Loading head for bending moment and torque synchronous loading without interference

A technology of torque loading and bending moment loading, which is applied in the field of loading head, can solve the problems that the bending moment and torque synchronous loading do not interfere with each other, and the loading device cannot eliminate the mutual interference of torque and bending moment, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

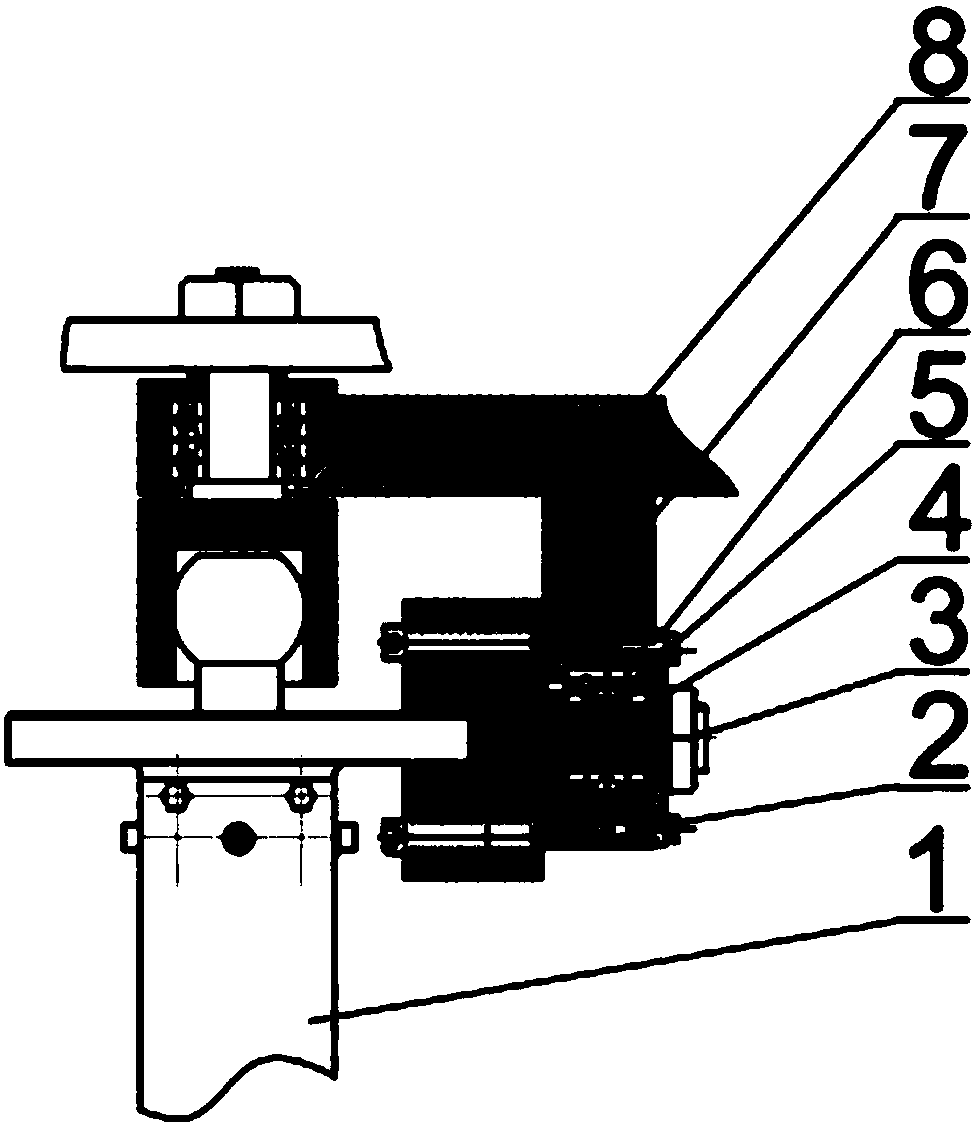

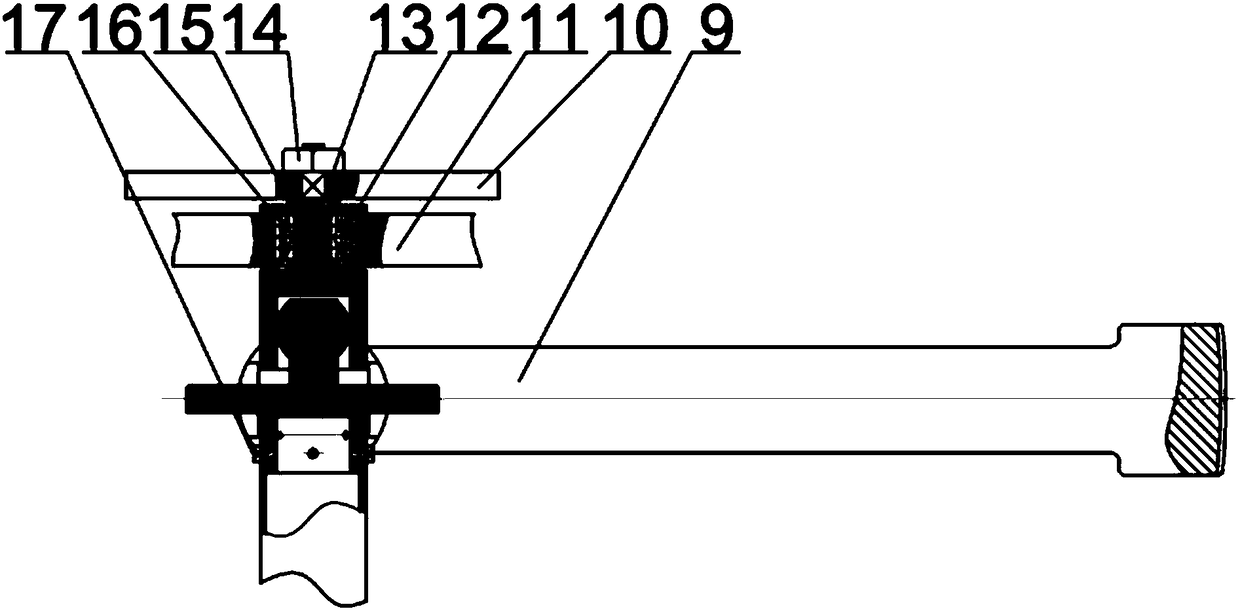

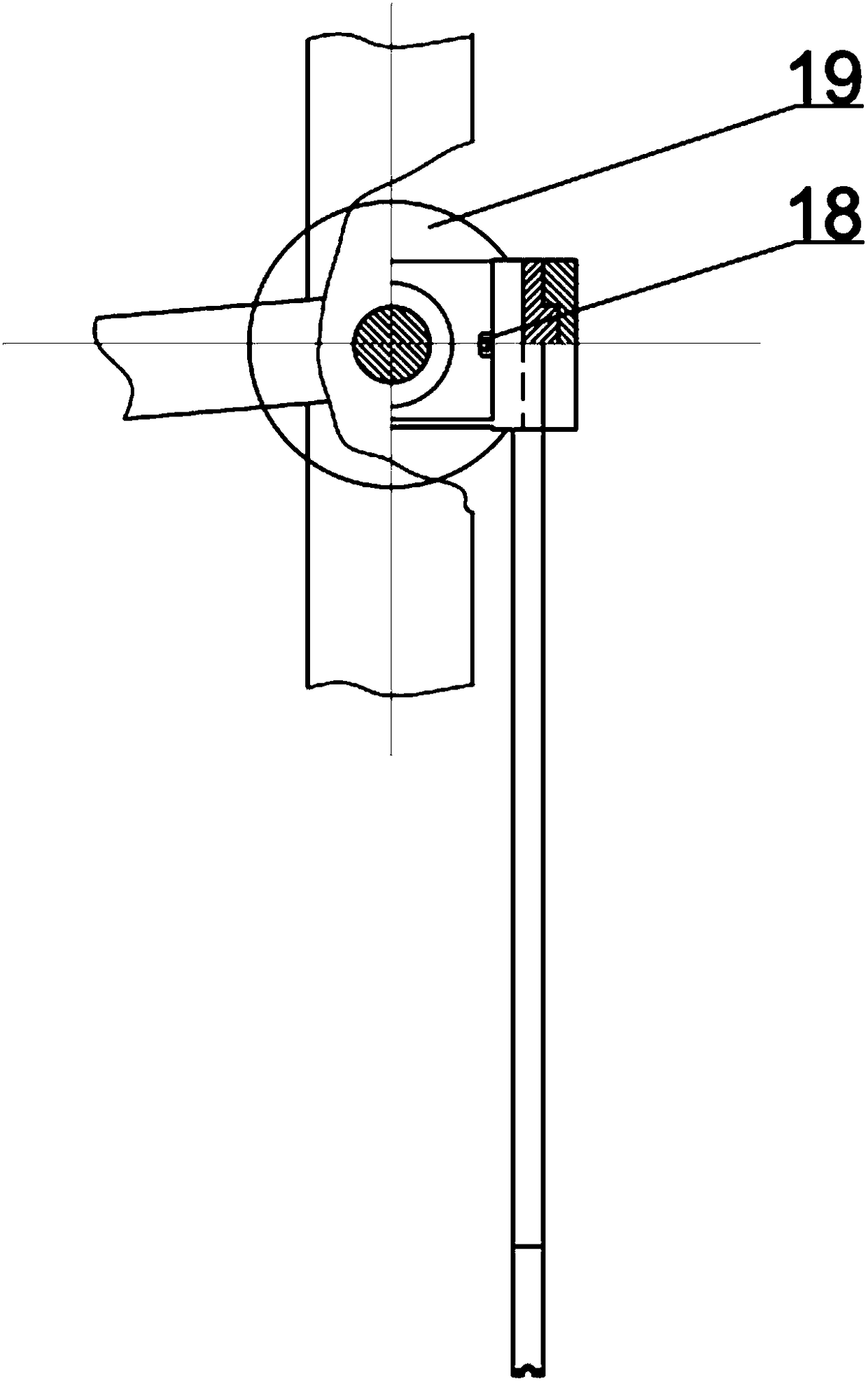

[0021] A loading head that realizes synchronous loading of bending moment and torque without interfering with each other, such as Figure 1 to Figure 3 As shown, the loading head includes an axisymmetric torque loading arm 10, and the axisymmetric torque loading arm 10 is installed on the top of the torque loading connector 13 through a nut 214; the bottom of the torque loading connector 13 is fixedly installed with a loading Flange 19; the bottom of the loading flange 19 is used to install the measured part 1; the torque loading connector 13 is fixedly installed with a crossbeam 11 and a T-beam 8; the bottom end of the T-beam 8 is bent The moment loading connector 7 is equipped with a bending moment loading arm 9 . Wherein, the part under test 1 is fixedly installed on the bottom of the loading flange 19 by bolts 2.

[0022] The torque loading connector 13 includes a columnar part and an n-type part; the columnar part is arranged on the upper part of the n-type part. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com