Clamping device for ore conveying pipe laying work in deep-sea mining

A technology for conveying pipelines and deep-sea mining. It is applied in the directions of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve the problem of low safety and reliability of laying and recycling operations, and achieve the effect of safe and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

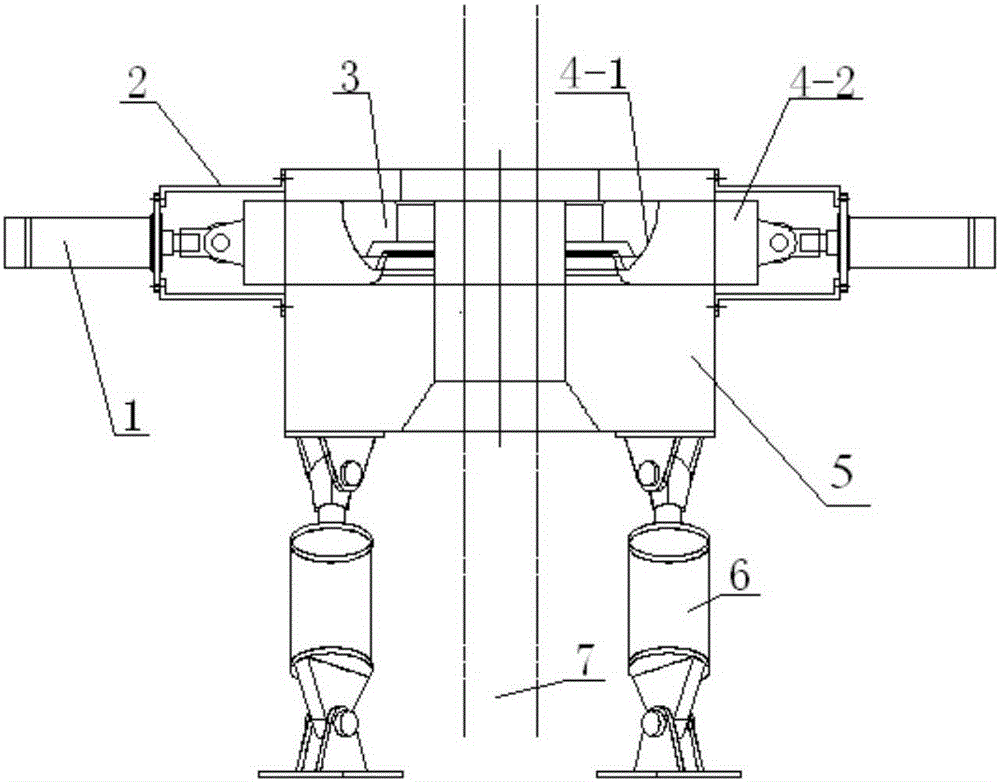

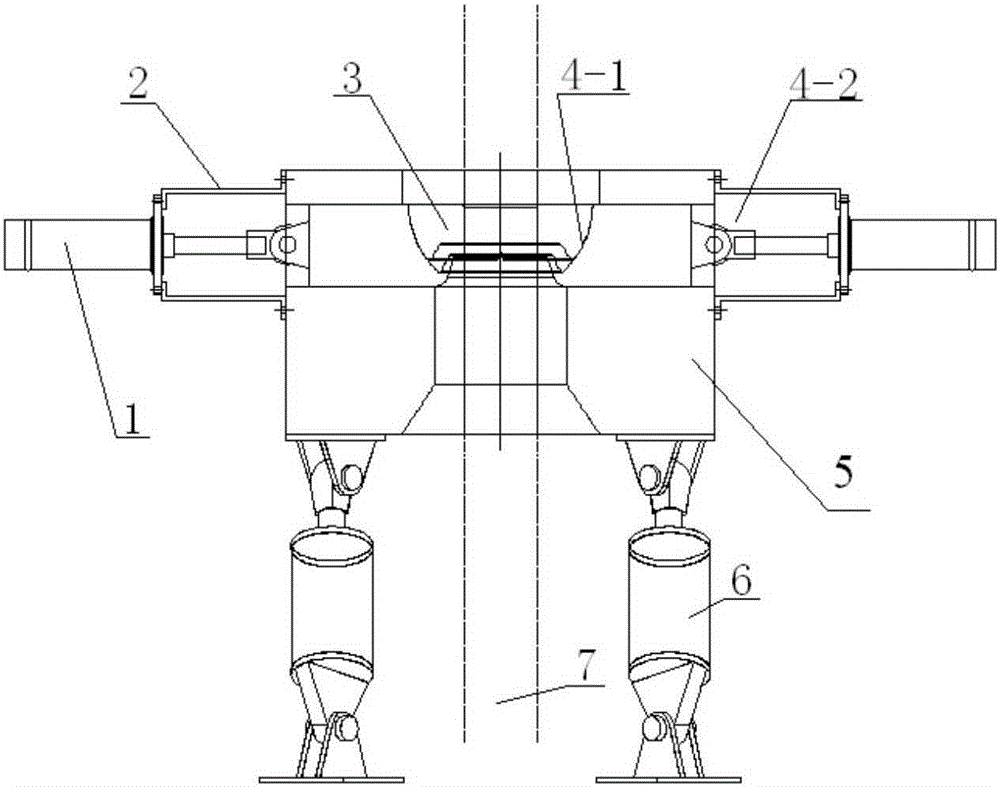

[0017] combine figure 1 and figure 2 As shown, the clamping device for the laying operation of the ore conveying pipeline in deep-sea mining includes a Carmen base 5, two Carmen sliders 4-2 respectively located in two chutes on the Carmen base 5, and a Carmen slider 4-2. A ball hinge support 4-1 is arranged on the block 4-2, and the ball hinge support 4-1 is connected with a hemispherical ball hinge 3, and drives the hydraulic cylinder 1 and the installation base 2 of the door slider 4-2 to open and close, and the hydraulic heave compensator6. The hydraulic cylinder 1 and its installation base 2, the card door slider 4-2, the ball hinge support 4-1 and the ball hinge 3 are symmetrically arranged on the card door base 5, and the lower part of the card door base 5 is connected to the hydraulic heave compensator 6, The base of the heave compensator 6 is located on the working platform of the mother ship on the water surface.

[0018] When laying the pipeline 7, use the sling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com