Clamping and sealing clamp for end of pipe

A pipe and fixture technology, which is applied in the field of pipe end clamping and sealing structure, can solve the problems that pipe clamping and sealing cannot be effectively combined, affect the accuracy of pipe performance experiments, and it is difficult to carry out experiments smoothly, so as to simplify the preparation work, The effect of uniform clamping force distribution and easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

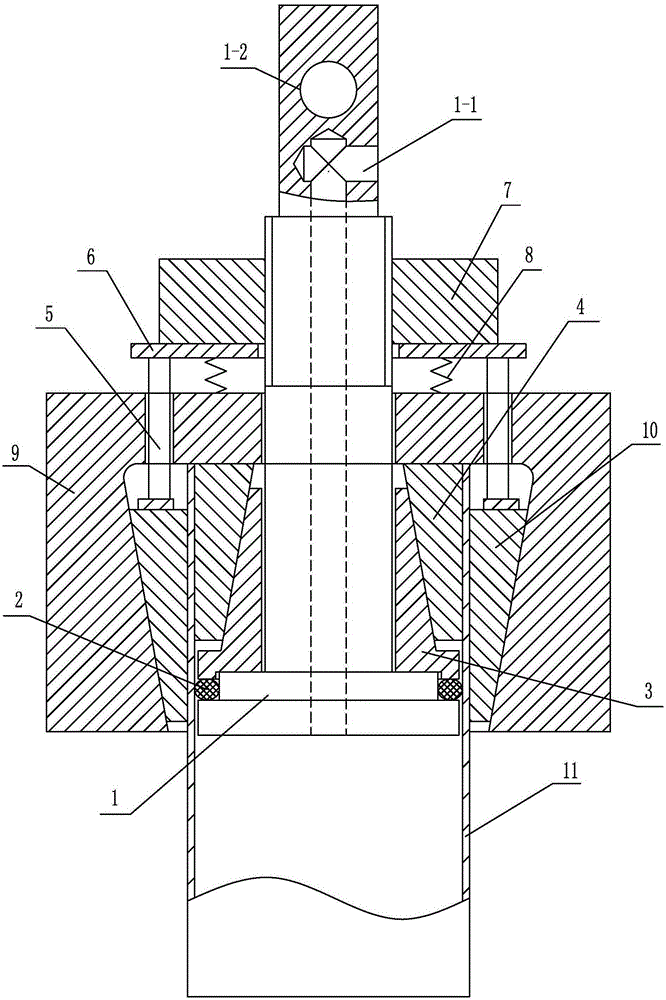

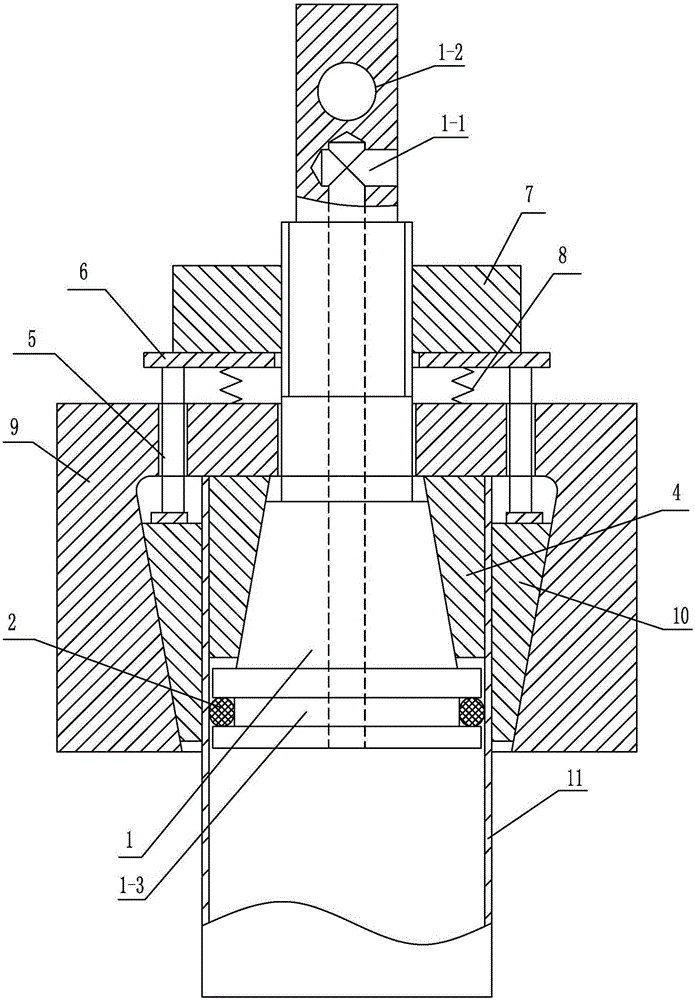

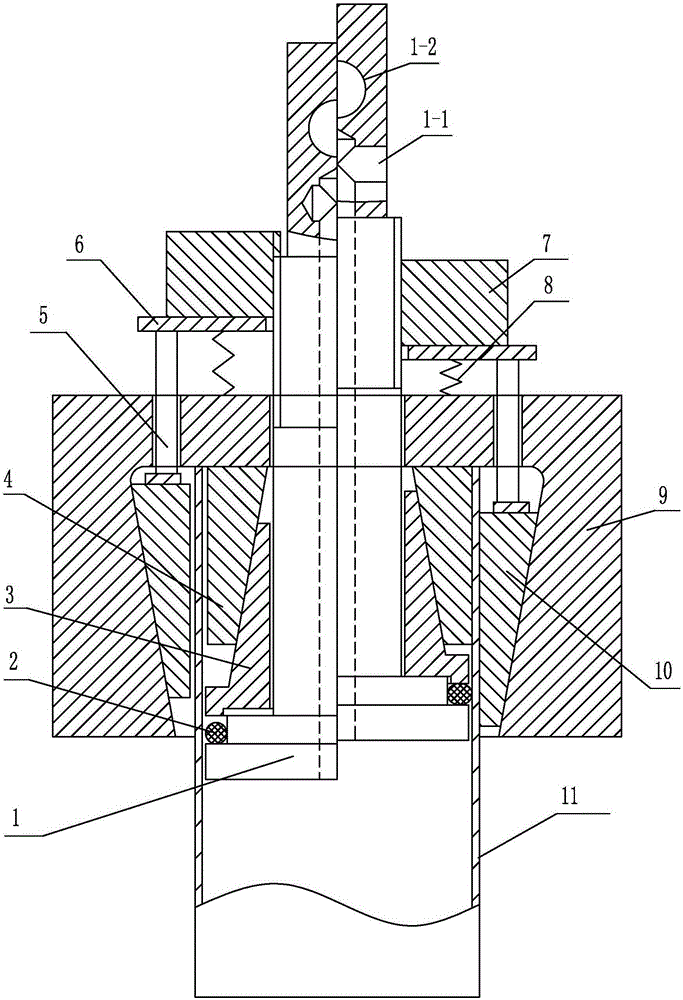

[0010] Specific implementation mode one: combine figure 1 and image 3 Explain that a pipe end clamping and sealing fixture in this embodiment includes a mandrel 1, a sealing ring 2, a wedge block 3, a supporting plate 6, a screw 7, an elastic element 8, an outer collar 9, and N Wedge-shaped inner jaws 4, N wedge-shaped outer jaws 10 and N ejector pins 5; wherein N is a positive integer, and 8≥N≥3; the mandrel 1 is a mandrel with a liquid-filled channel, and one end of the mandrel 1 is two Stepped structure, the other end of the mandrel 1 is processed with a liquid filling port 1-1 connected with the liquid filling channel; the middle section of the mandrel 1 is processed with external threads;

[0011] The screw 7 is threadedly connected to the middle section of the mandrel 1, and the mandrel 1 is covered with an outer collar 9, and a wedge block 3, N wedge-shaped inner jaws 4 and N Wedge-shaped outer claws 10; wedge-shaped blocks 3 are inserted on the mandrel 1, N wedge-sh...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 and image 3 Note that the elastic element 8 in this embodiment is a coil spring. With such arrangement, it is cheap and easy to obtain, and convenient to use and disassemble. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 and image 3 Note that the sealing ring 2 of this embodiment is an O-ring. With such arrangement, it is cheap and easy to obtain, simple in structure and convenient to use. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com