A super large floating structure

A floating structure and super-large technology, which is applied in the field of offshore floating platforms and super-large floating structures, can solve the problems of poor impact resistance and shock absorption effect, achieve vibration attenuation, ensure continuity, and suppress back and forth swings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

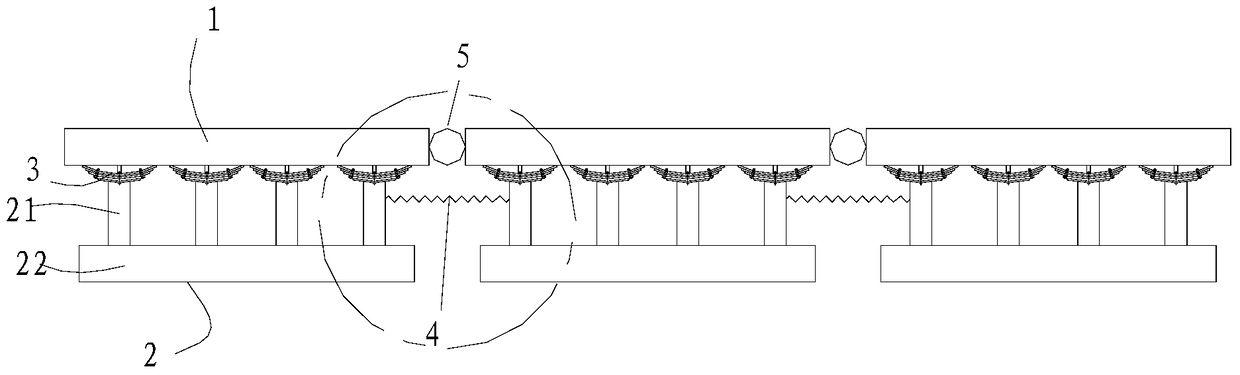

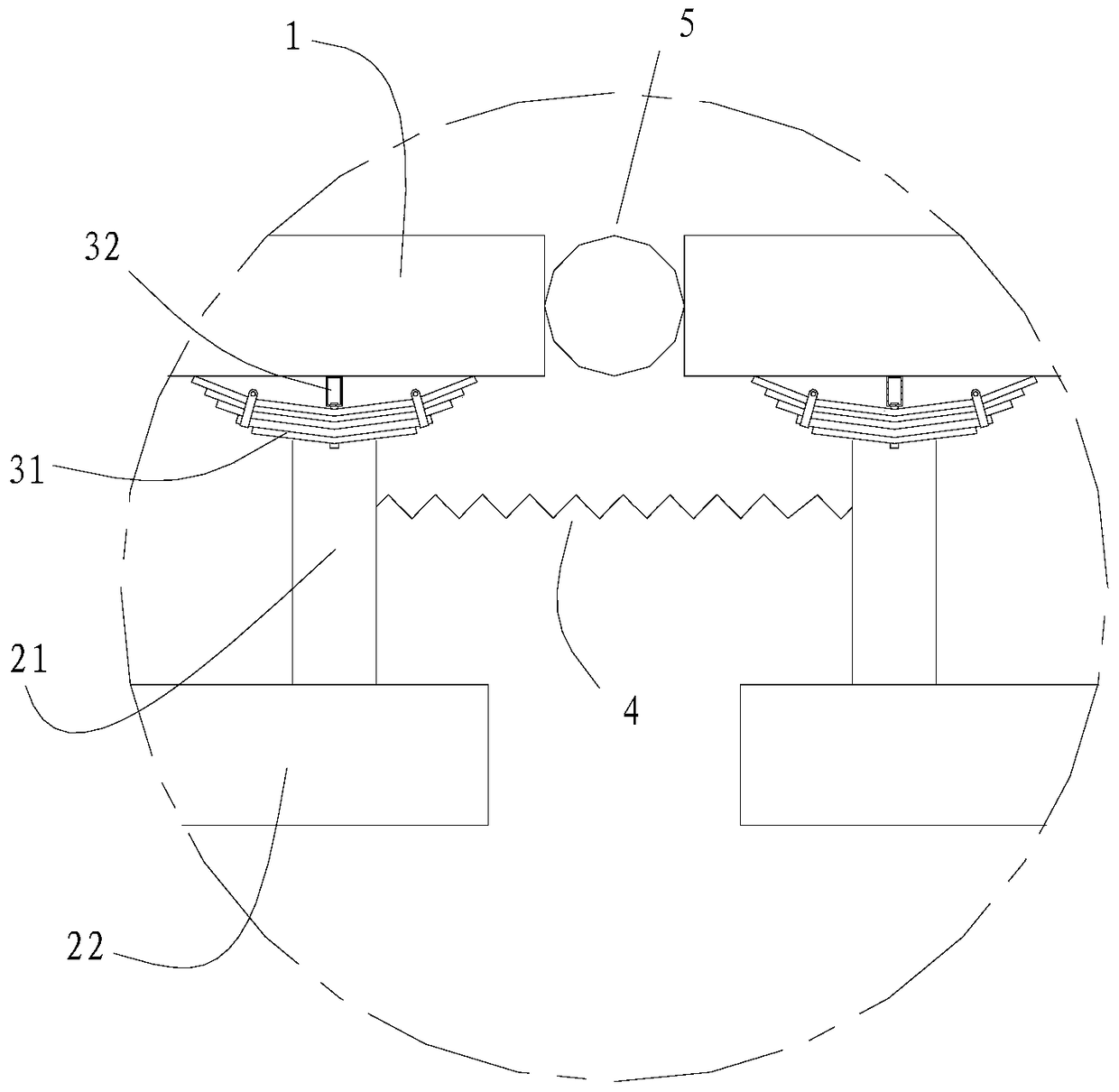

[0033] Such as Figure 1-2 As shown, a super large floating structure includes several connected modules. Each module includes an upper deck 1, a lower floating body 2 and a suspension system 3, and the suspension system 3 is arranged on the upper deck 1 and the lower floating body 2. between.

[0034] Two adjacent modules are connected by a flexible connecting piece. The flexible connecting piece in this embodiment includes an elastic piece 4 and a hinged piece 5. The hinged piece 5 is arranged between two adjacent upper decks 1, and the lower floating body 2 includes uprights 21 and The lower floating body 22 and the elastic member 4 are arranged between the uprights 21 of two adjacent lower floating bodies 2. The arrangement of the elastic member 4 and the hinge member 5 can ensure the continuity between the modules in the super large floating structure, and at the same time ensure that it has good impact resistance and shock absorption effects, and the structure is simple, th...

Embodiment 2

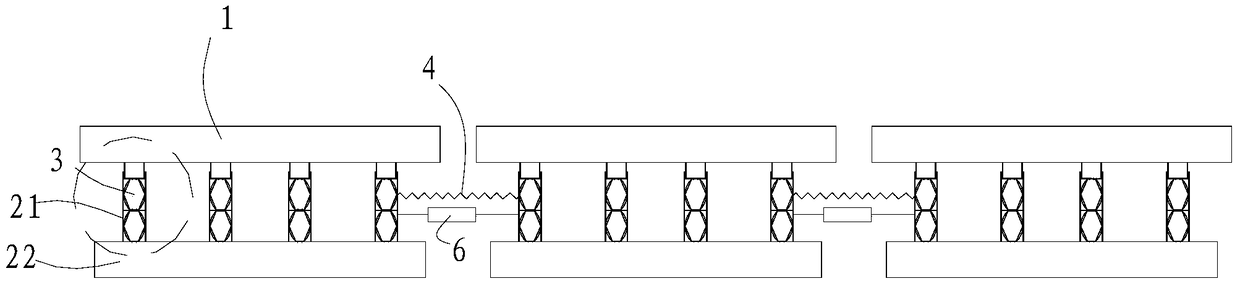

[0037] Such as Figure 3-5 As shown, the flexible connecting member in this embodiment includes an elastic member 4 and a first damper 6, and both the elastic member 4 and the first damper 6 are arranged between the uprights 21 of two adjacent lower floating bodies 2. The arrangement of the elastic member 4 and the first damper 6 can ensure the continuity between the modules in the super-large floating structure, while ensuring that it has good impact resistance and shock absorption effects, and has a simple structure and superior connection performance. Easy to implement.

[0038] In addition, the lower floating body 2 in this embodiment includes a lower floating body main body 22 and a hollow column 21 provided at the upper end of the lower floating body main body 22. In the column 21, first compartments 212 separated by bulkheads 211 are sequentially formed from top to bottom. And the second cabin 213, the suspension system 3 in this embodiment is specifically: the suspension...

Embodiment 3

[0042] Such as Image 6 As shown, the difference from Embodiment 1 is that in this embodiment, there is no flexible connection between the modules, and two adjacent upper decks 1 are connected to a lower floating body 2 through two suspension systems 3. Each upper deck 1 can be connected to the lower floating body 2 through two suspension systems 3, without additional connecting parts, simple and stable structure, cost saving, and good impact resistance and shock absorption effects.

[0043] The other structures in this embodiment are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com