A clip-on aero-engine main mounting joint mechanism

A technology of aero-engine and clamping mechanism, which is applied in the construction of power plants, etc., can solve the problems of low installation efficiency of aero-engines, achieve the effects of reducing assembly labor intensity, good practicability, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

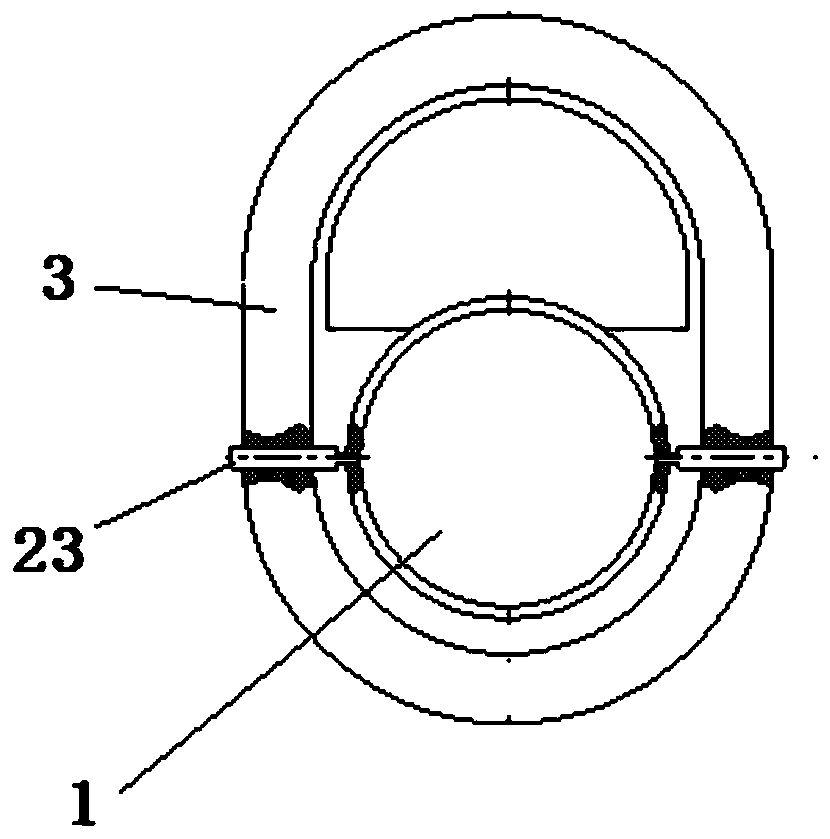

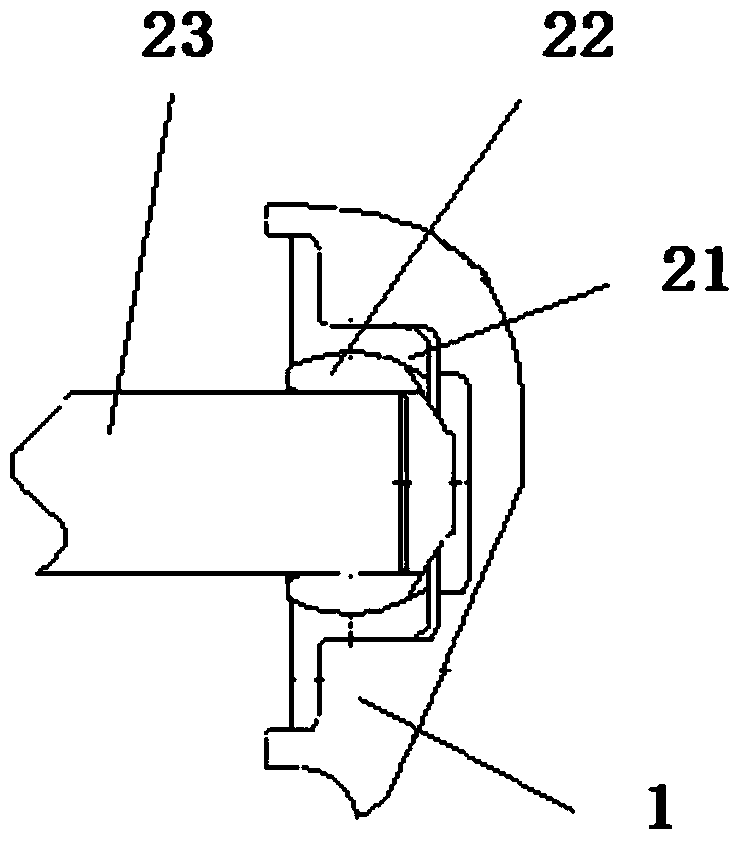

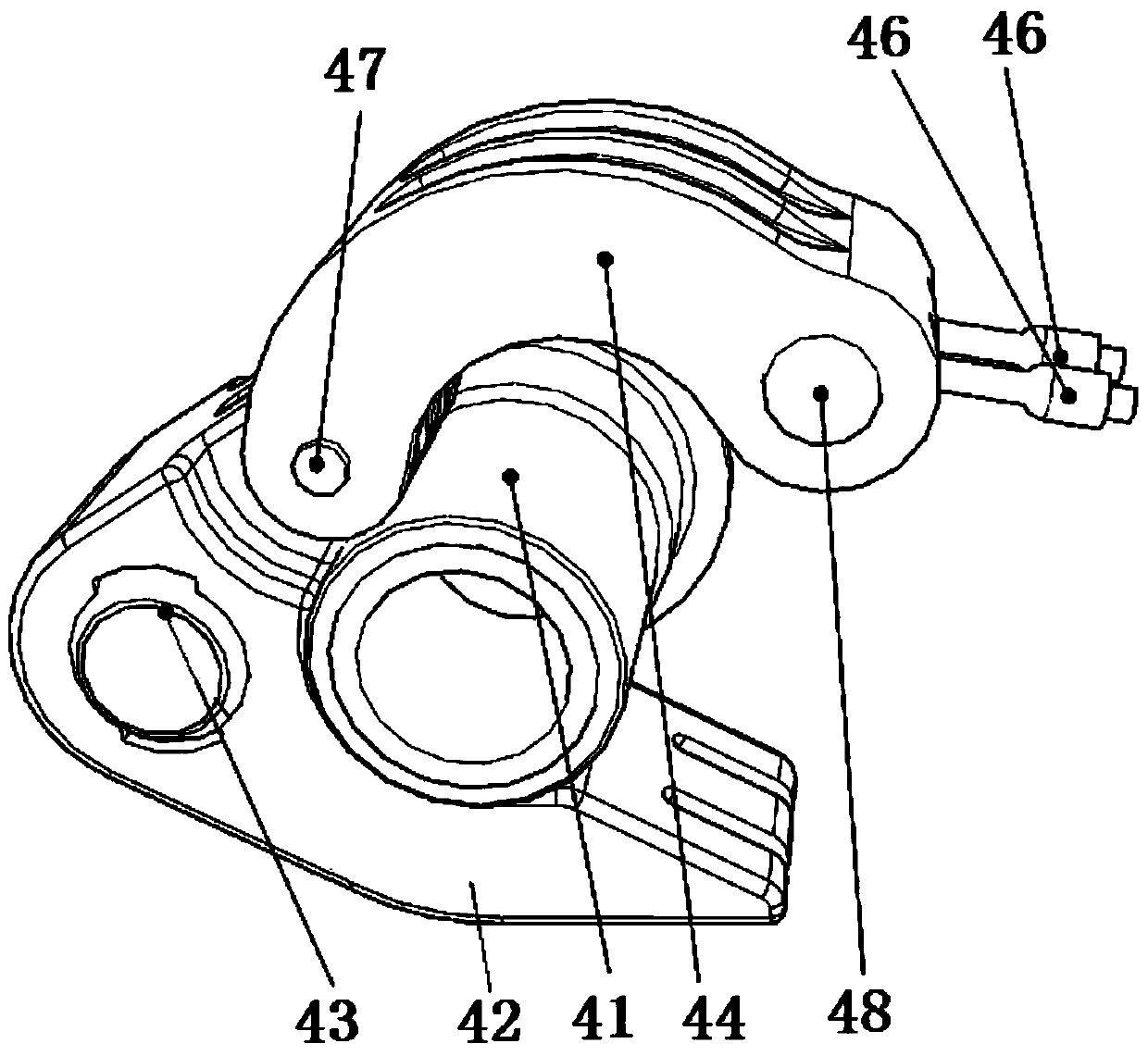

[0039] Especially as image 3 As shown, the clamping mechanism includes a mounting section lower cover 42 and a mounting section upper cover 44 .

[0040] The lower cover 42 of the installation section is bent, and one end ( image 3 middle left end) is provided with a through hole, and the installation joint ball head 43 is movably arranged in the through hole (its internal shape is similar to the ball seat of the prior art), so that the installation joint ball head (43) has a predetermined amount ( Determined by the mounting joint ball head 43 and the through-hole structure) for omni-directional rotation compensation; and, one end of the mounting joint ball head 43 near the engine 1 ( image 3 middle left end) is fixedly connected with the main bearing ring 3 of the aircraft; an end near the engine 1 of the ball joint 43 can be fixedly provided with a shaft (not shown), and is fixedly connected with the main bearing ring 3 of the aircraft by the shaft.

[0041] The mountin...

Embodiment 2

[0044] Especially as Figure 4 As shown, the clamping mechanism also includes a mounting section lower cover 42 and a mounting section upper cover 44 .

[0045] The lower cover 42 of the installation section is bent, and one end ( Figure 4 The left end in the middle) is provided with a through hole, and the fixed pin 45 is fixedly arranged in the through hole, and one end of the fixed pin 45 near the engine 1 is fixedly connected with the main bearing ring (3) of the aircraft.

[0046] The mounting section loam cake 44 is bent shape equally, and one end ( Figure 4 The left end in the center) is hinged on the end with the fixed pin 45 of the lower cover 42 of the installation section through the first rotating shaft 47.

[0047] One end of the thrust pin 41 close to the engine 1 is fixedly connected with the installation joint ball 43, and the installation joint ball 43 is movably installed in the installation joint ball seat of the engine 1 (the installation joint ball seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com