Expanding mechanical air suction control device

A technology of a control device and an expansion cylinder, applied in the field of expansion machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

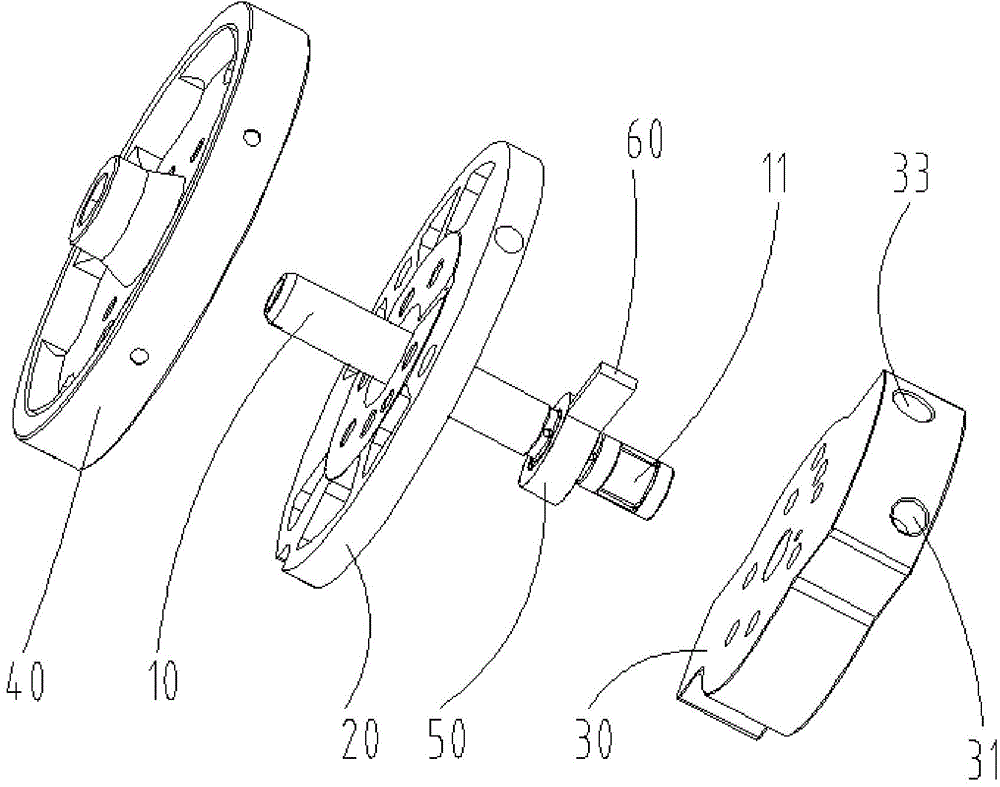

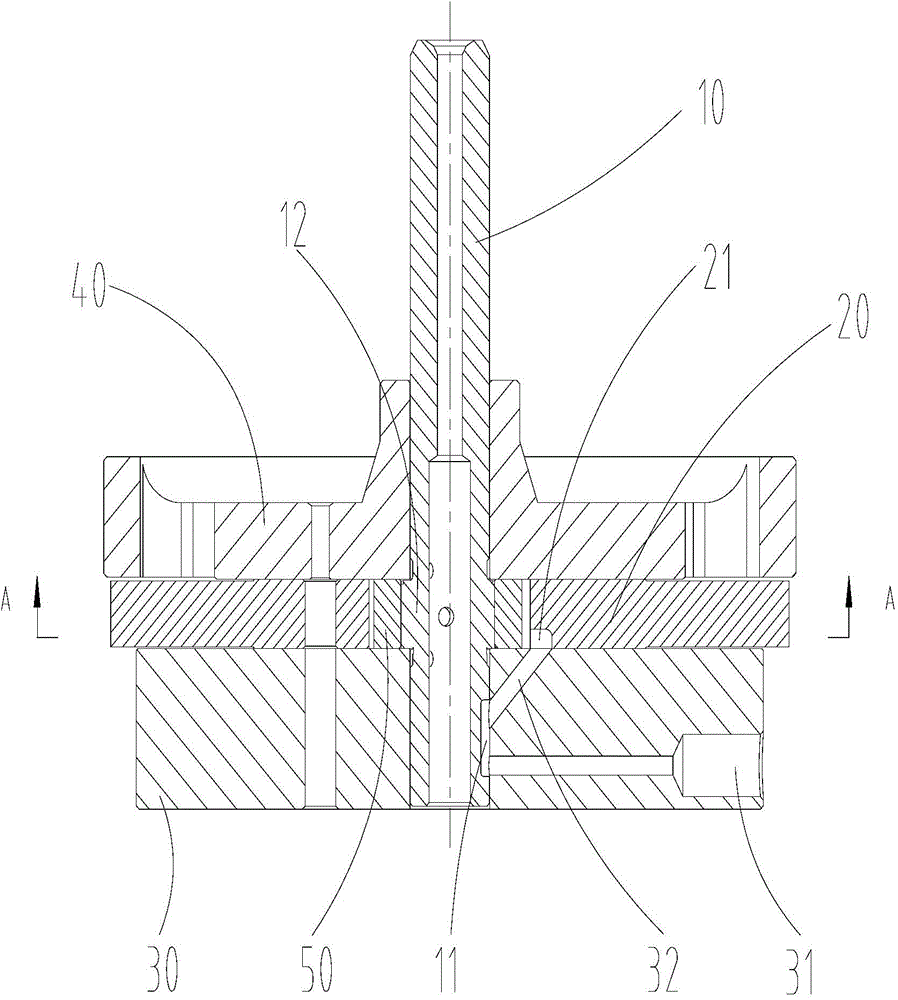

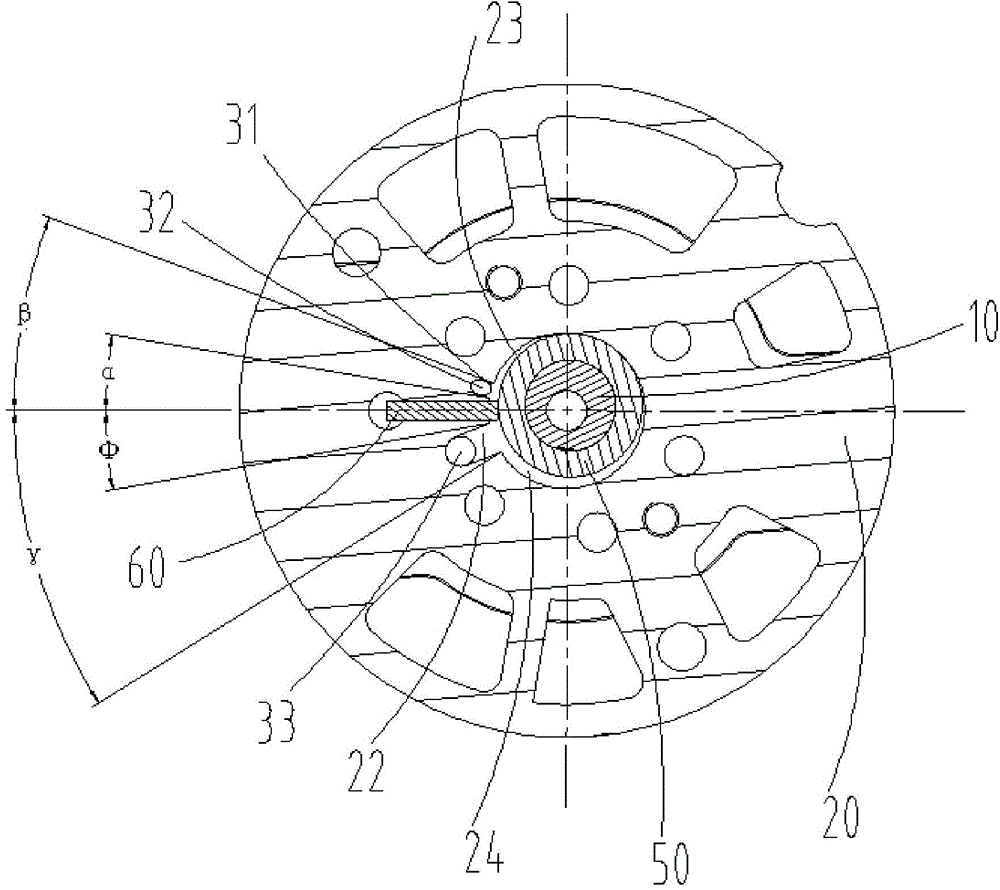

[0025] combine Figure 1 to Figure 5 As shown, according to the embodiment of the present invention, an expansion mechanical suction control device is provided. The expansion mechanical suction control device includes a crankshaft 10 , an expansion cylinder 20 , a first flange 30 and a second flange 40 . Among them, the expansion cylinder 20 is sleeved on the crankshaft 10; the first flange 30 is sleeved on the crankshaft 10 and is located on the first side of the expansion cylinder 20; the second flange 40 is sleeved on the crankshaft 10 and is located on the expansion cylinder 20 on the second side. In order to reduce and prevent the crankshaft 10 from moving in the axial direction, the arrangement of the high-pressure fluid channel of the expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com