A distributed control method for automated manufacturing systems with assembly operations

An automatic manufacturing system, distributed control technology, applied in general control systems, control/regulation systems, program control, etc., to avoid exhaustive state space, reduce traffic, and ensure no deadlock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

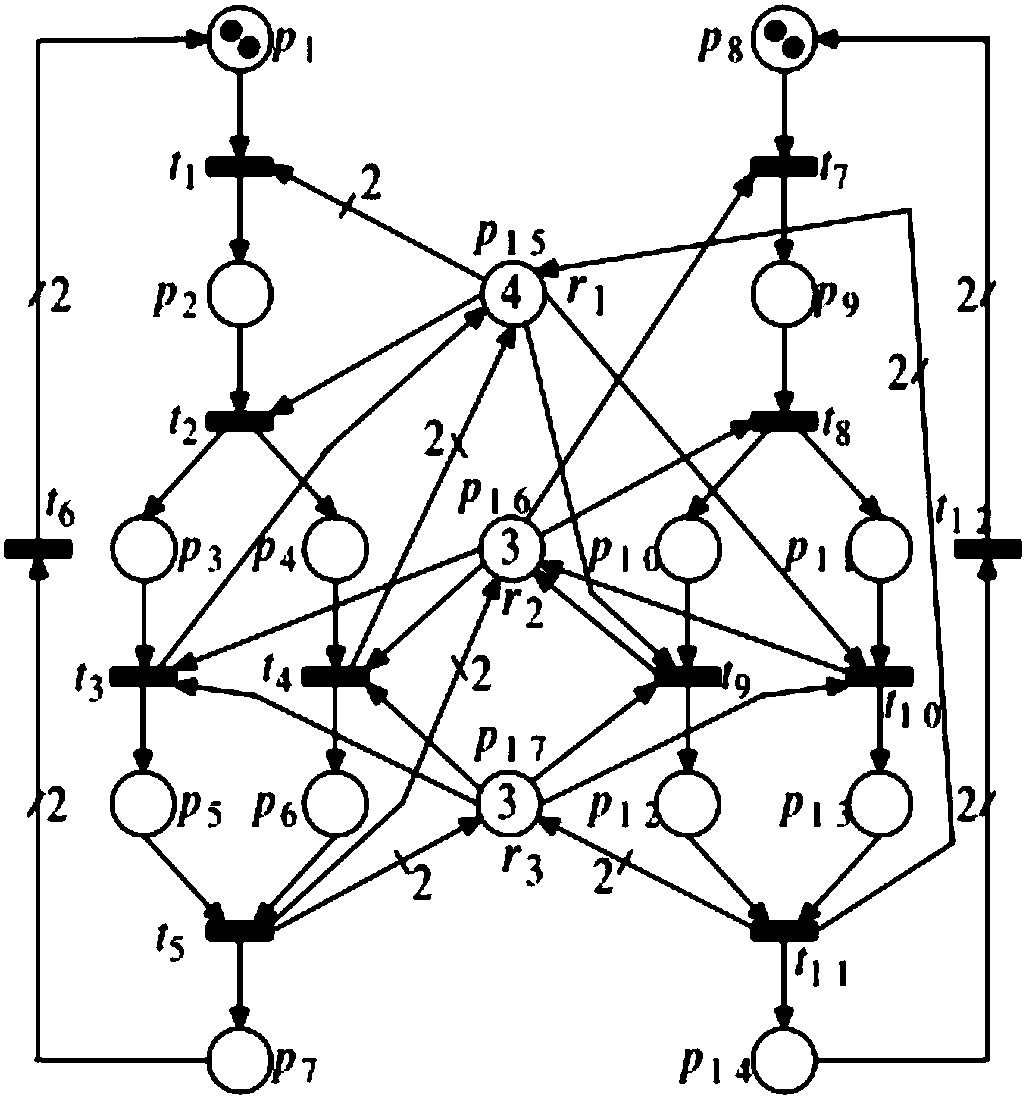

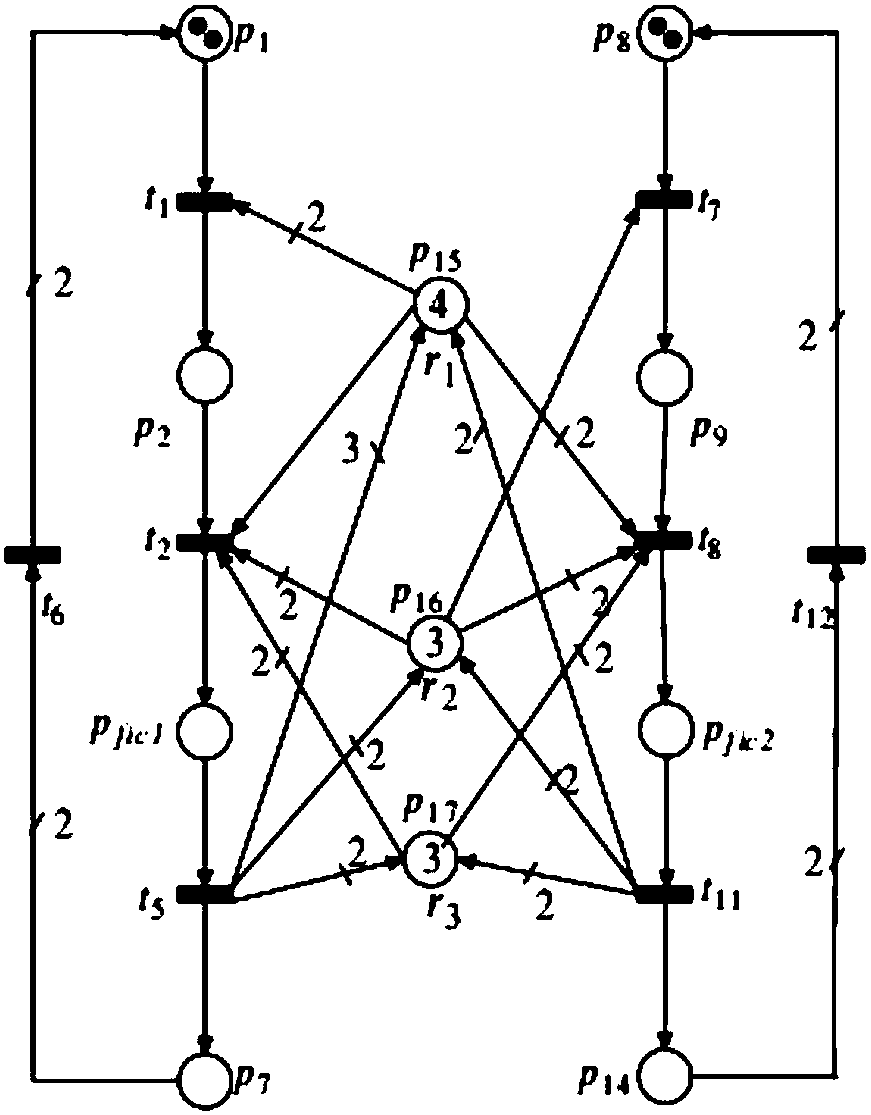

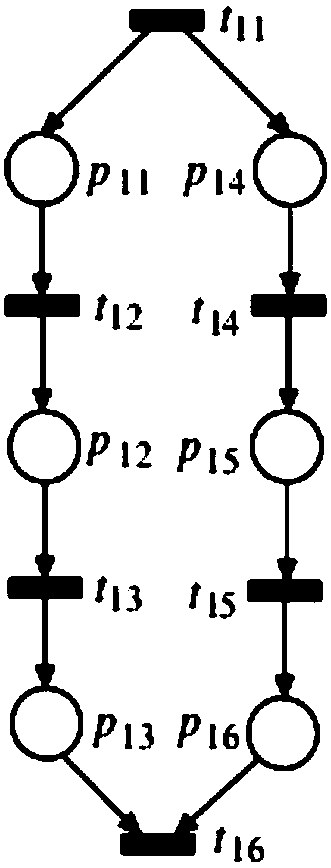

[0033] In the present invention, a distributed control method is proposed based on the automation system with assembly operation, and the dynamic search method is used to realize active distributed control online. Each process between the shunting operation and the assembly operation in the present invention is called a parallel process.

[0034] Firstly, the places in F-AMG are divided into key places and ordinary places. According to the definition of key places in the paper "DistributedSupervisor Synthesis for Automated Manufacturing Systems Using Petri Nets", if the various work stages of a process are executed sequentially, then the present invention will use the work stage with the smallest or greatest demand for resources Defined as a key place. In F-AMG, the various working stages are not completely connected sequentially. As mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com