical part, foam buoy 11 and support frame 12. The wave direct drive power generation part is composed of three power generation units and cylindrical anti-corrosion plastic power generation bucket 10. The power transmission mechanical part Three groups of floats are correspondingly arranged corresponding to the generating units. Each power generation unit is composed of three cylindrical NdFeB strong magnet blocks 1 fixed in series on the same magnet connecting rod 4 at equal intervals to form a mover, and a copper coil 2 spirally wound on a plastic coil cylinder 3 to form a mover. Stator composition. The three coil cylinders wound with copper coils are placed upright and the lower end is fixed on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com