Mechanical disc brake device

A mechanical, disc brake technology, applied in the field of cable-pulling mechanical disc brake devices, can solve the problems of difficult maintenance, high cost of disc brakes, and inconvenient installation in the later period, and achieve the effects of convenient later maintenance, low cost, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

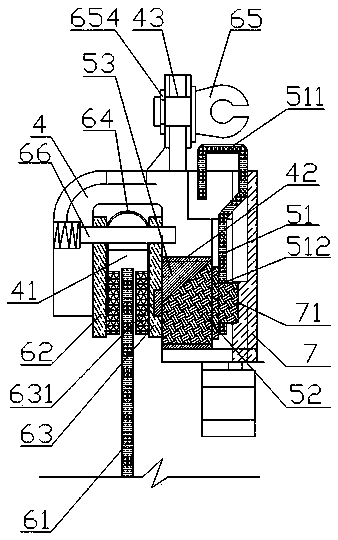

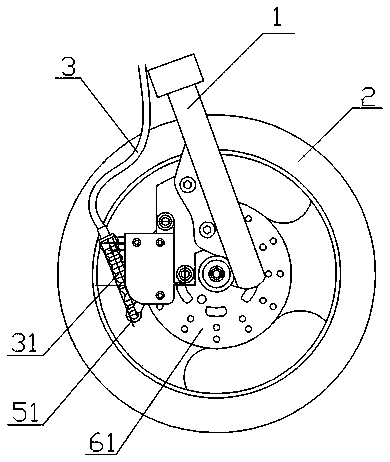

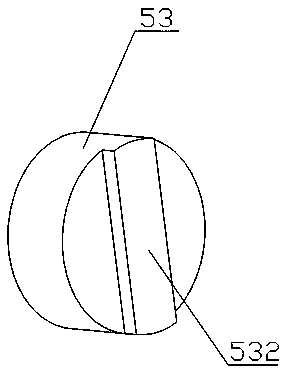

[0021] like figure 1 and figure 2 As shown, a mechanical disc brake device is installed on one side of the shock-absorbing frame 1, and the hub 2 is installed in the middle of the shock-absorbing frame 1. The brake force mechanism, the brake transmission mechanism, and the brake actuator. The housing 4 is provided with a chamber 41 for accommodating the brake actuator. The brake actuator includes a disc brake disc 61, a first brake pad 62, a second The brake pad 63, the return piece 64 and the brake pad fixing piece 66, the first brake pad 62 and the second brake pad 63 are placed in the chamber 41 through the brake pad fixing piece 66, and are close to the chamber through the return piece On the two side walls of 41, the disc brake disc 61 is placed between the two brake pads, the casing 4 is provided with a through groove 42 perpendicular to the disc br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com