Clamping device for forming machine

A clamping device and forming machine technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as complicated, slow forging and stamping speed, multiple manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

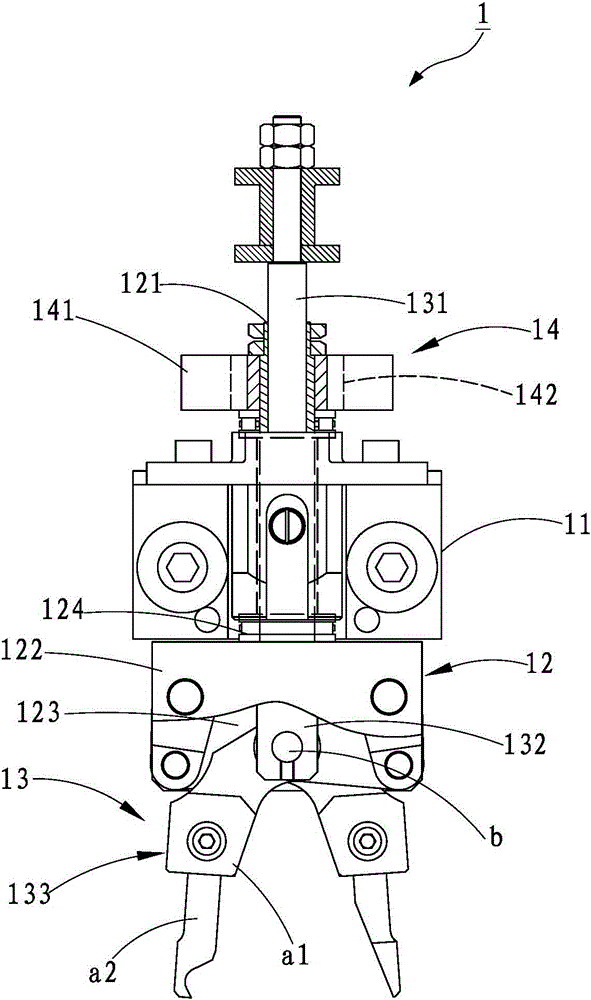

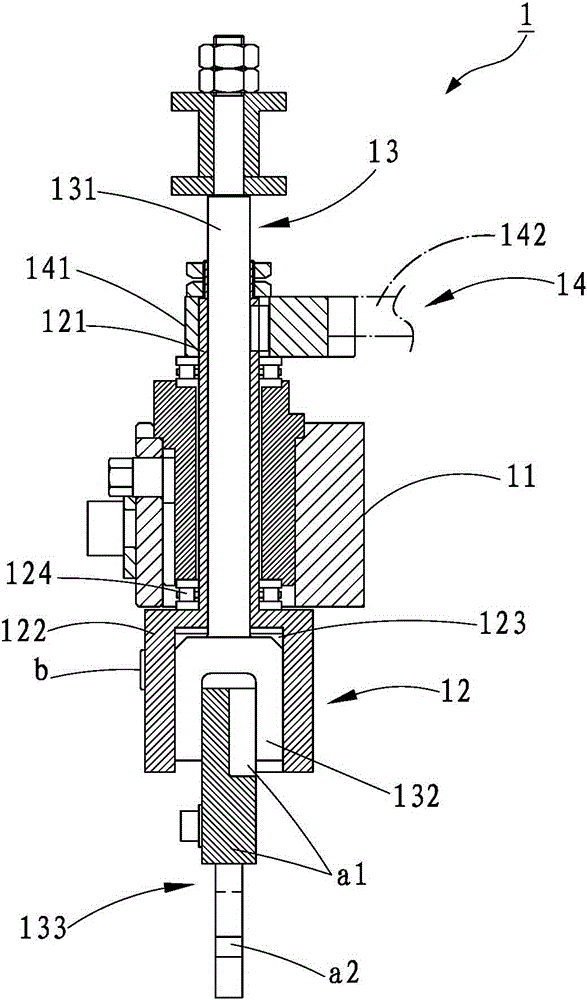

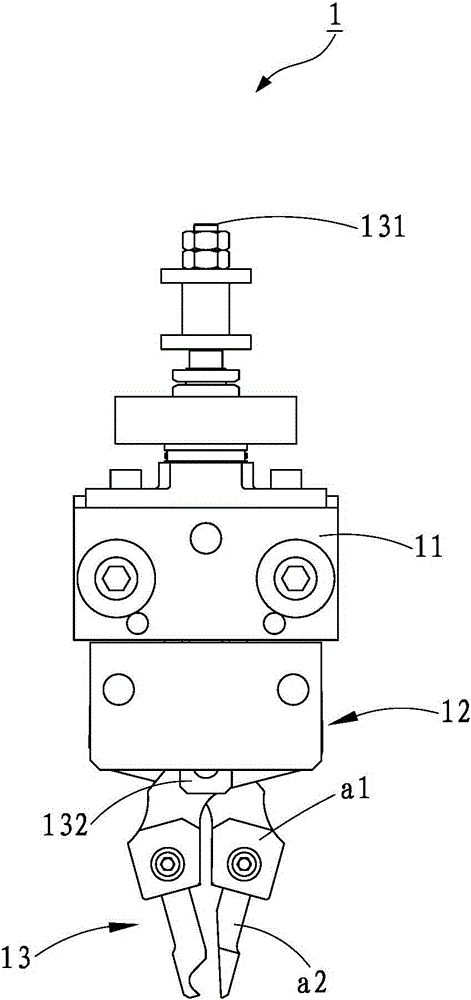

[0028] refer to figure 1 , figure 2 , a preferred embodiment of the clamping device 1 of the forming machine of the present invention, the clamping device 1 is arranged on a forging forming machine, and can be displaced between the forming die and the punching die of the forming machine (not shown in the figure), The clamping device 1 includes a base body 11, a rotating group 12 mounted on the base body 11, a clamping group 13 arranged under the base body 11, and a transmission group 14 that drives the rotating group 12 to rotate. ; Wherein, the rotating group 12 has a hollow sleeve 121 pivotally arranged on the seat body 11, and a rotating seat 122 fixed with the hollow sleeve 121, and the aforementioned rotating seat 122 forms an accommodating space inside 123, and the accommodating space 123 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com