Filament bundle conveying paired wheel device

A technology of filament tow and tow, which is applied in the field of wheel-to-wheel device for smooth and fast conveying of polyacrylonitrile low-K value filament tow, which can solve tow disturbance, winding accident, restrict the smooth running of filament and the development of filament production capacity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

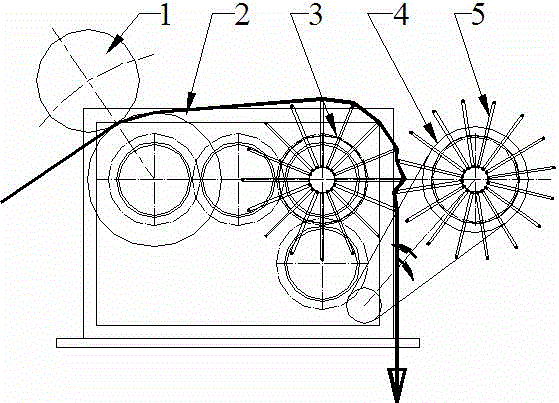

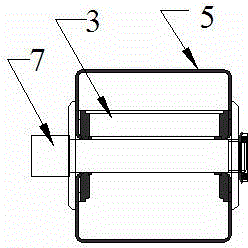

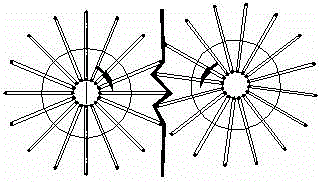

[0018] A long tow conveying counter-wheel device, comprising a beading wheel 1, a tow conveying counter-wheel device 2 is connected to the rear of the beading wheel 1, and the tow transporting counter-wheel device 2 includes two mated counter-wheels Wheel one 3 and opposite wheel two 4, described opposite wheel one 3 is arranged on the rear portion of rubberized wheel 1 and the position is fixed, described opposite wheel two 4 is arranged on the rear portion of opposite wheel one 3, and described opposite wheel two 4 is connected There is a cylinder 6, and the cylinder push rod on the cylinder 6 realizes that the second wheel 4 approaches or moves away from the first wheel. Teeth, the wire wheel teeth of the first wheel 3 and the second whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com