Clamping device for a crawling robot

A crawling robot and clamping device technology, which is applied in the field of automation, can solve the problems of limited flexibility in use, the overall weight of the robot, and complex equipment structure, and achieve the effects of easy maintenance, convenient installation and removal, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

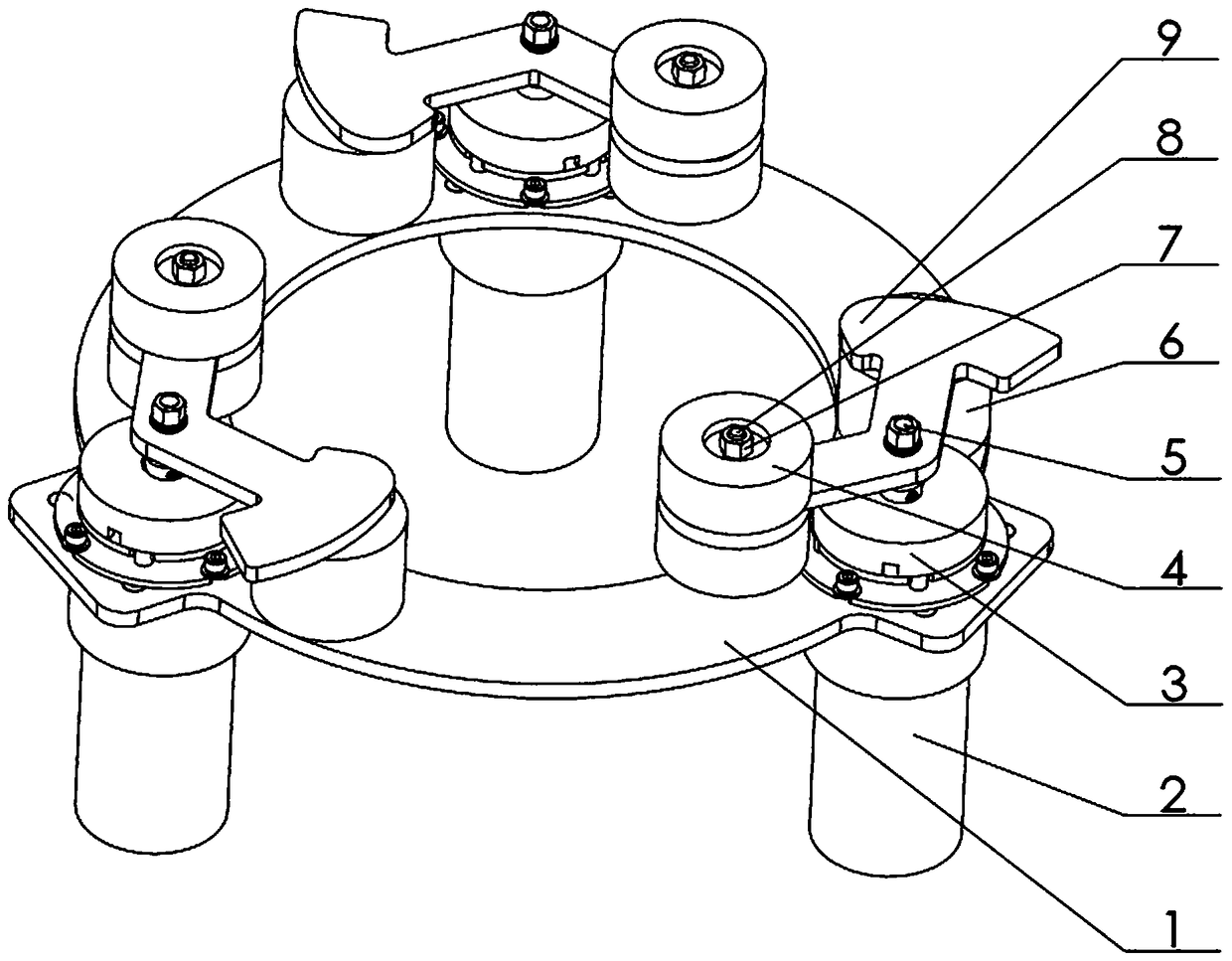

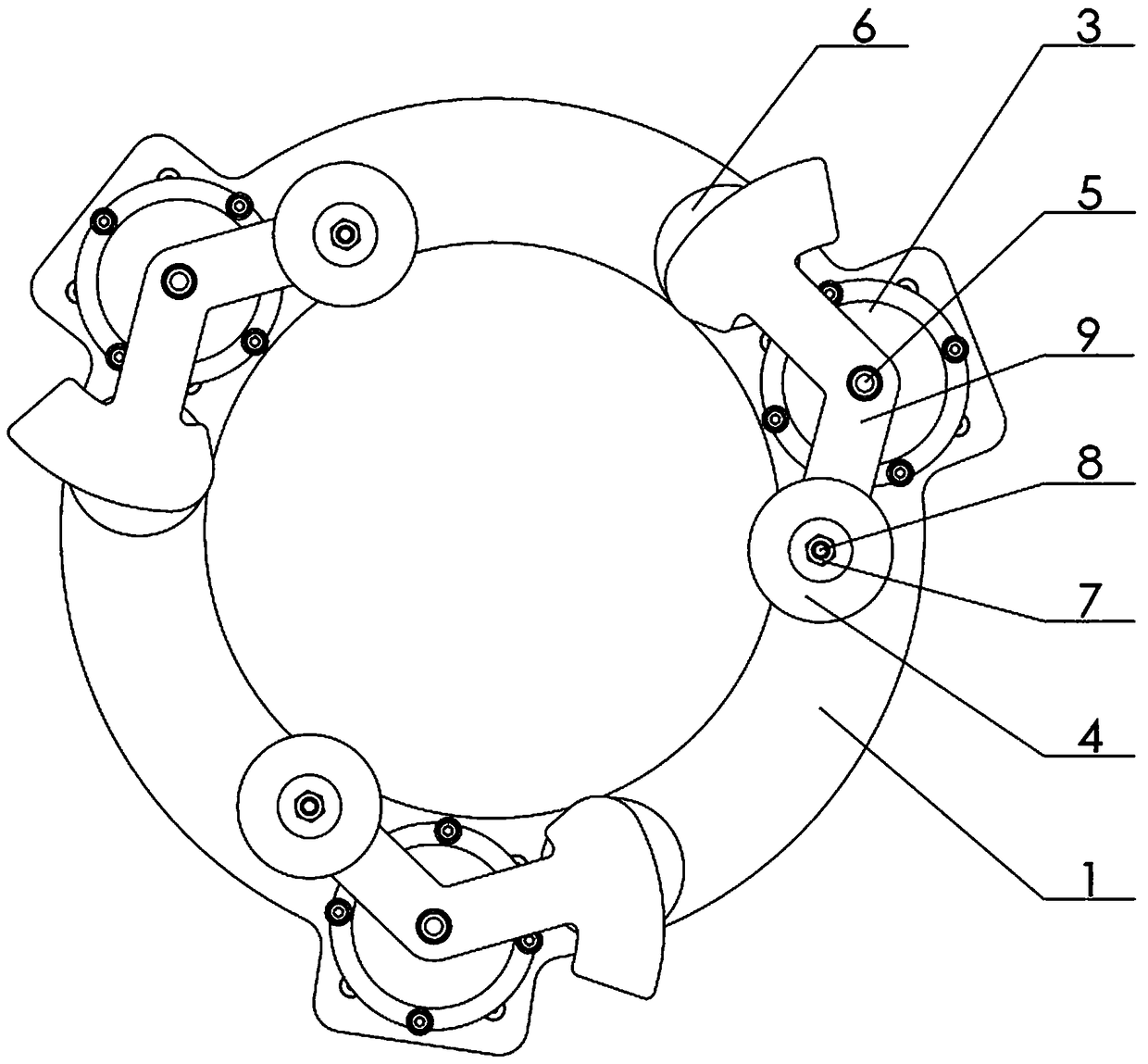

[0028] refer to Figure 1-2 , a clamping device for a crawling robot, which consists of a bracket 1 and three groups of electromagnetic clamping mechanisms evenly distributed on the bracket 1 in the circumferential direction.

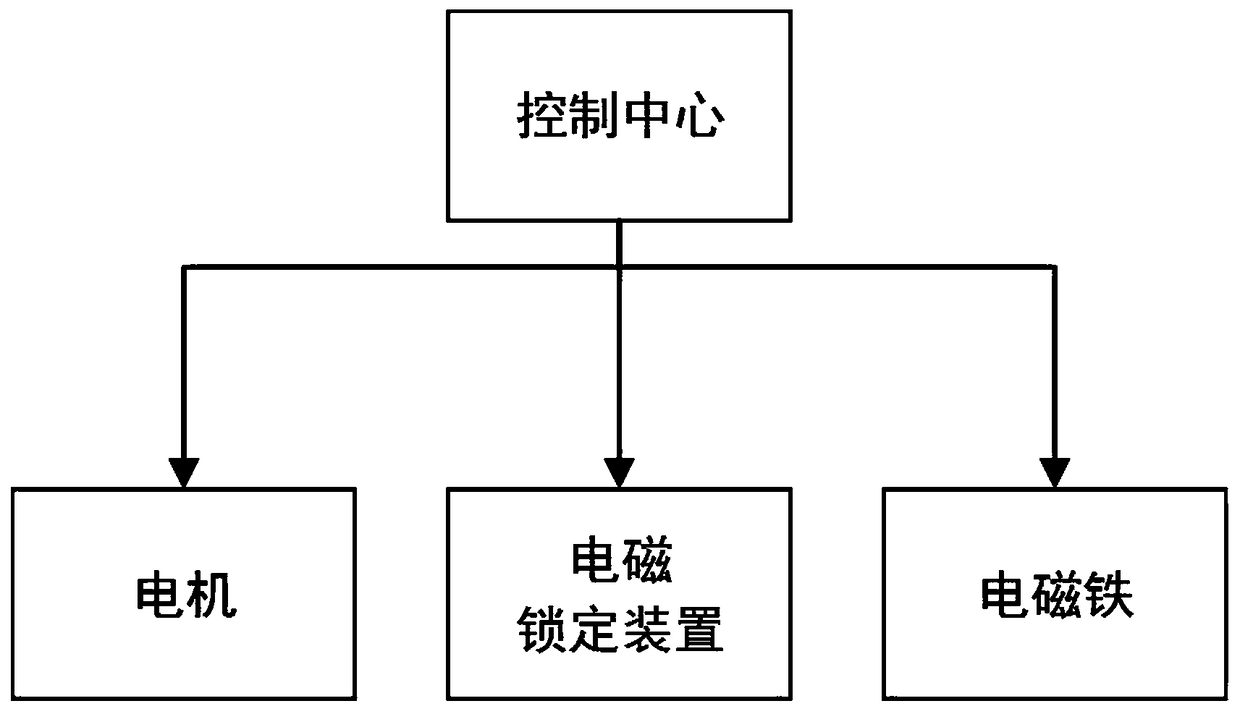

[0029] Each group of electromagnetic clamping mechanism is composed of motor 2, electromagnetic locking device 3, rubber block 4, motor spindle 5, electromagnet 6, nut 7, bolt 8, L-shaped connecting rod 9, the motor 2 is installed at the lower end of the bracket 1, The electromagnetic locking device 3 is installed on the upper end of the bracket 1, and the motor passes through the bracket 1 sequentially through the motor main shaft 5, and is connected with the electromagnetic locking device 3 and the L-shaped connecting rod 9, and the two sides of one end of the L-shaped connecting rod 9 pass through bolts 8 and nuts 7 respectively. A rubber block 4 is fixed, and the other end is an arc-shaped structure, and the center of the arc-shaped structure coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com