Distributed control method of automatic manufacturing system

A technology of automatic manufacturing system and distributed control, applied in manufacturing computing system, comprehensive factory control, comprehensive factory control and other directions, can solve problems such as affecting system performance, increasing system complexity, reducing system permissibility, etc., to achieve large permissibility , to ensure the effect of no deadlock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

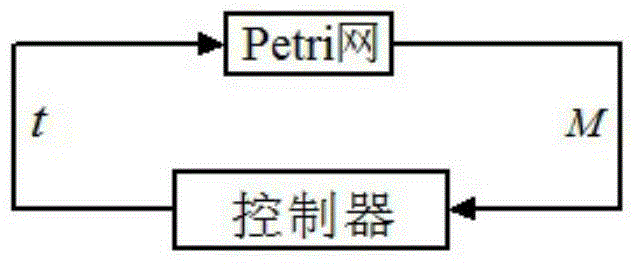

[0033] The system in the present invention refers to a system that has both flexible processing paths and assembly operations, more specifically, embeds assembly operations into flexible processing paths, and the invention is an online, real-time distributed control method.

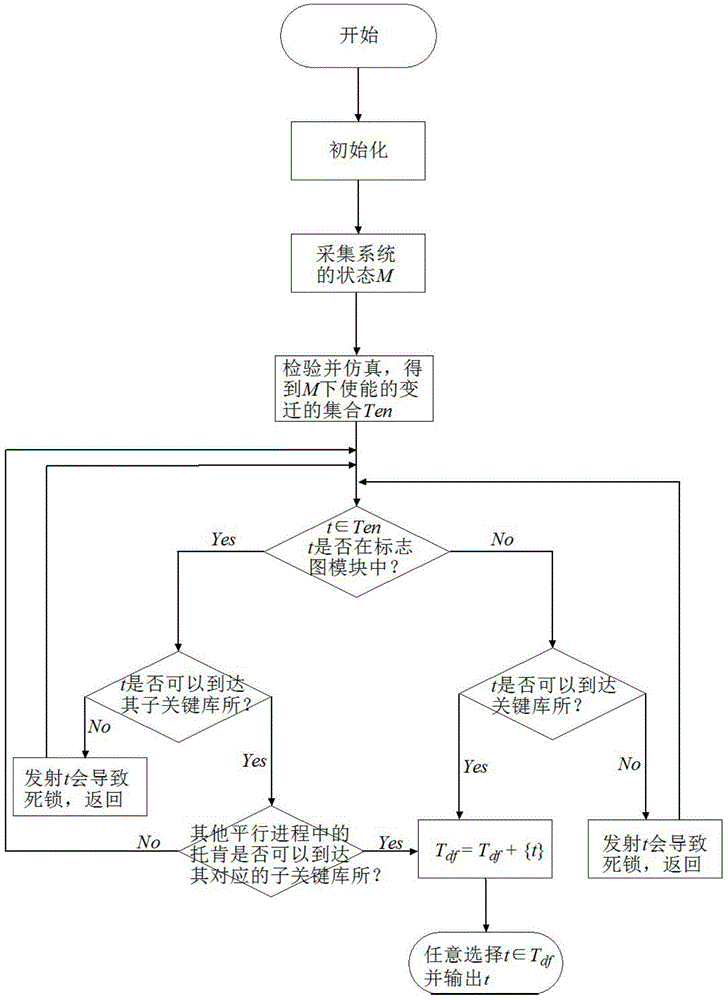

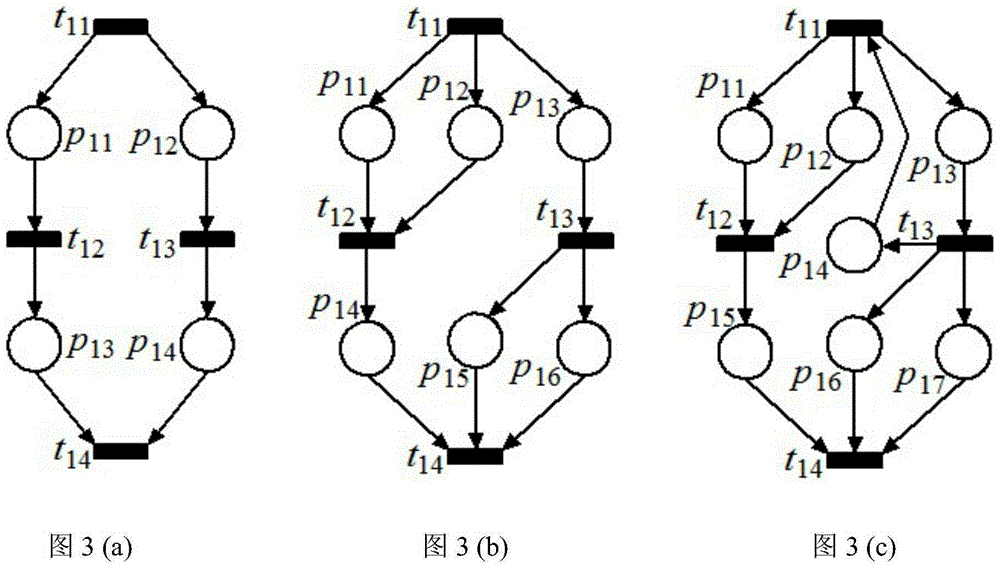

[0034] The core idea of the present invention is to treat the sign map module and other parts in the AESM differently, more specifically, to treat the key storehouse entity and the key storehouse differently. From the point of view of understanding, the essence of the method can be described as follows: First, the sign map module is virtualized as a place, because the sign map module in AESM itself can be regarded as a place replaced by a place. At this time, the network structure is a typical S 4 R, the key repository is the repository that uses the most or the least resources in each proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com