Patents

Literature

30results about How to "There will be no entanglement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

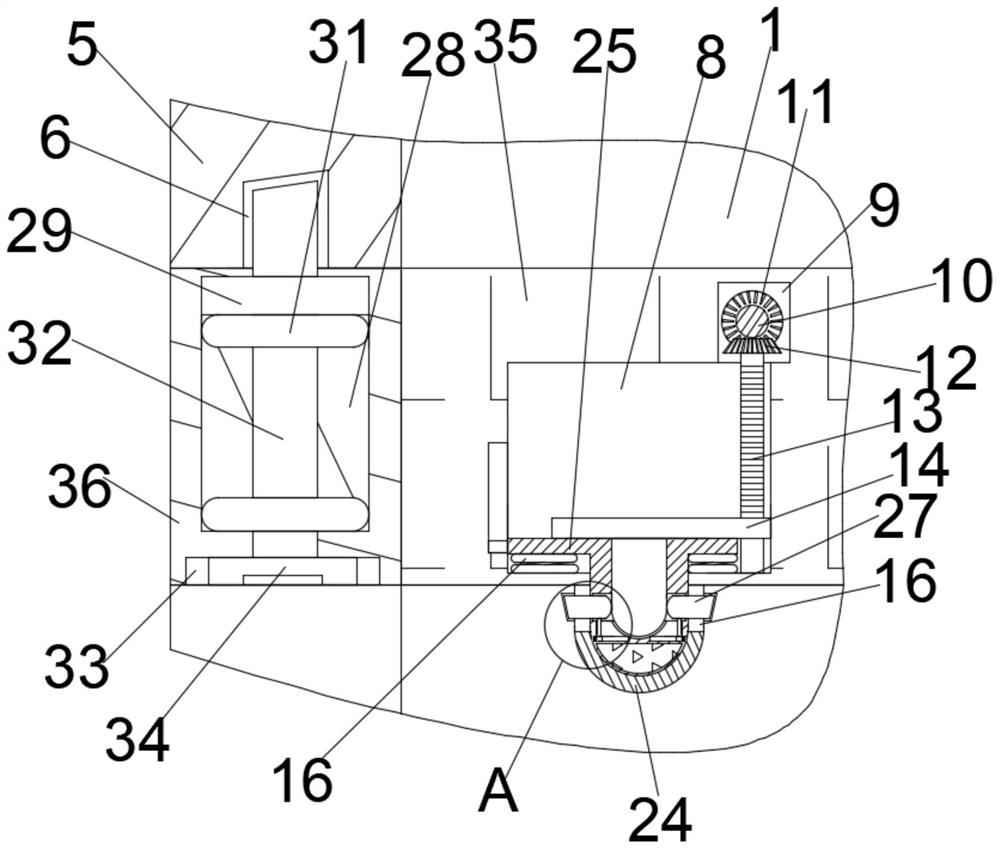

Textile fabric processing device with humidity adjusting function

InactiveCN108085890AThere will be no entanglementEasy to cleanLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingGear driveEngineering

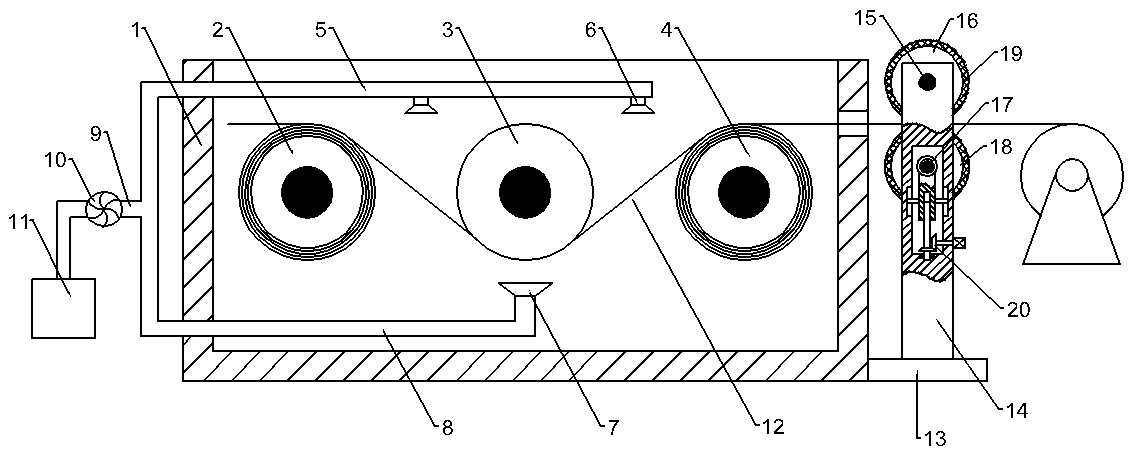

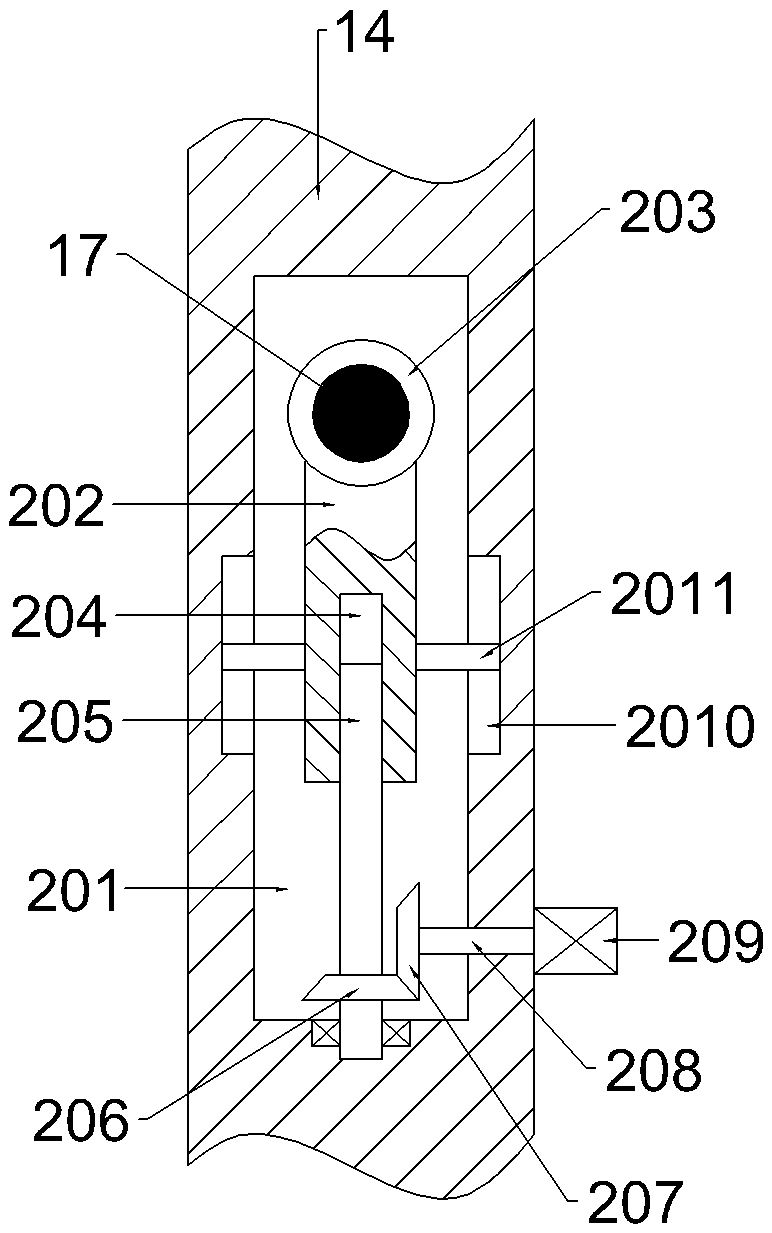

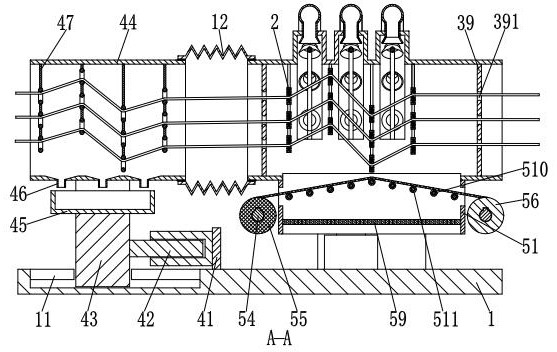

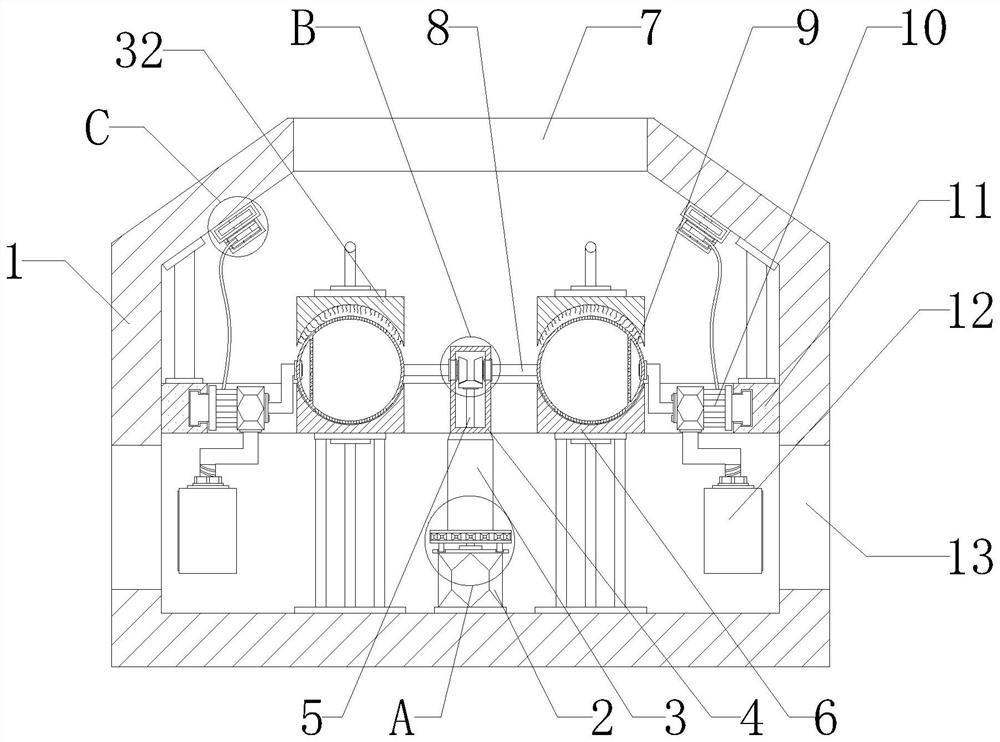

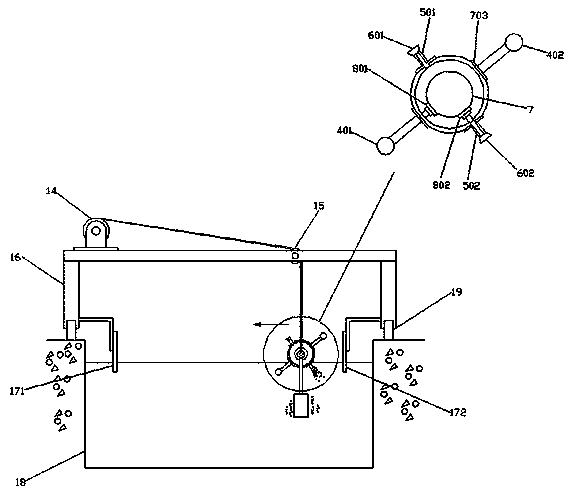

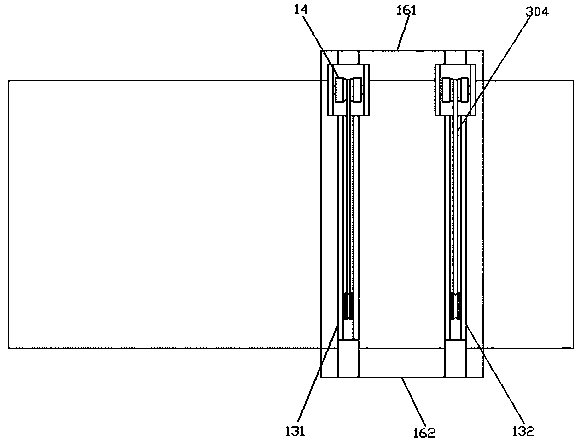

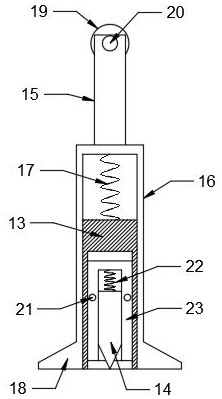

The invention discloses a textile fabric processing device with humidity adjusting function, which comprises a processing slot; the processing slot is orderly provided with a first collecting roller,a guide roller and a second collecting roller from left to right; a textile cloth orderly crosses through the first collecting roller, the guide roller and the second collecting roller; the upper partof the processing slot is provided with a first water spray pipe, and two first nozzles are arranged on the first water spray pipe; the inner bottom part of the processing slot is provided with a second water spraying pipe, and a second nozzle is arranged on the second water spraying pipe. The textile fabric processing device has the beneficial effects of effectively improving the bleaching and cleaning rates; the rotary shaft drives an active bevel gear to rotate, an active conical gear drives a driven conical gear to rotate, and the driven conical gear drives a thread rod to rotate; an adjusting rod matched with the thread rod can drive a lower extruding wheel to upwards or downwards move; thus the extruding force is changed, and the water removal is controlled.

Owner:严梓展

Cable rotation type winding device

ActiveCN110615319AEasy to cleanAvoid gatheringFilament handlingCleaning using toolsConductor CoilElectric cables

Owner:永新县宏展电线电缆有限公司

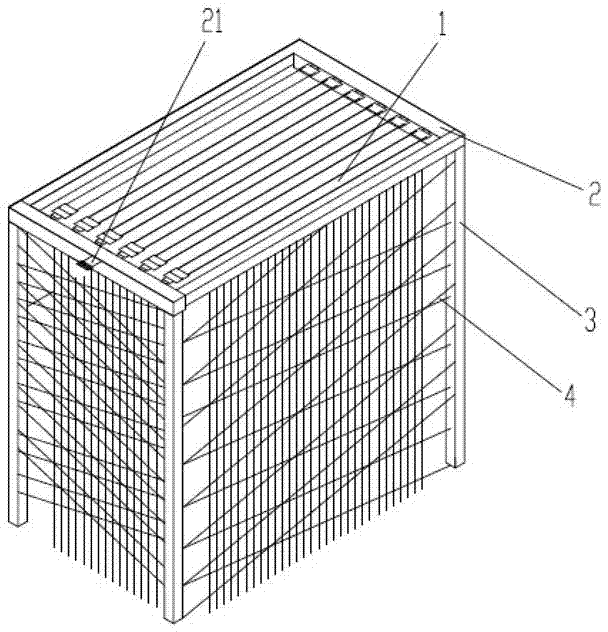

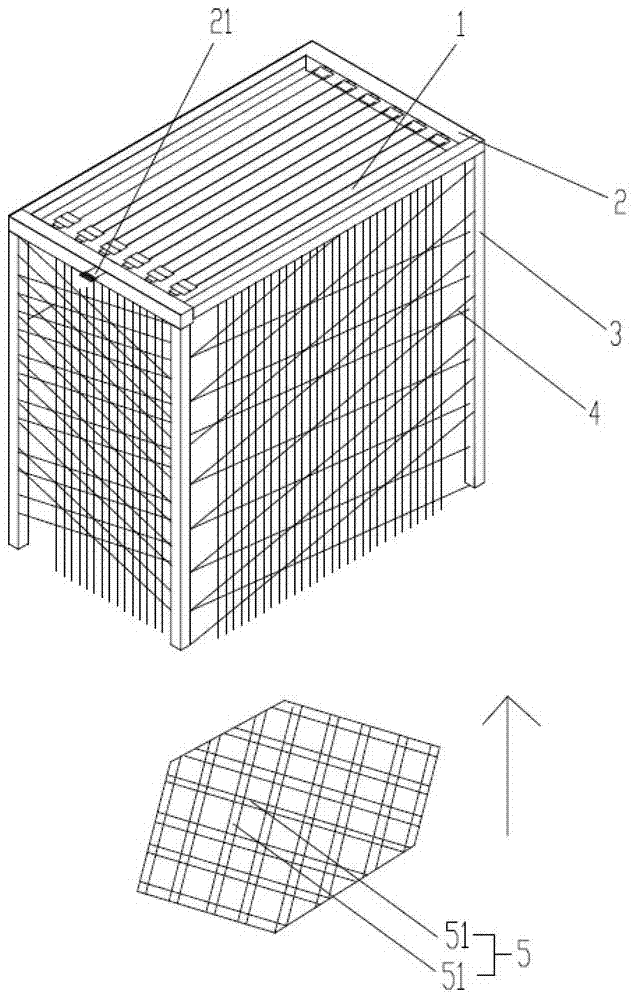

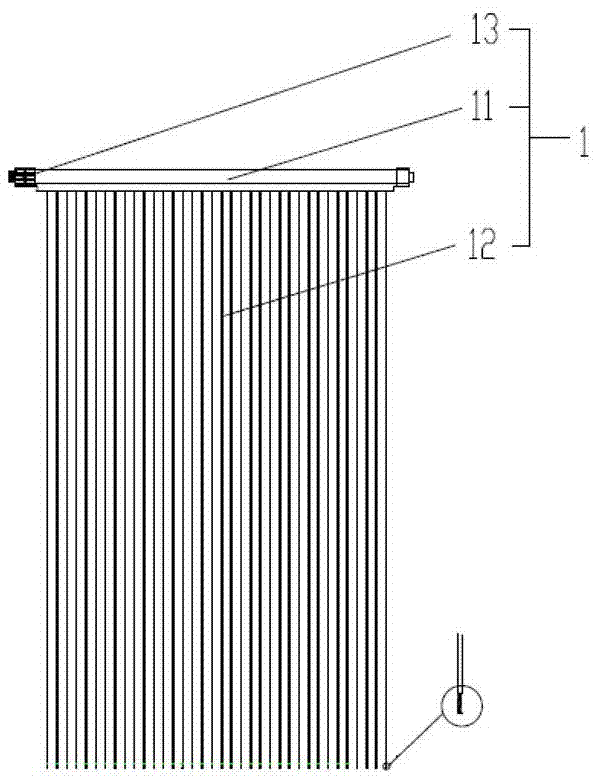

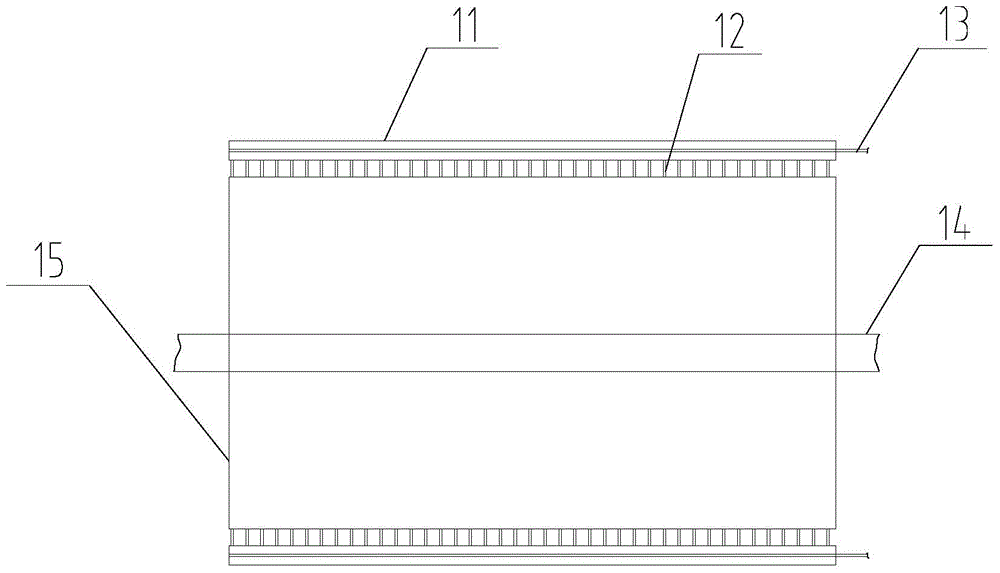

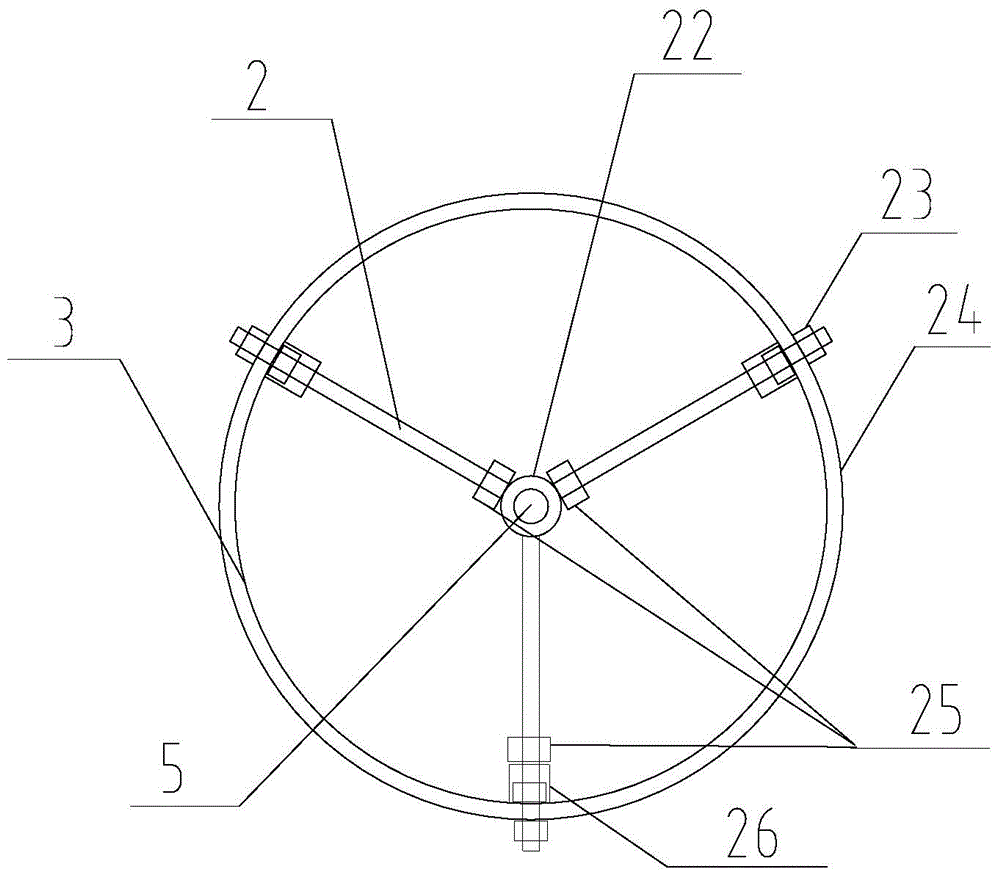

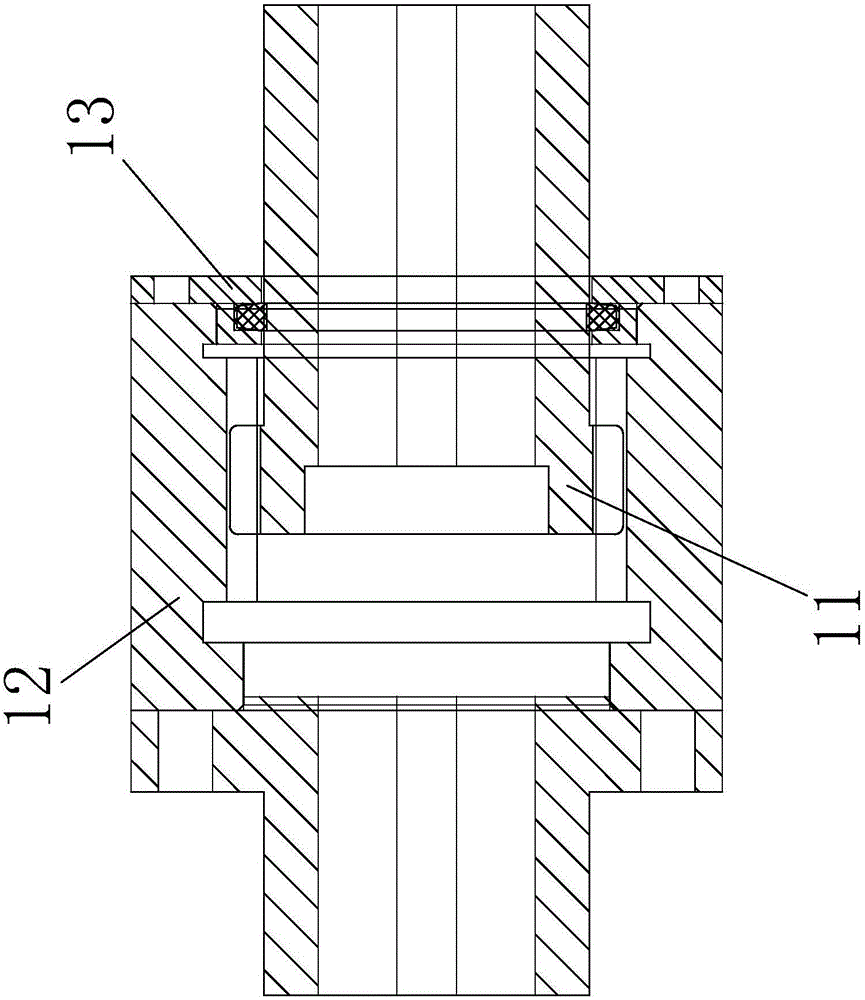

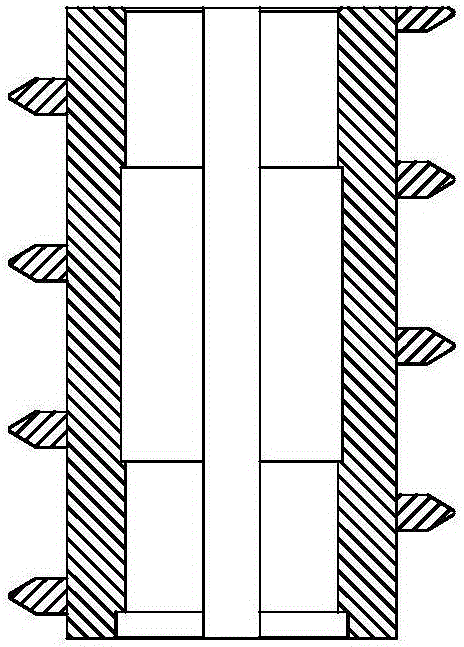

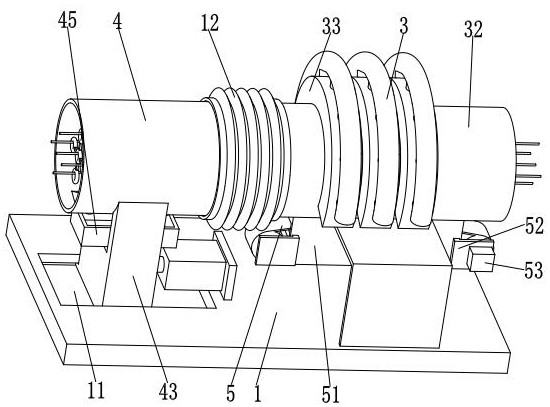

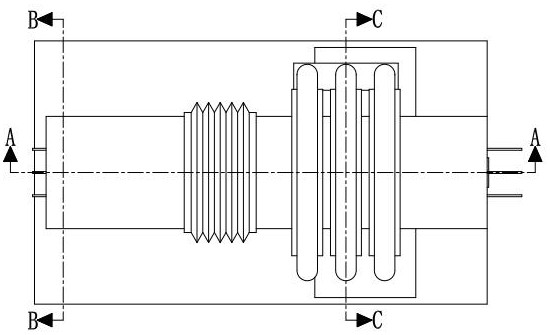

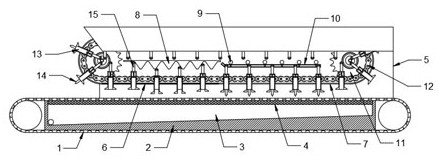

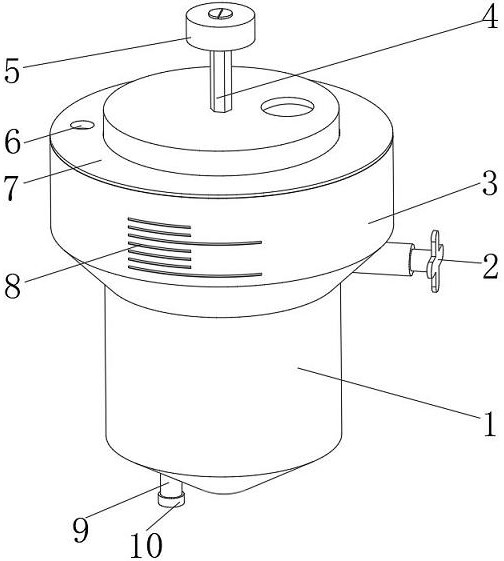

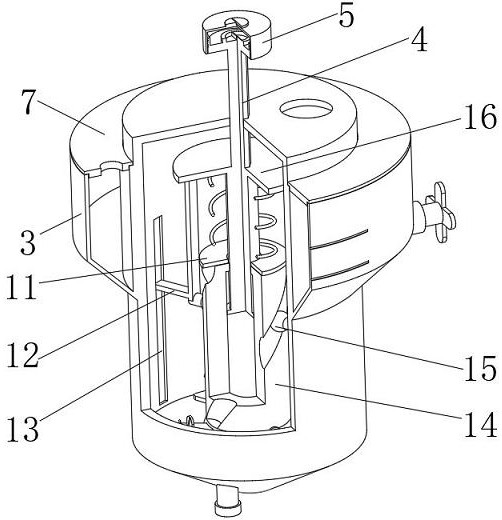

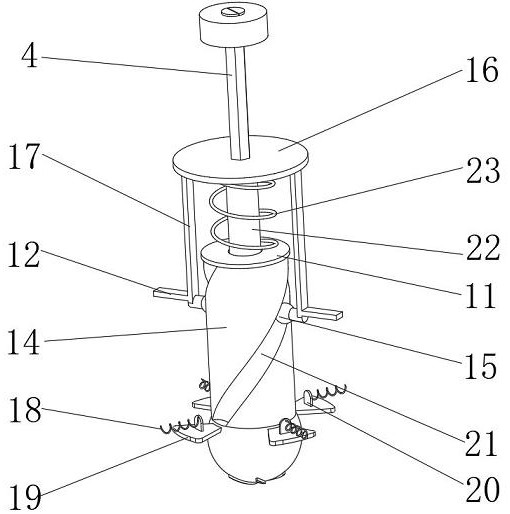

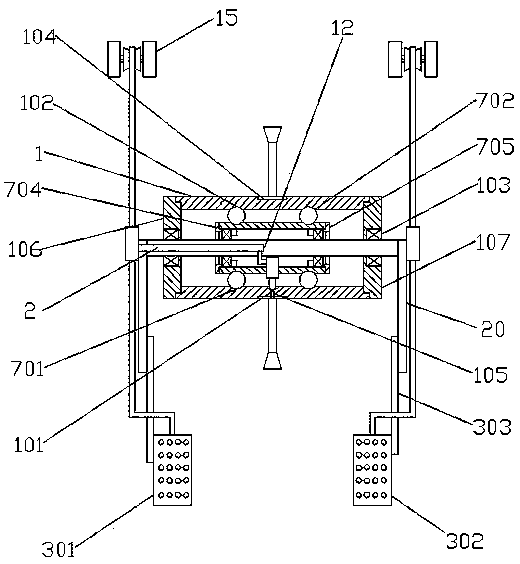

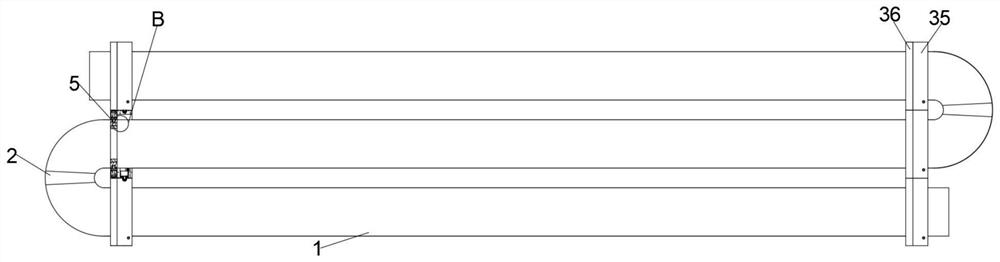

Anti-clogging hollow fiber immersed membrane component with high aeration efficiency

InactiveCN106881023AWon't cause shakingNo entanglementSemi-permeable membranesSustainable biological treatmentFiberHollow fibre membrane

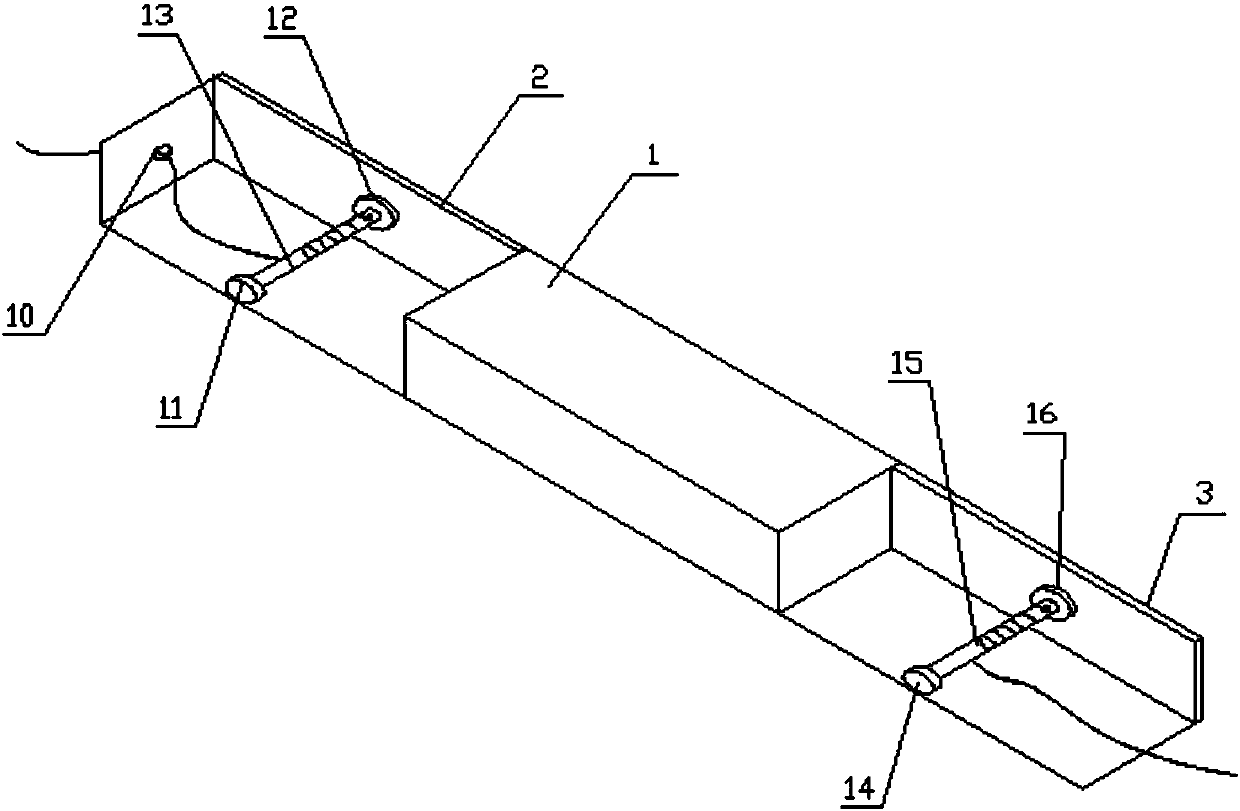

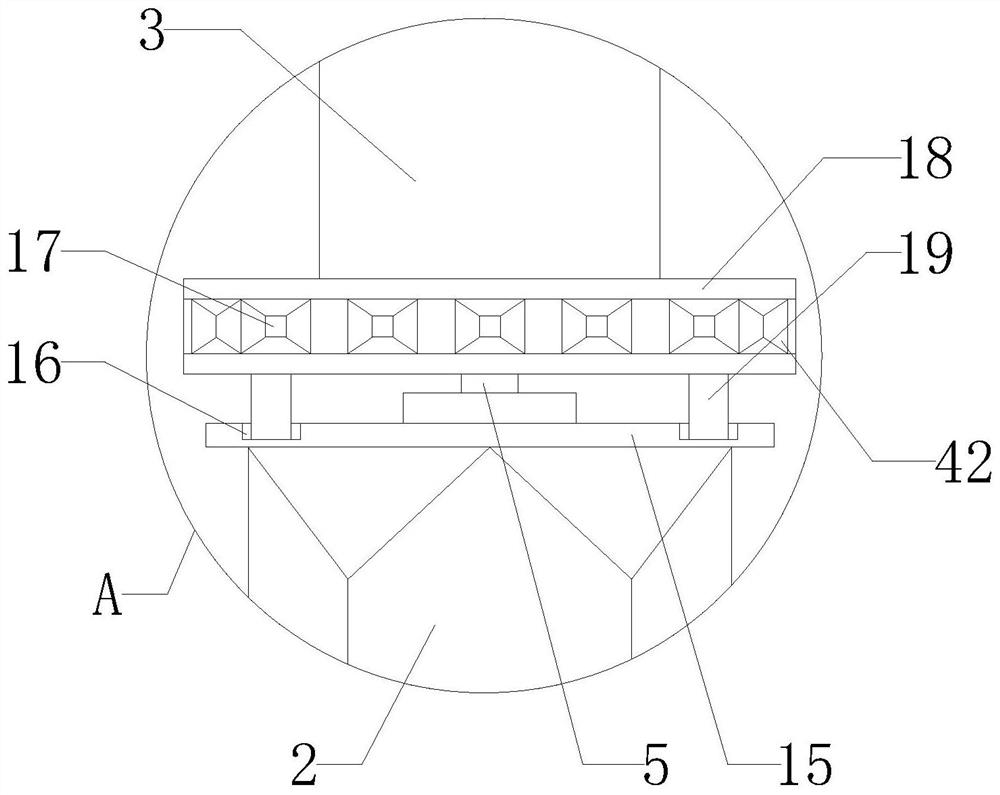

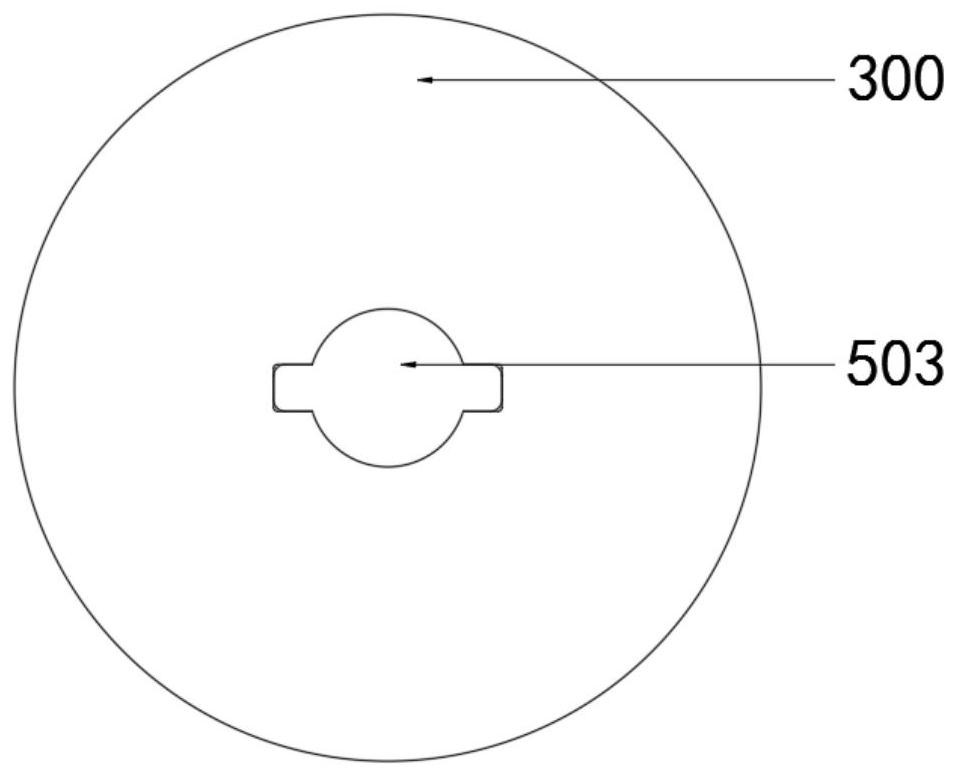

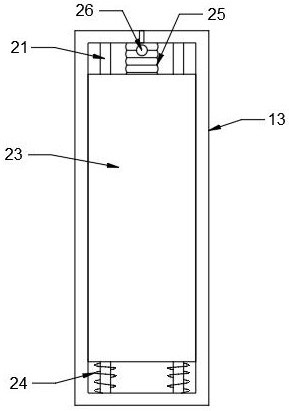

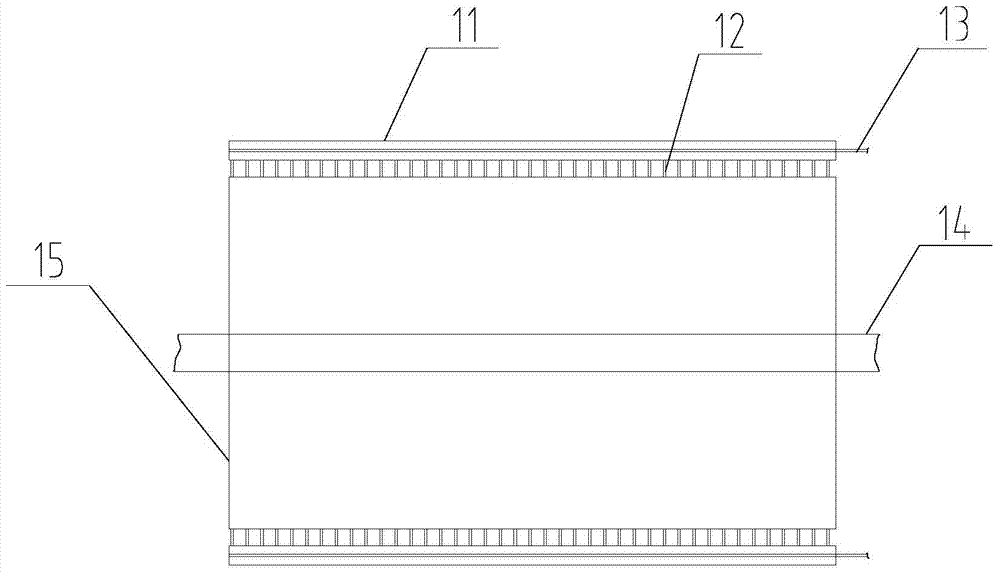

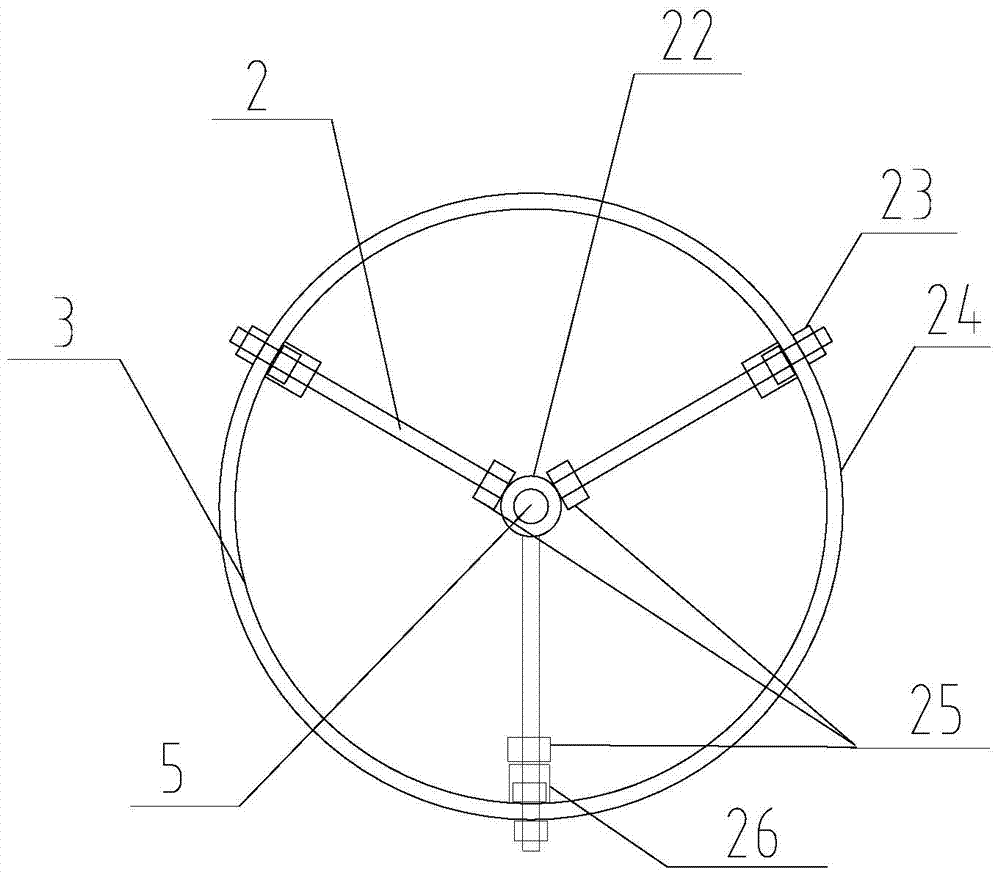

The invention relates to the technical field of sewage treatment, and particularly discloses an anti-clogging hollow fiber immersed membrane component with high aeration efficiency, which comprises a plurality of hollow fiber membrane components (1), a hollow membrane frame (2), a framework (3), an anti-winding screen mesh (4) and an aeration component (5), wherein each hollow fiber membrane component (1) comprises a hollow tube (11) and hollow fiber membrane filaments (12), one end of each hollow fiber membrane filament (12) is sealed, the other end of each hollow fiber membrane filament (11) is communicated with the corresponding hollow tube (11), internally threaded joints (13) are mounted on the hollow tubes (11), the hollow tubes (11) are communicated with the hollow membrane frame (2) through the internally threaded joints (13), a water outlet (21) is formed in the hollow membrane frame (2), the framework (3) is mounted on the hollow membrane frame (2), the anti-winding screen mesh (4) is mounted on the framework (3), and the aeration component (5) is mounted below the hollow membrane frame (2).

Owner:HANGZHOU KAIHONG MEMBRANE TECH

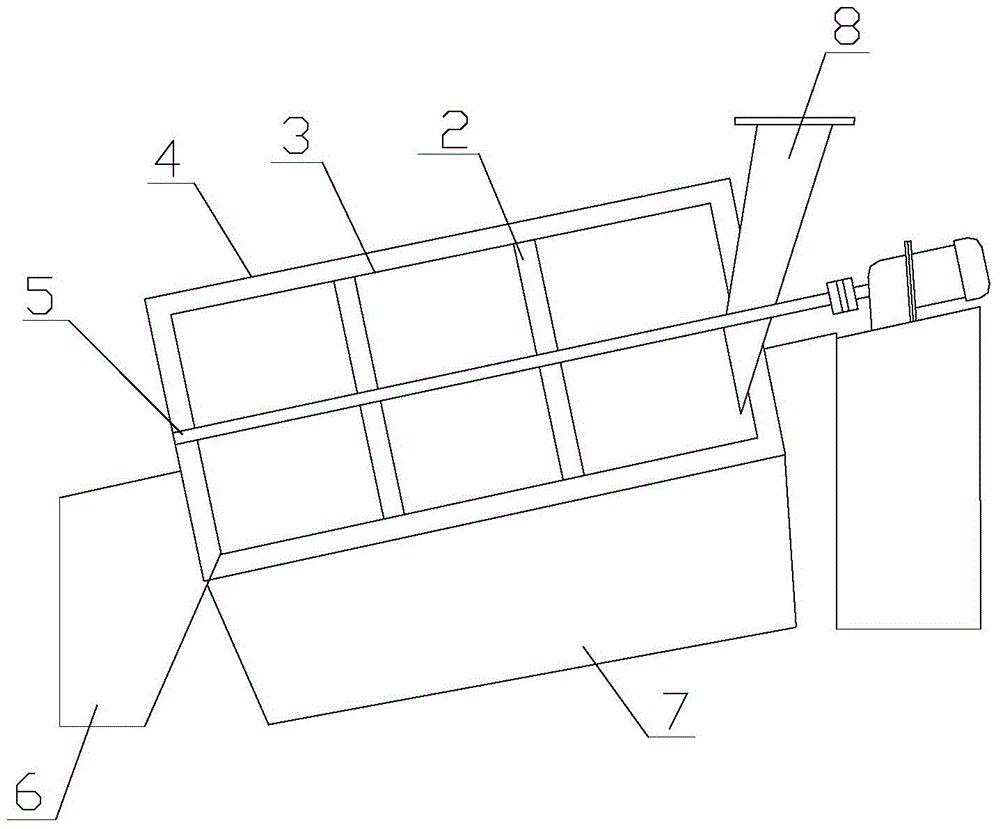

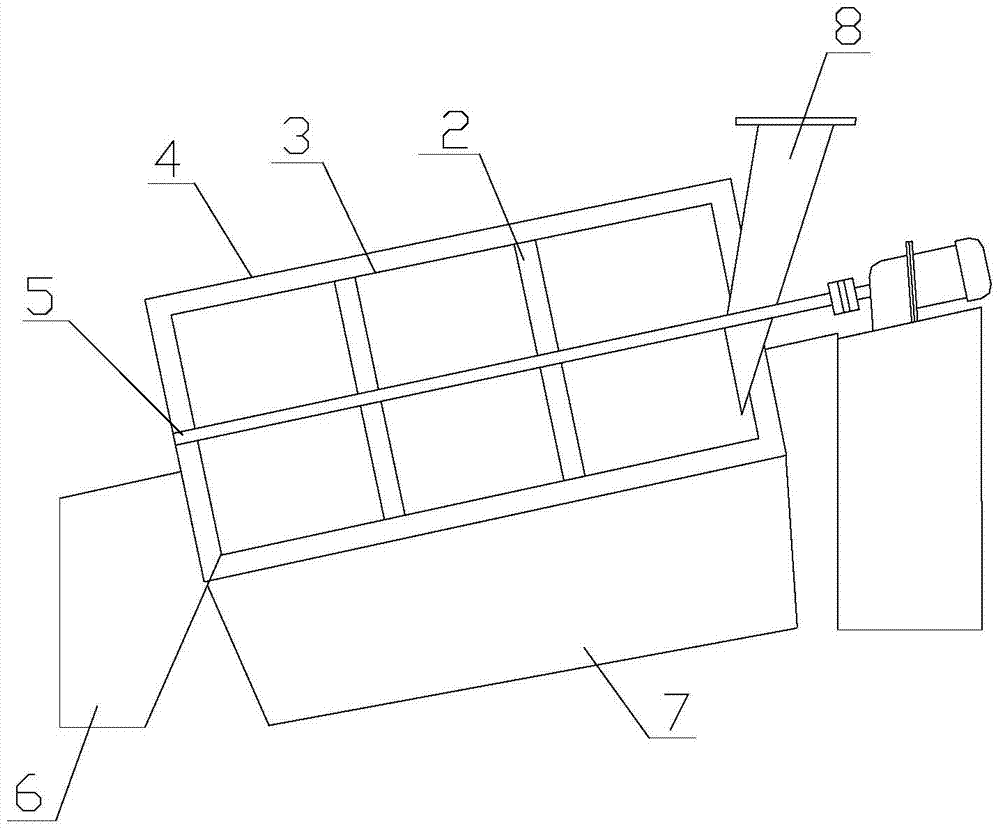

Anti-blocking rotary screen

The invention provides an anti-blocking rotary screen, and relates to the technical field of screening equipment, so as to solve the problem that the comb-type cleaning device of the existing anti-blocking rotary screen is bad in cleaning effect and easy to be damaged. The anti-blocking rotary screen comprises a rotationally installed cylindrical screen drum. A main shaft in parallel with the central axis of the screen drum is arranged inside the screen drum. The main shaft rotates in synchronization with the screen drum. A plurality of smooth shafts for connecting the main shaft with the screen drum is further arranged inside the screen drum. All the smooth shafts are sleeved with vibrating hammers which are able to slide freely. The anti-blocking rotary screen is simple in structure, reasonable in arrangement, convenient in installation, good in blockage cleaning effect, saves the time for cleaning the screen drum manually, avoids the occurrence of unnecessary human body and mechanical damages, and reduces labor intensity. The anti-blocking rotary screen can also screen materials whose water content is more than 15%. The anti-blocking rotary screen shortens the screening time, increases the production efficiency, and the anti-blocking rotary screen is stable in production operations, and can be used for years without maintenance.

Owner:沈阳科翔电力环保设备有限公司

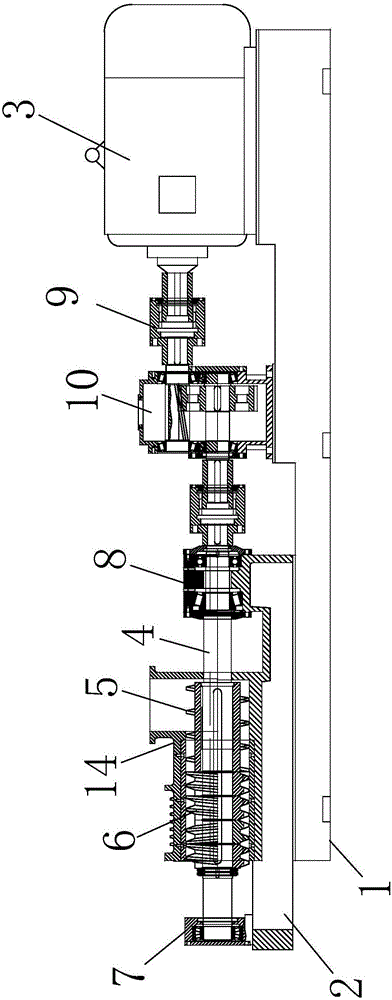

High-strength thread rolling machine

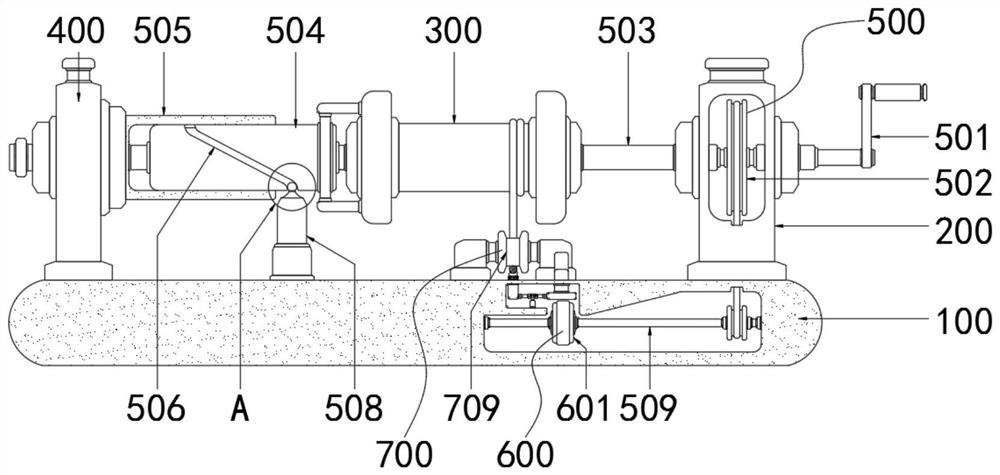

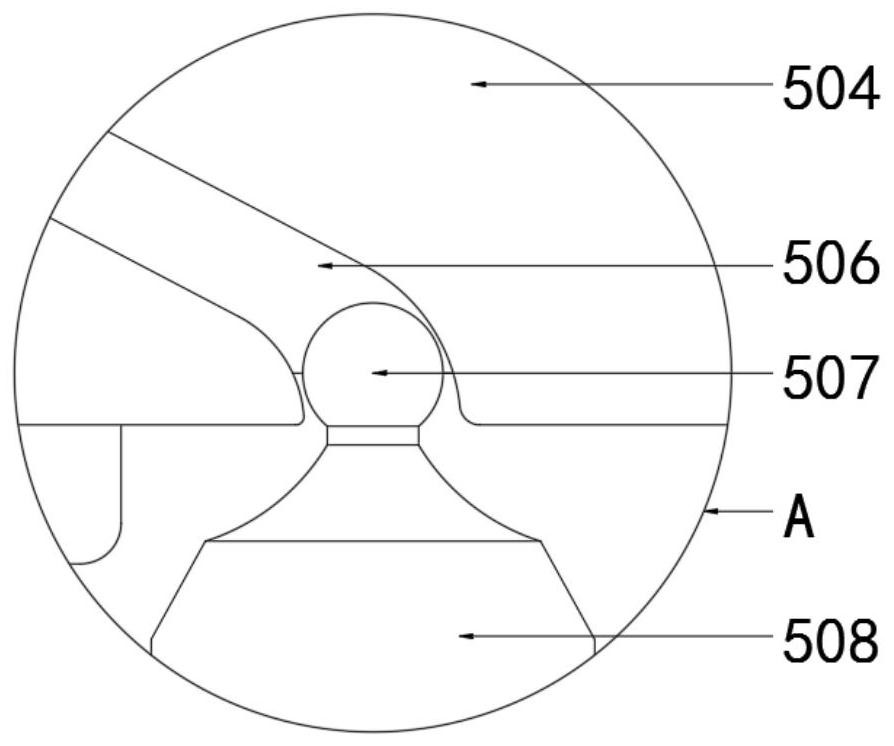

A high-strength thread rolling machine, including a base and a body, an organic body is installed at one end of the base, a drive motor is installed at the other end, two parallel plug-in rotating shafts are arranged inside the body, and the feeding of the plug-in rotating shafts Helical cutting blades with opposite helical directions are respectively arranged on the end parts, and knife rollers are respectively arranged on the discharge end parts of the plug-in rotating shaft, and the discharge end of the plug-in rotating shaft is fixed on the machine body through a detachable bearing seat, so The feed end of the plug-in rotating shaft runs through the bearing sleeve of the machine body and is rotatably connected with the gearbox through a gear coupling, and the driving motor is also rotatably connected with the gearbox through a gear coupling. The invention has low noise, the bearing is not easy to be damaged, and the phenomenon that the main shaft is not entangled by long fibers occurs.

Owner:ZHUCHENG ZENGYI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Textile yarn conduction drying equipment

ActiveCN114413605ADry thoroughlyIncrease the heating areaDrying gas arrangementsDrying machines with progressive movementsTextile yarnEngineering

The invention relates to the technical field of yarn drying, in particular to textile yarn conduction drying equipment which comprises a bearing plate, a guiding unit, a drying unit, a traction unit and a wool suction unit, the guiding unit and the drying unit are installed on the right side of the bearing plate, the traction unit is installed on the left side of the bearing plate, and the wool suction unit is installed at the lower end of the drying unit. According to the textile yarn drying device, the following problems existing in the textile yarn drying operation process can be solved: firstly, textile yarns are generally hung on a frame in a manual mode at present, then the textile yarns are dried by using a drying machine, and the textile yarns are not thoroughly dried due to the fact that the textile yarns are tightly attached to one another; moisture still remains on the yarn, and subsequent processing of the spinning yarn is affected. And 2, when a dryer dries the textile yarns, batting on the textile yarns is frequently blown up, and the batting drifts in the air, so that the working environment is influenced.

Owner:新沂久盛纺织科技有限公司

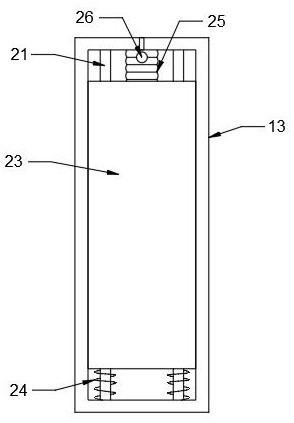

Power wire capable of being automatically stored

InactiveCN107611722AReduce the chance of breakageNo clutterFlexible lead accommodationTransformerEngineering

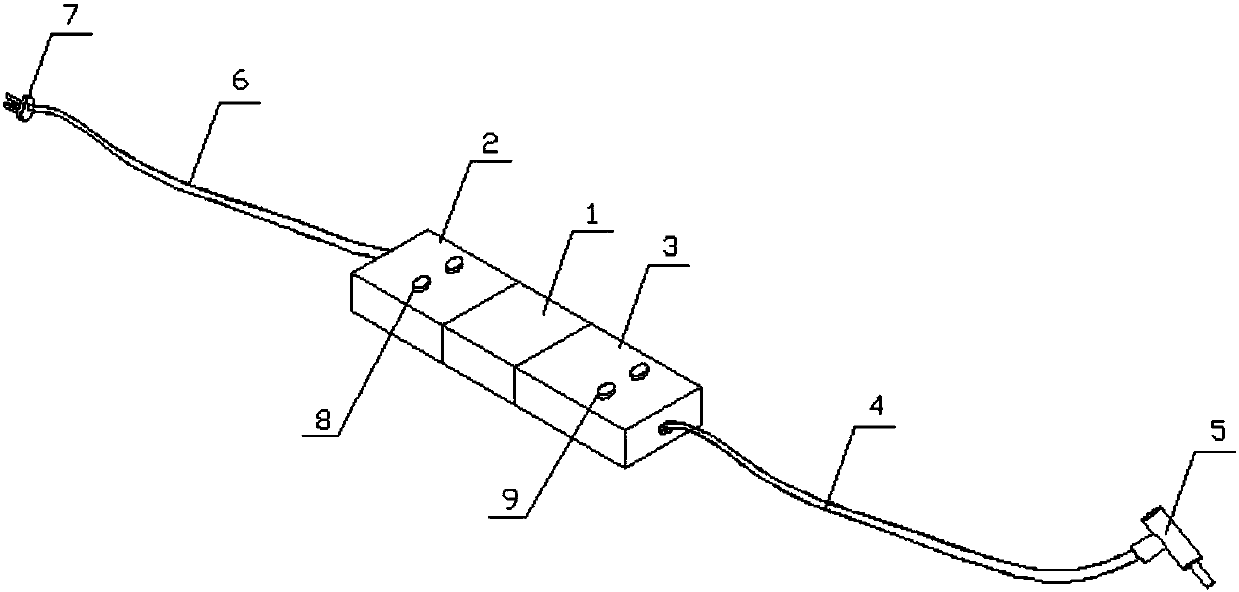

The invention discloses a power wire capable of being automatically stored. The power wire comprises a transformer, a first wire winding box and a second wire winding box. The first wire winding box is arranged on one side of the transformer. A first wire winding roller is arranged in the first wire winding box. One end of the first wire winding roller is provided with a first motor, and the otherend of the first wire winding roller is provided with a first connector. The first wire winding roller is provided with a first power supply wire. A three-hole plug is arranged at one end of the first power supply wire. The two ends of the first wire winding box and the two ends of the second wire winding box are respectively provided with power supply wire outlets. A first power switch button isarranged at the top end of the first wire winding box, and the second wire winding box is arranged on the other side of the transformer. A second wire winding roller is arranged inside the second wire winding box. A second motor is arranged at one end of the second wire winding roller. A second connector is arranged at the other end of the second wire winding roller. By means of the invention, the power wire can be folded and stored, and the damage probability of the power wire can be reduced. The winding phenomenon of a mouse wire is avoided. The phenomenon that a computer desktop is disordered is also avoided.

Owner:WUXI SHANGZHICHENG TECH CO LTD

High-efficiency digital printing ink raw material grinding device

ActiveCN113814035AGrind thoroughlyImprove grinding efficiencyCleaning using gasesGrain treatmentsEngineeringPrinting ink

The invention discloses a high-efficiency digital printing ink raw material grinding device, and particularly relates to the technical field of digital printing ink raw material grinding. The device is characterized in that a first motor and a second motor are respectively fixed on the front side and the rear side of the middle part of the bottom end in a grinding tank. The second motor drives a chain wheel on the rear side to rotate, the chain wheel can drive a chain wheel on the front side to rotate through a chain, in this way, the chain wheel on the front side can drive a rotating column to rotate, and the rotating column can drive a hollow grinding ball to roll in a grinding rail through a connecting shaft to conduct grinding work, and meanwhile, the first motor rotates a first bevel gear, in this way, the connecting shaft can be driven to rotate through a second bevel gear, the hollow grinding ball can be driven to rotate by the connecting shaft while rolling in the grinding rail, so that grinding is more thorough, the grinding efficiency is improved, and the problems that an existing digital printing ink raw material grinding device is poor in grinding efficiency due to the fact that raw materials are not ground thoroughly, and ground powder is inconvenient to collect, resulting in poor practicability are solved.

Owner:承德天成印刷科技股份有限公司

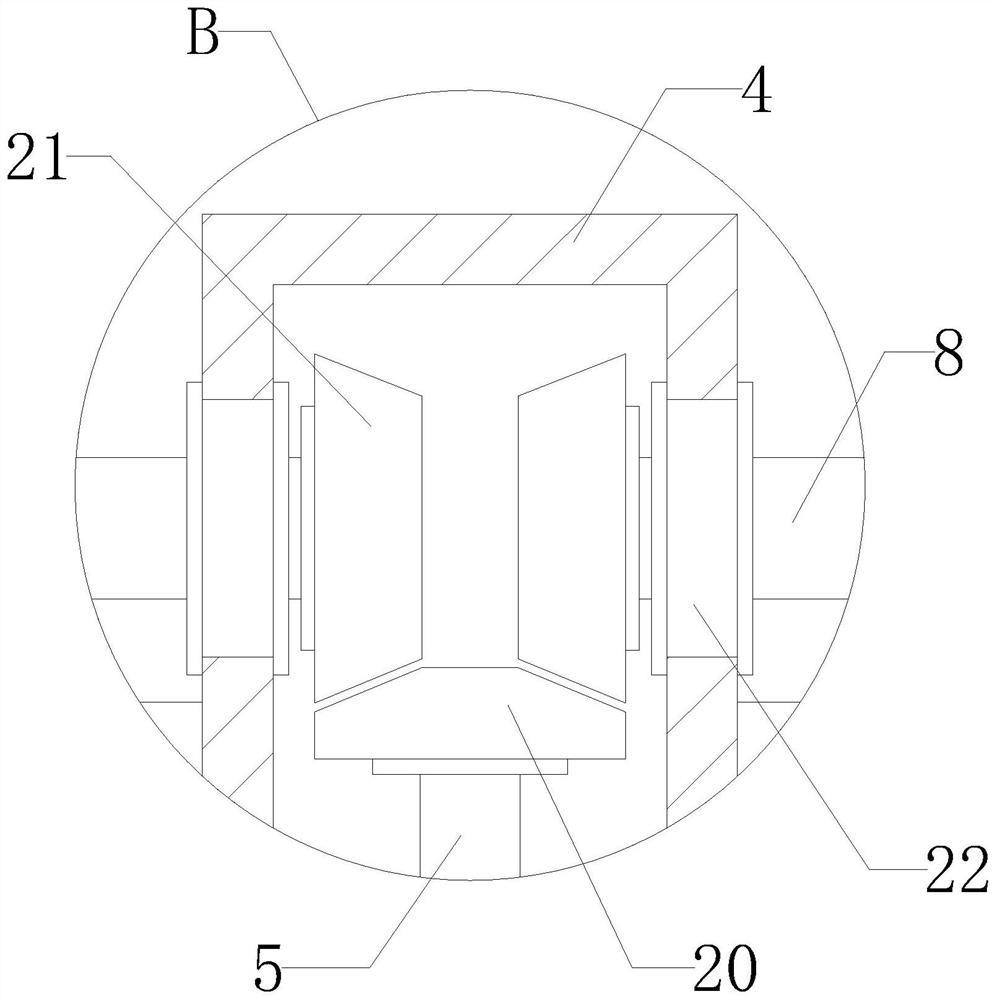

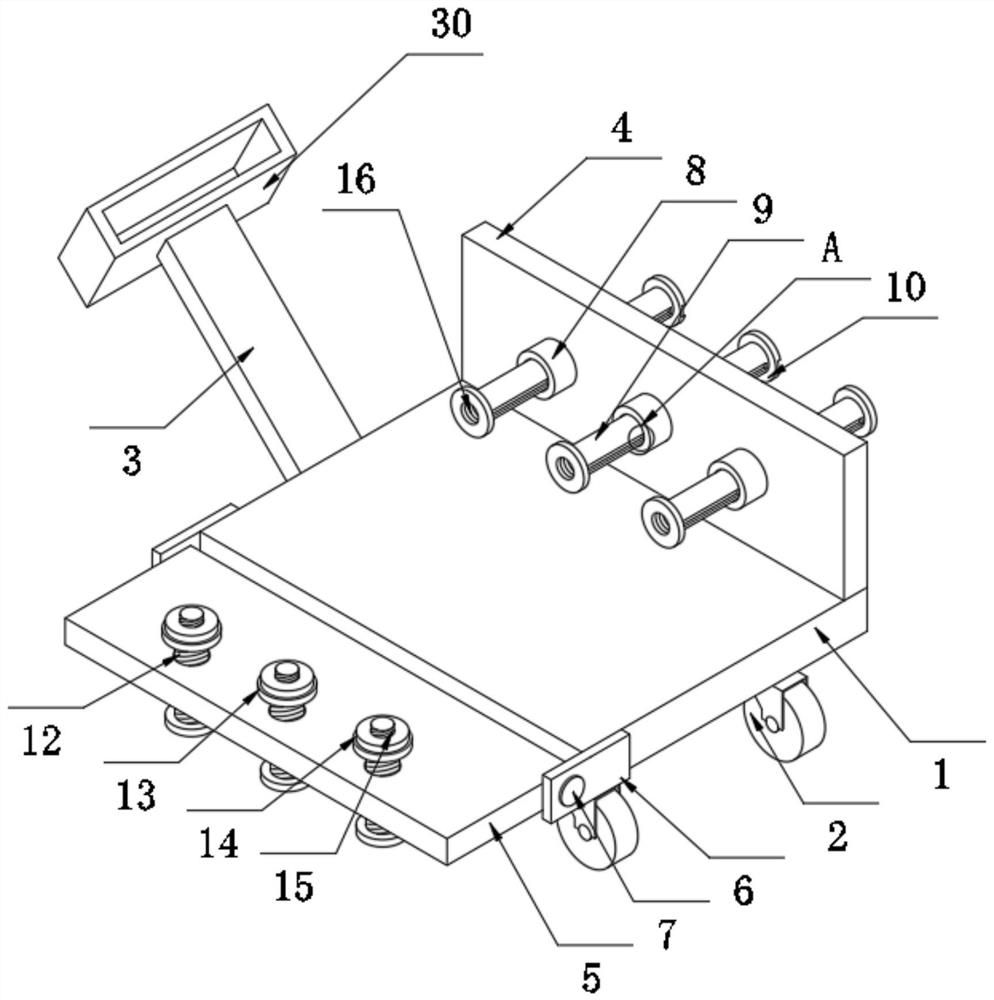

Textile bobbin conveying device and conveying method thereof

The invention discloses a textile bobbin conveying device and a conveying method thereof. The textile bobbin conveying device comprises a fixed bottom plate and pulleys, wherein the pulleys are fixedly installed on the sides of the lower surface of the fixed bottom plate, a fixed supporting plate is fixedly connected to one side of the upper surface of the fixed bottom plate, a movable supporting plate is arranged on one side of the fixed bottom plate, three fixed branch pipes are fixedly connected to one side of the middle of the fixed supporting plate, movable rods are arranged in the fixed branch pipes in a sleeved mode, a clamping mechanism is arranged on the other side of the middle of the fixed supporting plate, three external thread sleeves are connected to the top of the movable supporting plate in an equidistant threaded penetrating mode, and positioning mechanisms are arranged in the external thread sleeves. The textile bobbin conveying device has the beneficial effects that by means of the design of the fixed branch pipes and the clamping blocks, the multiple textile bobbins are connected to the fixed branch pipes at different positions in a sleeving mode before conveying, the movable supporting plate is rotated to drive the clamping blocks to be clamped into the other ports of the textile bobbins, and then fixing operation can be conducted from the two ends of the textile bobbins.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

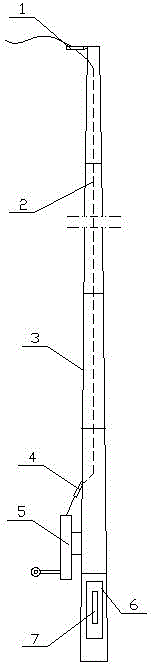

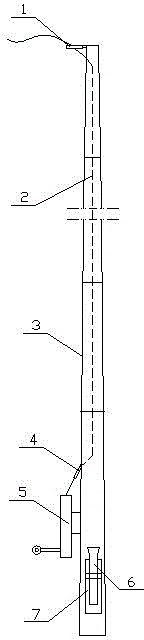

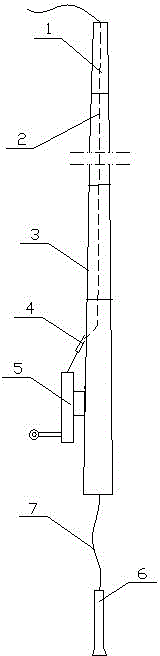

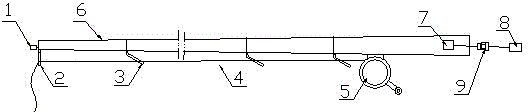

Fishing pole capable of sensing environment temperature

InactiveCN105746454AKeep track of temperature and humidityThere will be no entanglementRodsOther angling devicesEngineeringFishing line

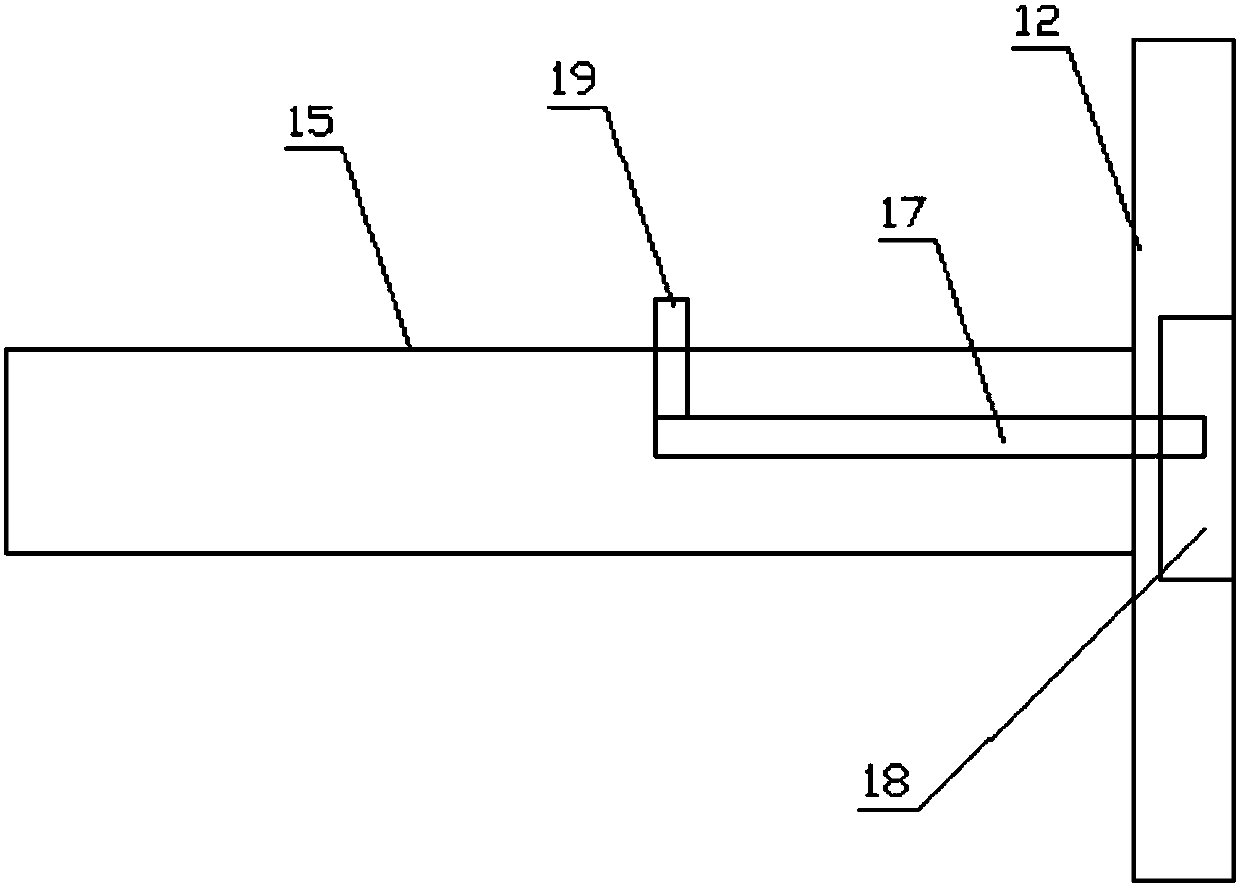

The invention relates to a fishing pole capable of sensing the environment temperature. The fishing pole comprises a telescopic rod and a fishing line, wherein the telescopic rod is composed of a plurality of short hollow rod bodies which are mutually sleeved back and forth; a shifting ring is arranged on the tip of the first short hollow rod body; a fishing line outlet is arranged in the front portion of the first short hollow rod body; a reel connected with the tail portion of the fishing line is mounted on the last short hollow rod body; a fishing line inlet is arranged in the short hollow rod body above the reel; a wire conduct is mounted in the fishing line inlet and tilts to the direction of the reel with the tilt angle ranging from 20 degrees to 60 degrees; a handle is connected to the rear end of the last short rod body; a groove is arranged in the upper portion of the handle; and a hygrothermograph is arranged in the groove. The fishing pole is simple in structure and convenient to take up and pay off, environment temperature and humidity can be mastered any time, and whether fishing is suitable or not can be judged.

Owner:宜恒琦

Fish rod

The invention relates to a fish rod comprising a telescopic rod and a fish wire. The telescopic rod is formed by a plurality of hollow short rods sleeved each other; a rod tip of the first hollow short rod is provided with a movable ring; a fish wire tap-hole is formed in the front part of the first hollow short rod; a wire winding wheel connected with the tail part of the fish wire is arranged on the last hollow short rod; the hollow short rod over the wire winding wheel is provided with a fish wire inlet hole; a lead tube is placed in the fish wire inlet; the lead tube is inclined toward the direction of the wire winding wheel and the inclination angle is 20 to 60 degrees; the back part of the last hollow short rod is provided with a supporting rack; and a micro-torch light is mounted on the supporting rack. The fish rod is simply structured; the fish wire can be conveniently collected and rolled out; and the fish rod can illuminate at night.

Owner:宜恒琦

Fishing rod suitable for nighttime use

The invention relates to a fishing pole suitable for nighttime use. The fishing pole comprises a telescopic pole body and a fishing line. The telescopic pole body is composed of a plurality of hollow short poles which are in sleeving connection orderly from front to back. A fishing line outlet hole is formed in the front part of the first hollow short pole. A line winding wheel connected to the tail of the fishing line is arranged on the last hollow short pole. A fishing pole inlet hole is formed in the hollow short pole above the line winding wheel. A line guide pipe is arranged in the fishing line inlet hole. The line guide pipe inclines towards the direction of the line winding wheel with an inclination angle of 30-65 DEG. A connection rope is arranged on the back end of the last hollow short pole. A mini flashlight is hung on the connection rope. The fishing pole has a simple structure. With the fishing pole, line reeling and casting are simple. The fishing pole also has a nighttime illumination function.

Owner:刘金红

Novel fishing pole capable of carrying fishhook

The invention relates to a novel fishing pole capable of carrying a fishhook. The fishing pole comprises a telescoping rod body, a fishing line, and a handle. The telescoping rod body is formed by a plurality of hollow short rods which are coupled with each other end to end. The rod tip of the first hollow short rod is provided with a moving ring, and the front part of the first hollow short rod is provided with a fishing line outlet hole. The last hollow short rod is provided with a reel which is connected with the tail of the fishing line. The hollow short rod above the reel is provided with a fishing line inlet hole. The fishing line inlet hole is provided with a wire conduit. The wire conduit inclines to the direction of the reel, and an inclination angle is 20-60 DEG. The front end of the handle is connected with the tail of the telescoping rod body through threads. The handle is internally provided with a fishhook placing cavity. The tail part of the handle is provided with a port communicated with the fishhook placing cavity. An end cover is arranged on the port. The fishing pole is simple in structure and convenient in take-up and pay-off, and line wrapping phenomenon would not occur. The handle on the tail is provided with the fishhook placing cavity used to hold a fishhook, so as to provide convenience for fishing.

Owner:刘金红

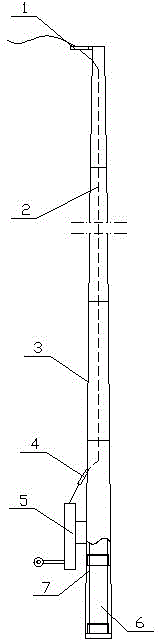

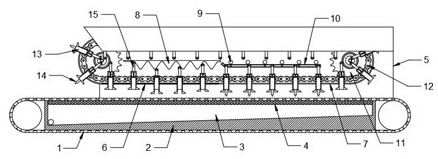

Drying, scattering and separating all-in-one machine special for household garbage treatment

ActiveCN113532039AThere will be no entanglementReduce the burden onDrying solid materials without heatDrying gas arrangementsSprocketRefuse Disposals

The invention provides a drying, scattering and separating all-in-one machine special for household garbage treatment. The drying, scattering and separating all-in-one machine comprises a belt conveyor for conveying wet garbage, water permeable holes are uniformly distributed on a belt of the belt conveyor, a support plate capable of supporting the upper belt is installed in the belt conveyor, fixing plates are fixed on racks on two sides of the belt conveyor, two pairs of chain wheels are installed between the fixing plates on the two sides, chains are correspondingly arranged between the two pairs of chain wheels in a sleeve mode, a plurality of installation blocks are installed between chain plates of the chains on the front side and the rear side in a one-to-one correspondence mode, and sliding grooves are formed in the bottoms of the installation blocks. According to the device, the wet garbage can be continuously conveyed through the belt conveyor, the blocky wet garbage can be scattered through the arranged scattering area, then excessive water is extruded out through the extrusion area, finally, the garbage is evenly turned through the turning area, the garbage is rapidly dried through hot air, the drying efficiency is high, and feeding and discharging are convenient and fast.

Owner:江苏思源环境修复有限公司

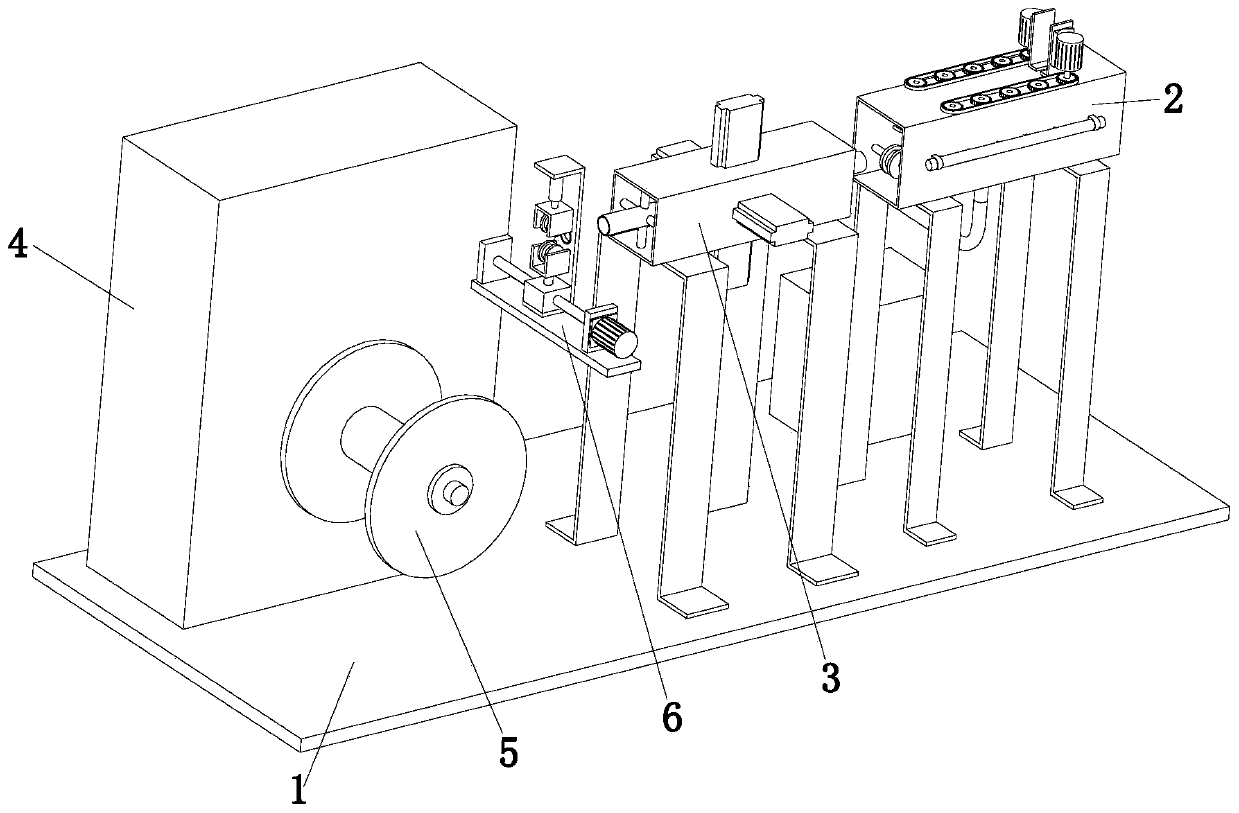

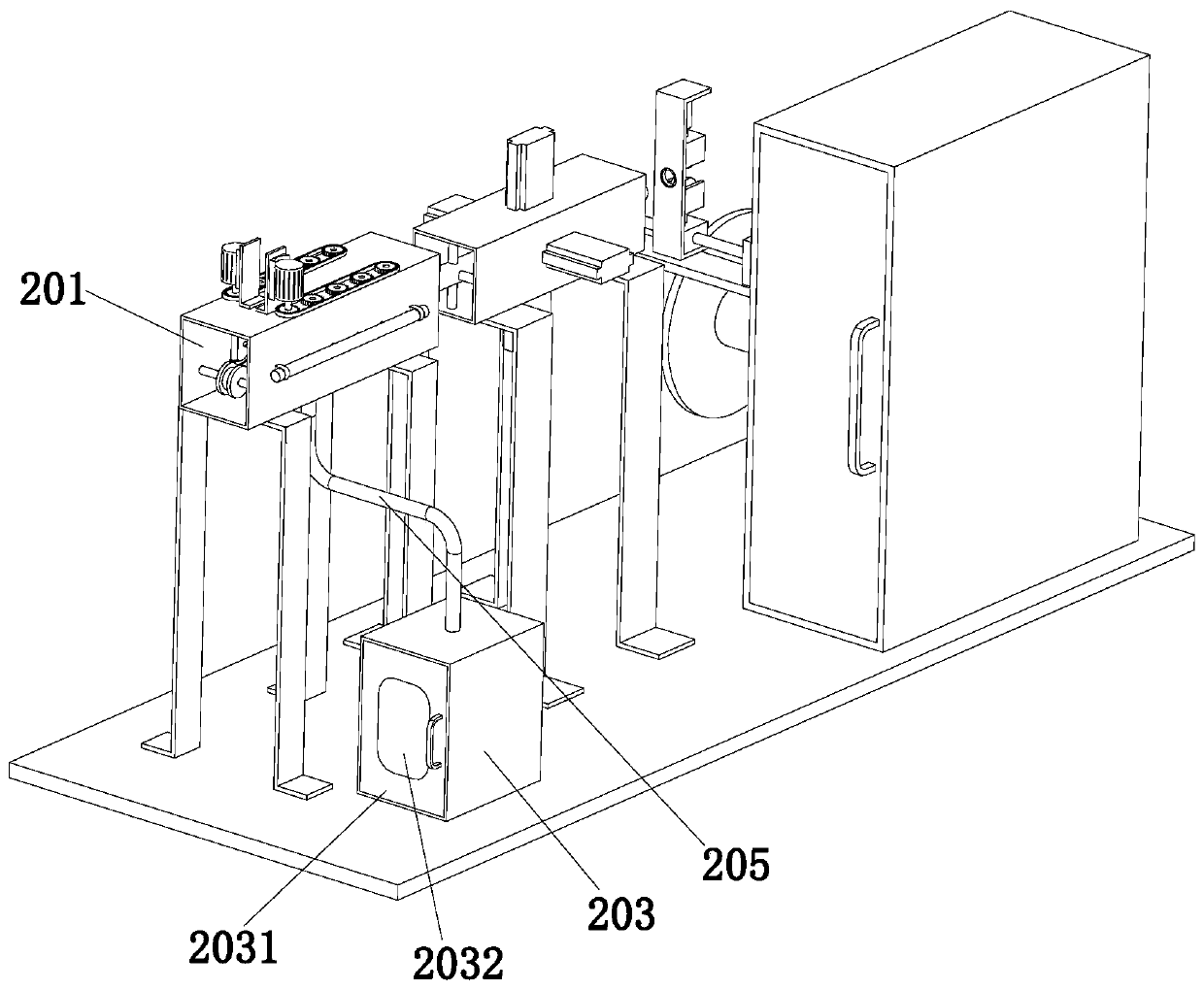

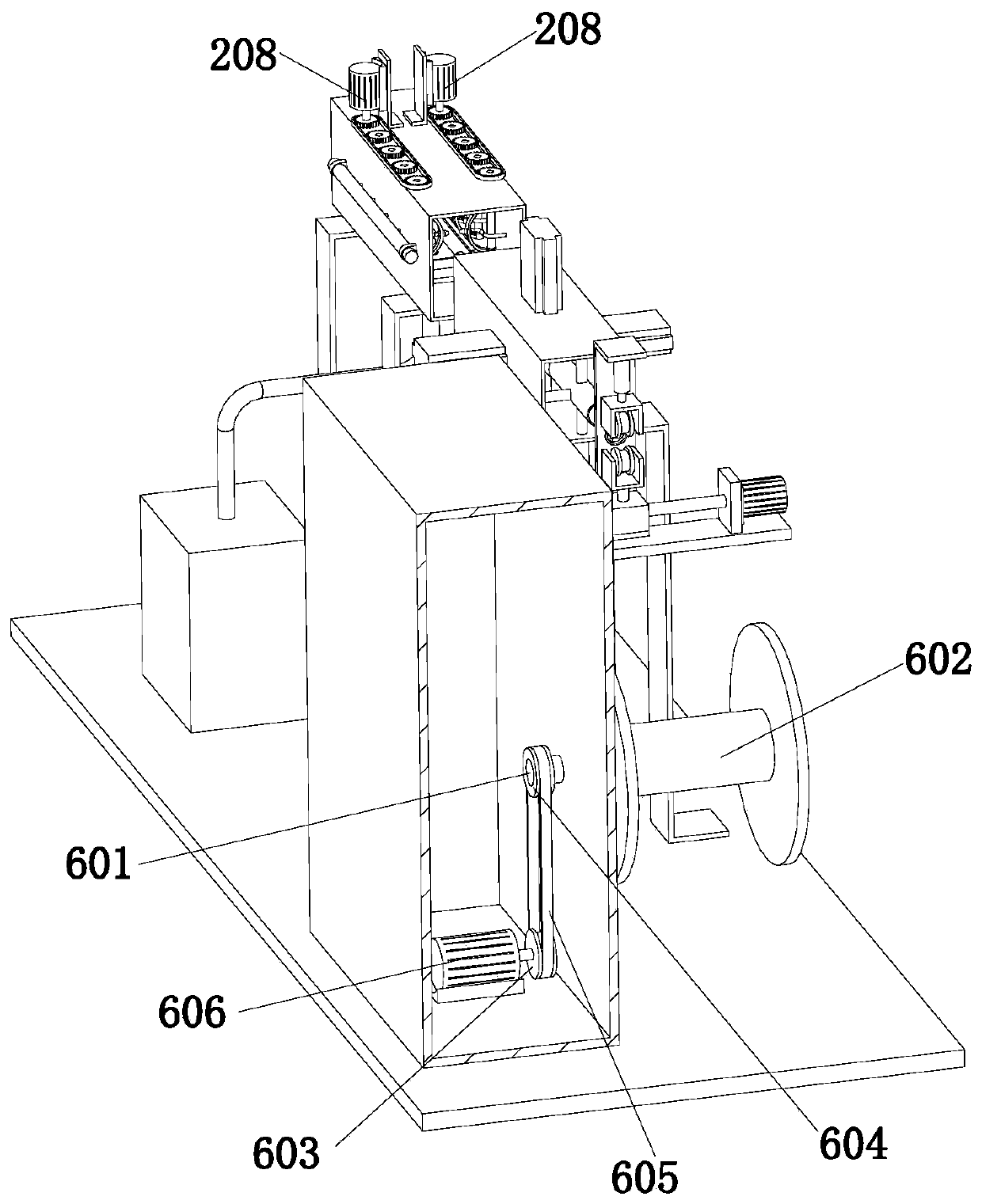

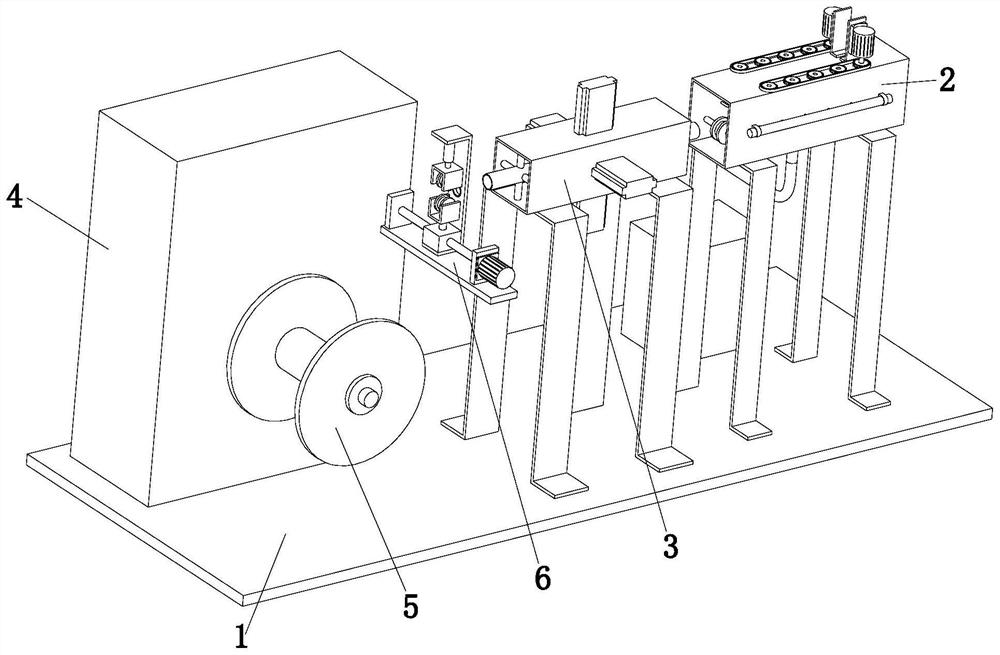

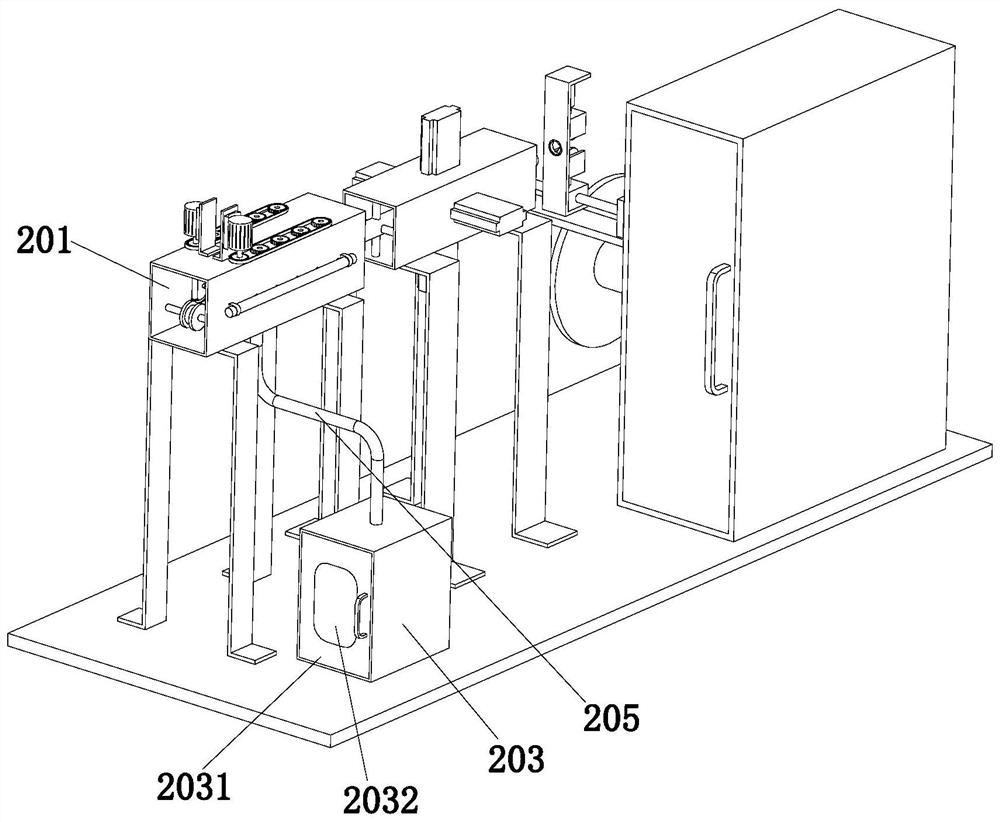

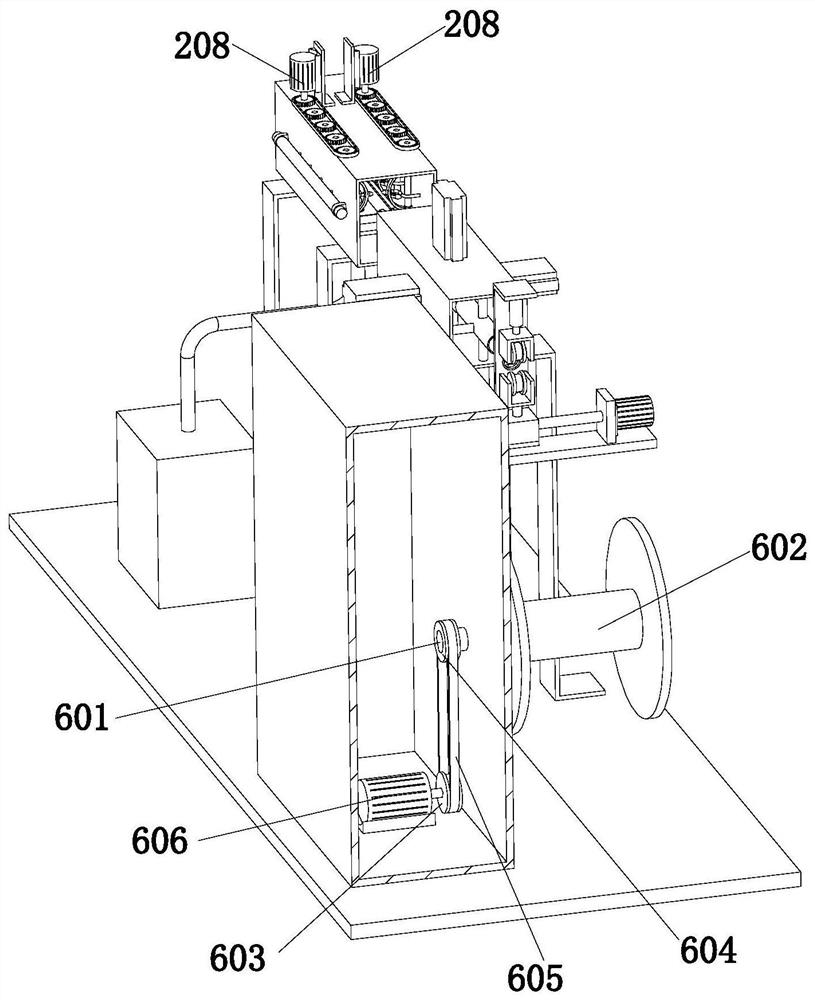

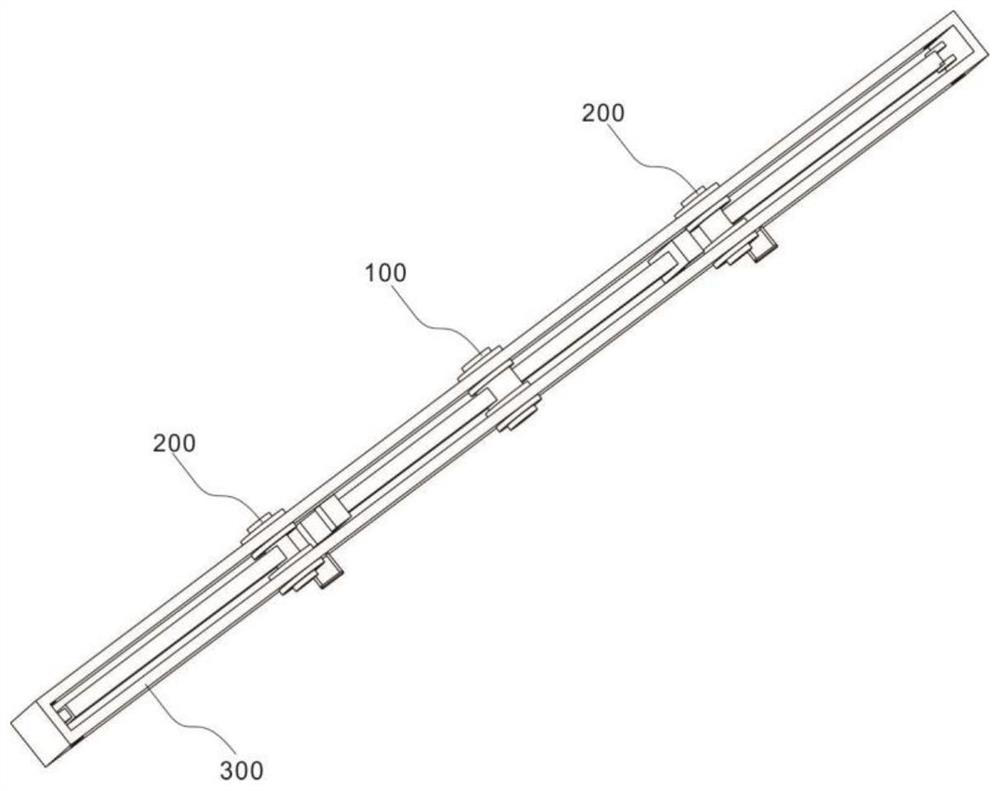

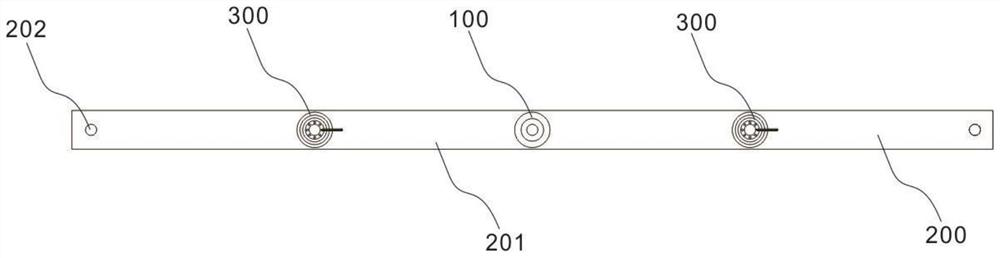

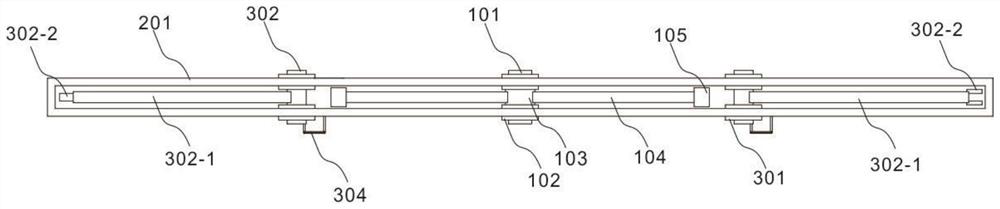

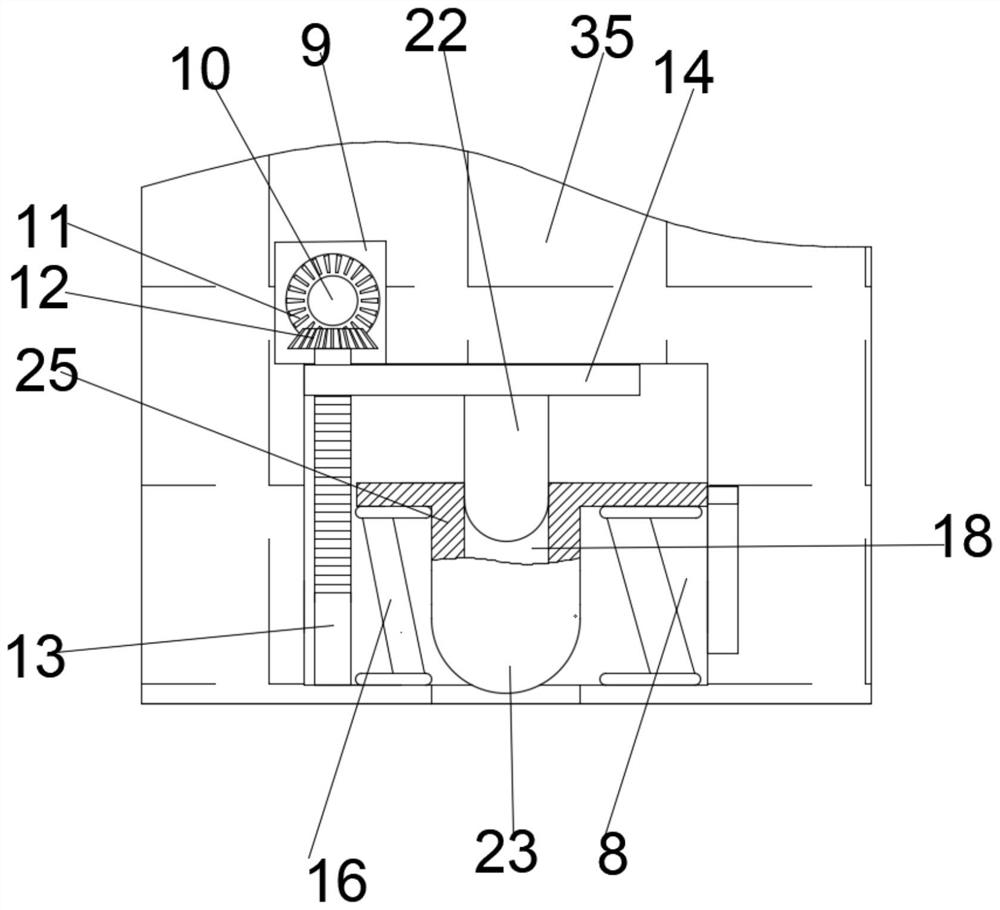

A cable rotary winding device

ActiveCN110615319BEasy to cleanAvoid gatheringFilament handlingCleaning using toolsEngineeringStructural engineering

The invention discloses a cable rotary rewinding device, which belongs to the technical field of cable rewinding and includes a bottom plate, a first cleaning component, a second cleaning component, a rewinding box, a pressing moving component and a rewinding component. The bottom plate is provided with On the ground, the first cleaning component and the second cleaning component are arranged on the bottom plate in sequence, the rewinding box is arranged vertically on the bottom plate, and the rewinding box is located on the third Next to the two cleaning components, the rewinding component is installed on the rewinding box, the pressing and moving component is arranged on the outer wall of the rewinding box, and the pressing and moving component is located on the rewinding box. between the volume assembly and the second cleaning assembly. The invention solves the problem that dust on the surface of the cable can only be cleaned by using an arc-shaped wiping block alone, and the cleaning effect is poor.

Owner:永新县宏展电线电缆有限公司

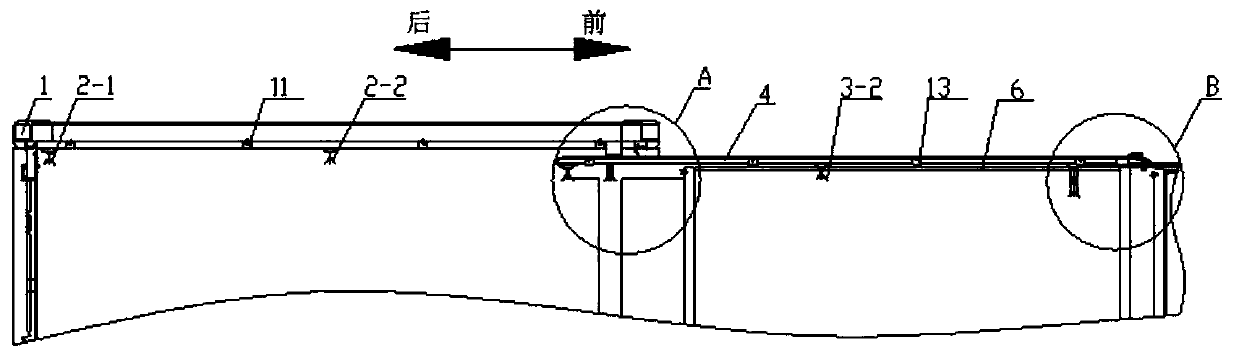

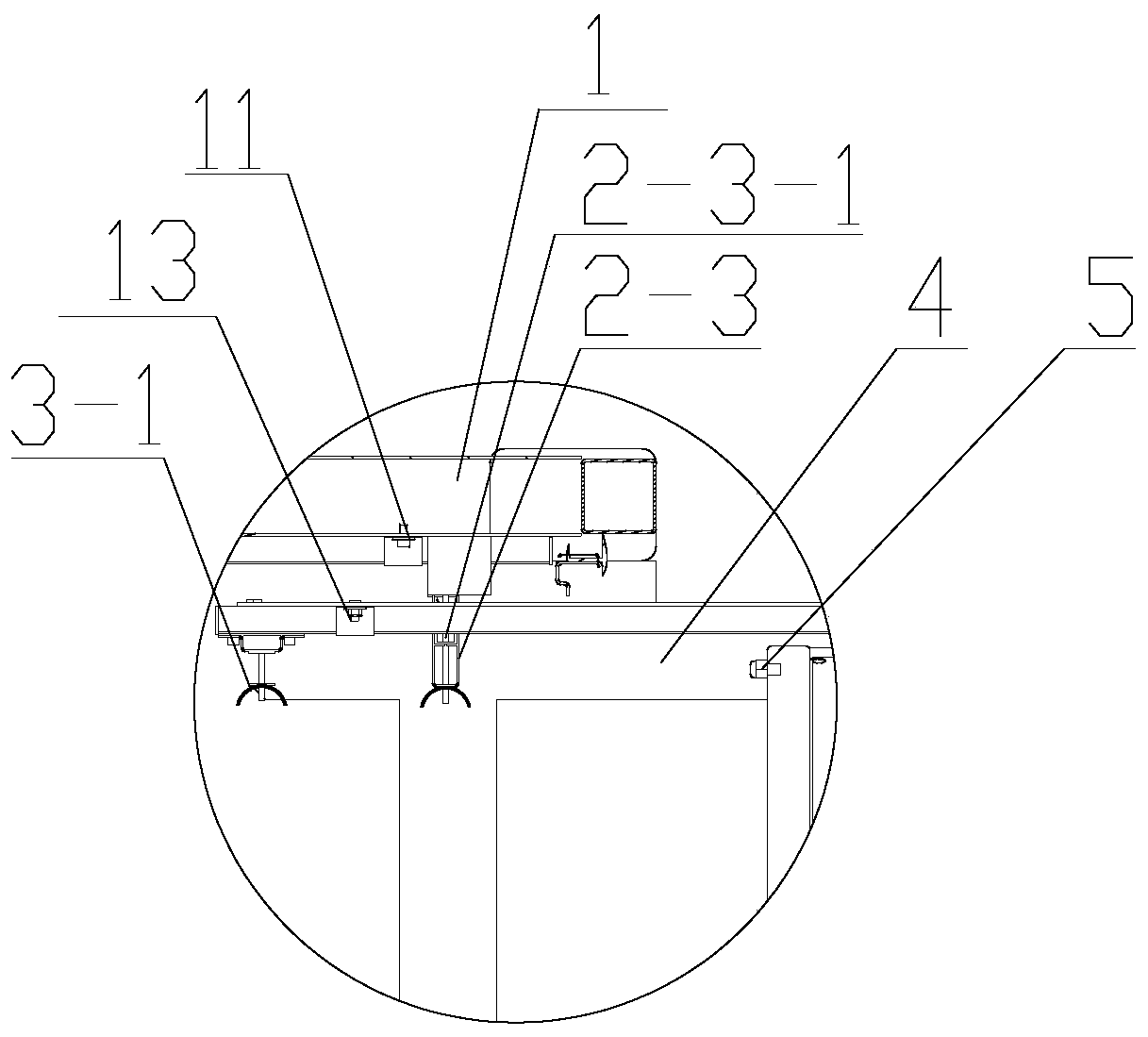

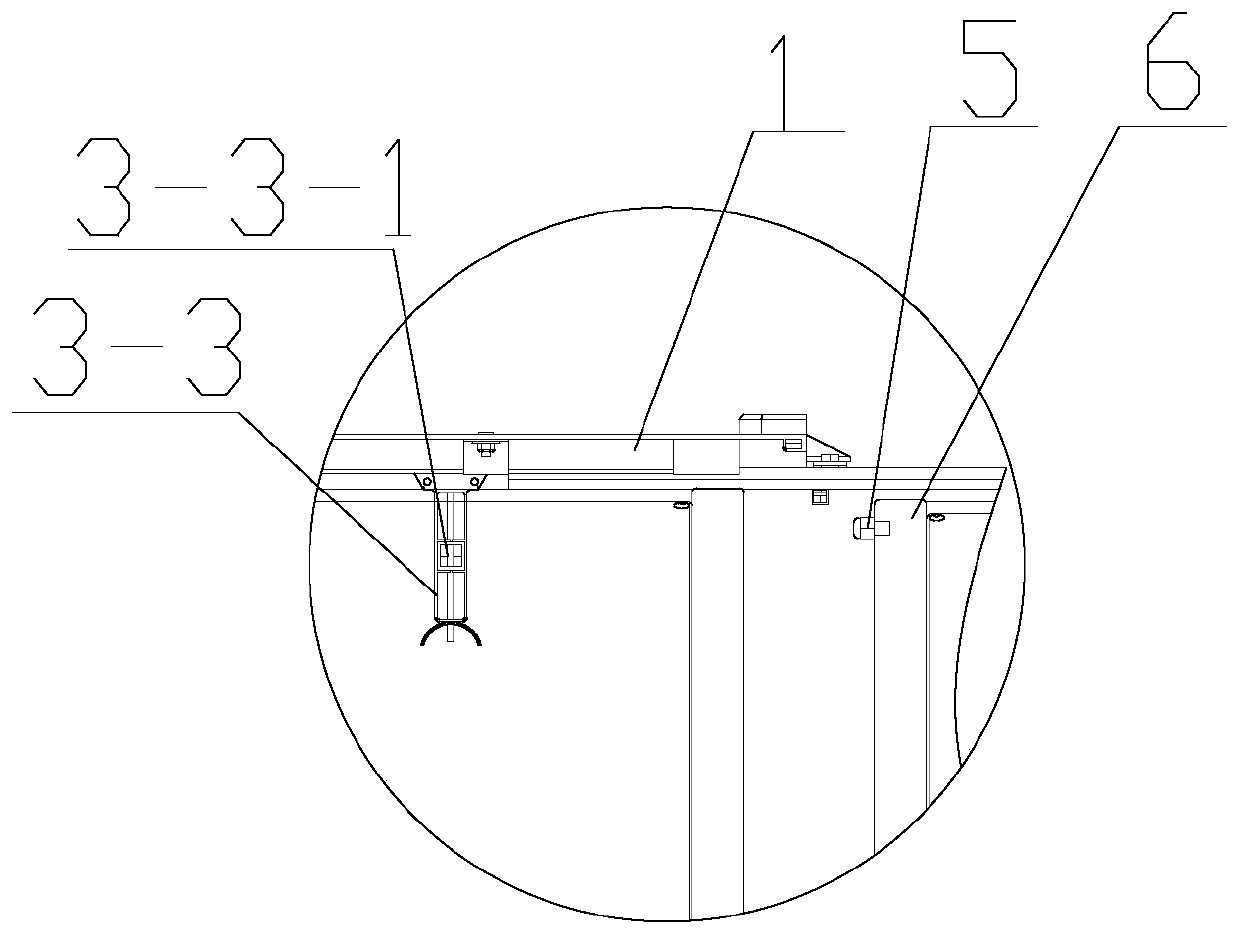

Multistage drawing type photovoltaic panel wiring structure

PendingCN110113001AImplement automatic expansionAchieve collapsePhotovoltaicsPhotovoltaic energy generationElectric shockPulley

The invention discloses a multistage drawing type photovoltaic panel wiring structure. The structure comprises a container, at least two-level frames, a pulley assembly and a photovoltaic cable, the rear side of the upper portion of each-level frame is provided with a photovoltaic panel plug-in, and the photovoltaic cable led out from the photovoltaic panel mounting frame of each-level frame passes through the photovoltaic panel plug-in on the corresponding frame, then passes out from a first-stage sliding wire tail trolley after passing through each sliding wire assembly backwards in order, and access a combiner box. The multistage drawing type photovoltaic panel wiring structure is applied to vehicle-mounted mobile photovoltaic, when a mechanism is pulled out and a photovoltaic panel isunfolded, power can be directly generated without rear wiring; when the mechanism is retracted, the photovoltaic panel does not need to be taken out of wires before being folded. Time is saved, efficiency is high, the hidden trouble is avoided that the positive and negative poles of each path are easily matched by mistake during on-site post-wiring, the hidden trouble of electric shock caused by hot-line plugging and unplugging of the photovoltaic air plug is avoided, and therefore, the multistage drawing type photovoltaic panel wiring structure is convenient and efficient, and safe to operate.

Owner:中国人民解放军32181部队

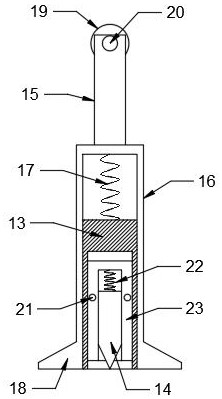

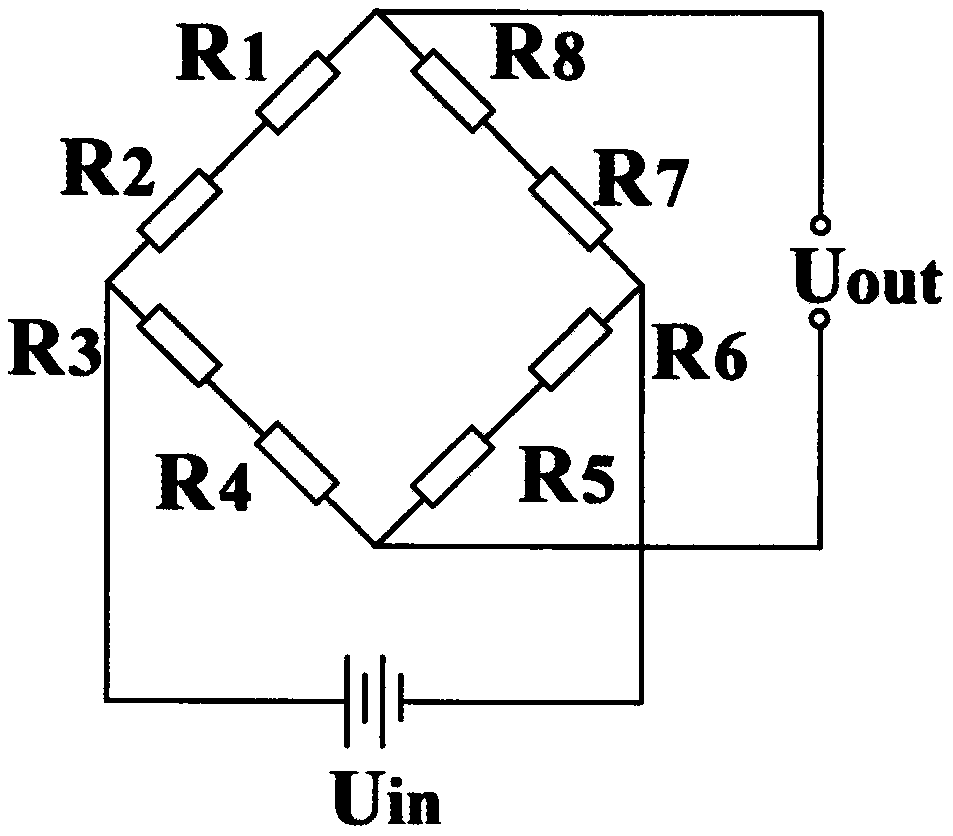

Gate lifting weight detection sensor

The invention discloses a gate lifting weight detection sensor, and belongs to the field of weight sensors. The gate lifting weight detection sensor comprises a supporting base, an elastomer and a resistance type strainometer. The resistance type strainometer is pasted on the elastomer to form an equal arm bridge structure, the elastomer is subjected to the pressure of a winch, a wire rope and a gate to cause the resistance type strainometer to generate micro deformation, such that a bridge output voltage changes, and then weight data are obtained according to the voltage change. The sensor has a large measuring range, a small installation space, a simple structure and convenient installation. Since the gate lifting weight detection sensor does not need to be installed on the wire rope, the phenomenon of cable entanglement that follows the movement of the wire rope does not occur. When the gate encounters jamming, wire rope breakage, slipping and other faults, the load on the sensor changes significantly, and operators can immediately determine that the gate is in an abnormal operating state based on this change and take measures to avoid dangerous accidents.

Owner:BENGBU COLLEGE

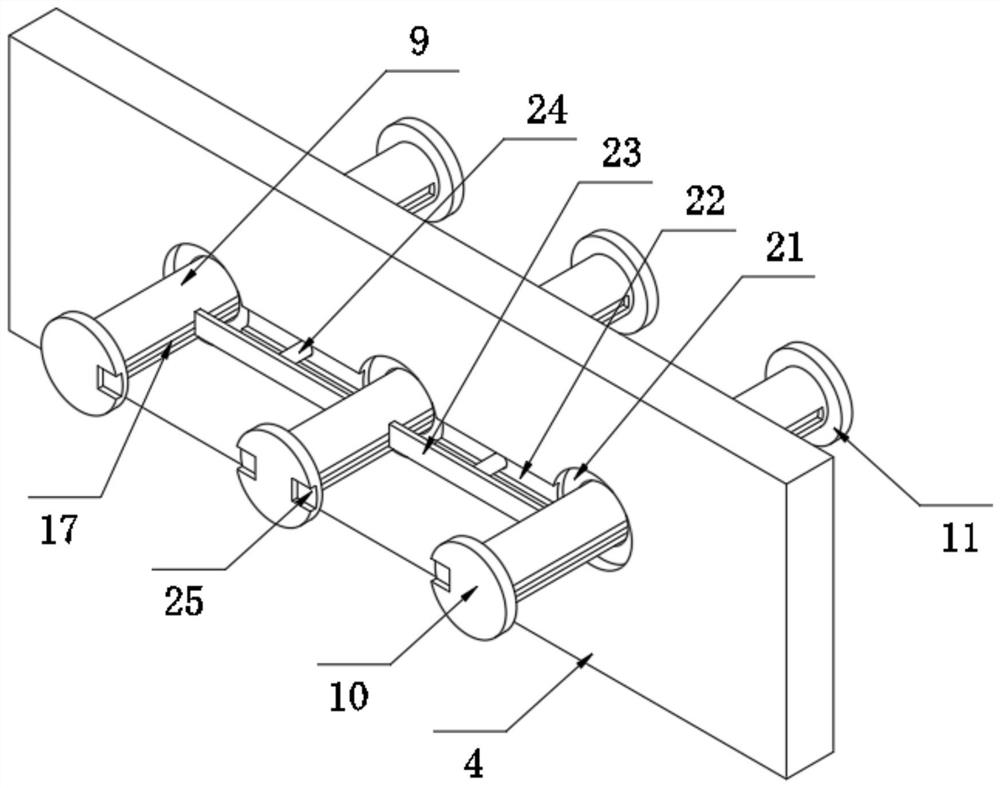

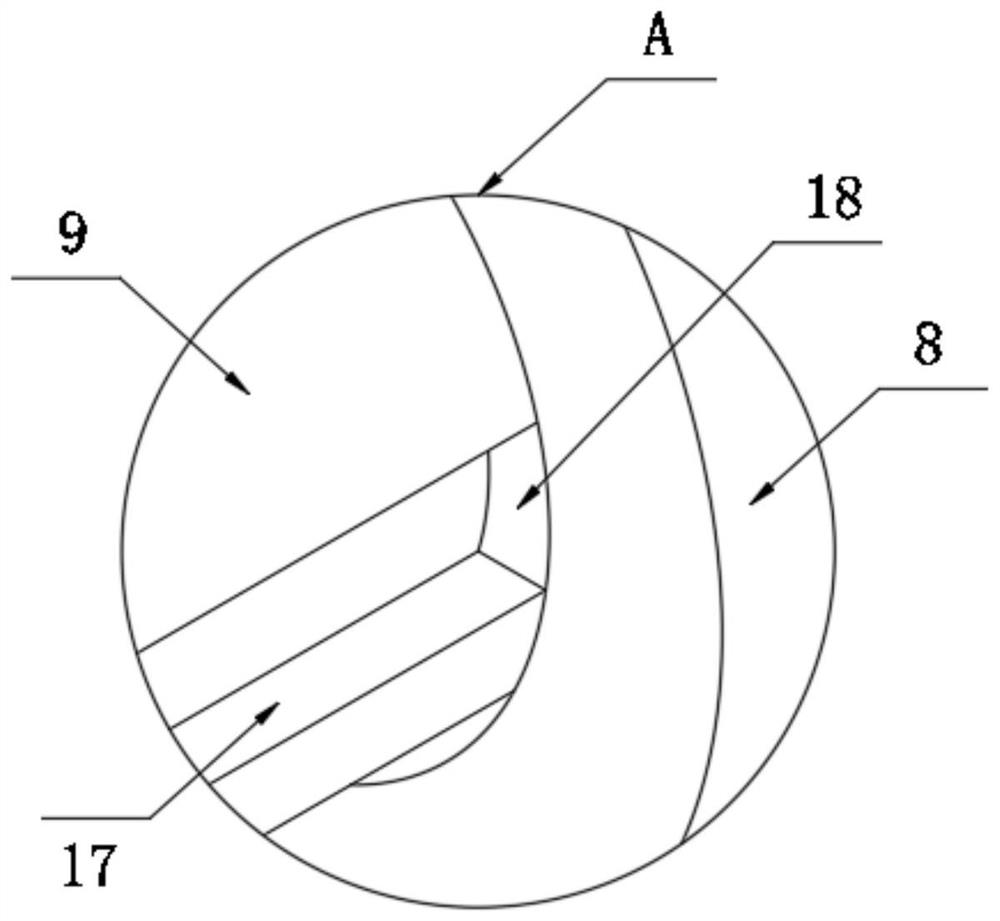

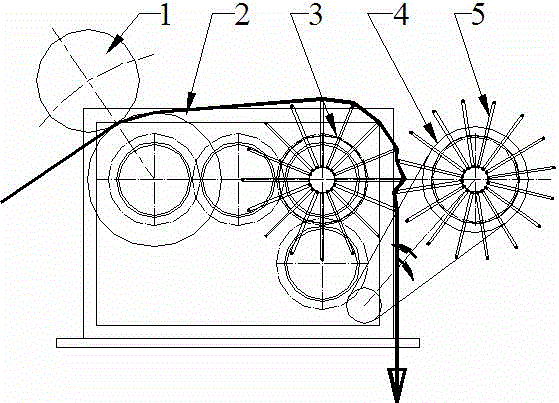

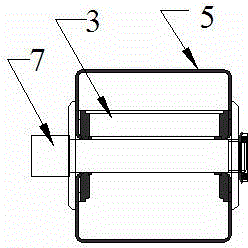

Filament bundle conveying paired wheel device

The invention discloses a filament bundle conveying paired wheel device. The filament bundle conveying paired wheel device comprises an adhesive pressing wheel. The back of the adhesive pressing wheel is connected with a filament bundle conveying paired wheel device body. The filament bundle conveying paired wheel device body comprises a first paired wheel and a second paired wheel matched with the first paired wheel. The first paired wheel is fixedly arranged behind the adhesive pressing wheel. The second paired wheel is arranged behind the first paired wheel and connected with an air cylinder. An air cylinder push rod on the air cylinder makes the second paired wheel get close to or away from the first paired wheel. The first paired wheel and the second paired wheel both comprise a rotating shaft and steel wire wheel teeth outside the rotating shaft. The steel wire wheel teeth of the first paired wheel and the second paired wheel are semi-open rectangular frame-shaped steel wire wheel bands parallel with the axes of the rotating shafts. According to the technical scheme, the filament bundle conveying paired wheel device is suitable for 0.1 K-200 K filament bundles and capable of meeting the requirement for freely adjusting the filament bundle moving speed from 0 m / min to 1000 m / min; neither high-speed moving conveying nor low-speed moving conveying will cause air-pressure disturbance to the filament bundles, and therefore it is guaranteed that the filament bundles move stably.

Owner:安徽安强机电工程有限公司

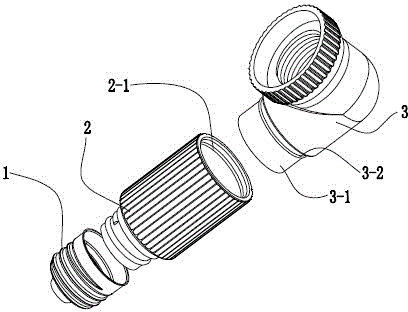

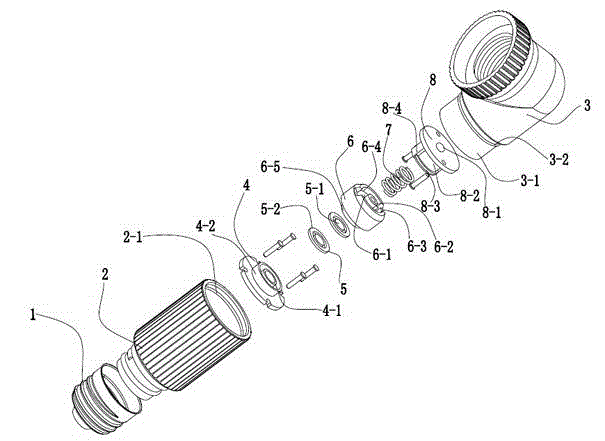

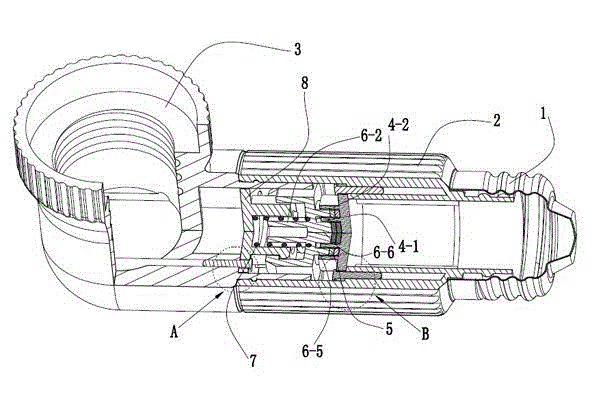

Lamp holder assembly with rotatable direction adapter

ActiveCN102997195BImprove stabilityThere will be no entanglementLighting support devicesEngineeringLight head

The invention discloses a lamp holder, in particular to a lamp holder assembly with a rotatable direction adapter. The lamp holder assembly with the rotatable direction adapter comprises a lamp holder and a plastic base, wherein the lamp holder is connected with one end of the plastic base. The lamp holder also comprises a tubular adapter, a rotating shaft extends on one end surface of the adapter, a bulge loop is arranged on the surface of the adapter, a ring groove is arranged on the inner wall of the plastic base, the rotating shaft is inserted in the plastic base, and the rotating shaft and the plastic base are bucked and fastened through the bulge loop and the ring groove. The lamp holder assembly with the rotatable direction adapter solves the technical disadvantage that the illumination angle cannot be adjusted after a lamp source is arranged on the traditional lamp holder; and the lamp holder assembly with the rotatable direction adapter is mainly used in a situation needing illumination from a specific angle, and has the advantages that the illumination angle of the lamp can be adjusted and the illumination from a specific angle is realized.

Owner:NINGBO FUTAI ELECTRIC CO LTD

Novel high-performance fishing pole

The invention relates to a novel high-performance fishing pole comprising a telescopic pole body and a fishing line. The telescopic pole body is composed of a plurality of short poles sleeved orderly one-after-another. A moving ring is arranged on the tip of the first short pole. A line threading ring for threading the fishing line is arranged on the front part of each of the rest short poles. Each line threading ring has an inclination angle of 30 DEG relative to the entire telescopic pole body, and is inclined towards the back end of the short pole. A line reel is arranged on the last short pole. The tail of the fishing line is connected with the line reel. A weight sensor is arranged on the front end of the first short pole. A vibration device is arranged on the last short pole behind the line reel. The weight sensor communicates with the vibration device through a signal line. The vibration device is connected to a power source device through a conductor wire. A set of quick connectors are arranged on the conductor wire. The fishing pole has a simple structure. With the fishing pole, line casting and reeling are convenient, and whether a fish is hooked can be accurately sensed.

Owner:刘金红

A kind of integrated medicine crushing and brewing device for medical use and its application method

ActiveCN112246355BGuaranteed grinding effectImprove reliabilityRotary stirring mixersTransportation and packagingPharmacy medicineMechanical engineering

The invention discloses a medical integrated device for crushing medicine and brewing medicine and its use method, and relates to the technical field of medicine crushing and brewing device; in order to improve the effect of crushing medicine; the device includes a main body, the outer wall of the main body is integrally provided with a water box, The inner wall of one side of the box is threadedly connected with a regulating valve to control the conduction and closure of the water box and the inside of the main body. The threaded connection has a sealing cover; the use method of the device includes the following steps: the user prepares the brewing tablet and needs to cut it and turn it into step S2, otherwise turn it into step S3; unscrew the top cover and use the drug cutting protrusion and The medicine cutting ribs cut the medicine tablets. In the present invention, through the arrangement of sliding balls, linkage grooves and other structures, the grinding head can realize the grinding of medicines by pressing the pressing rod in the form of pressure and rotating torque; the grinding effect is guaranteed and the reliability is improved.

Owner:陈林

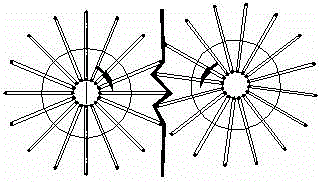

A 0.4kv line interphase anti-collision device

ActiveCN111564805BThere will be no entanglementAvoid short circuitMaintaining distance between parallel conductorsRotational axisCustomer delight

The invention discloses a 0.4kV line phase-to-phase anti-collision device. The anti-collision device includes a rotating unit, a bearing unit, an adjusting unit and a limit unit. The rotating unit includes a first rotating shaft and two The first limit block at the end, the bearing unit, is fixedly connected with the rotation unit through the first limit block, and the adjustment unit is connected with the load unit through a bearing shaft; and the limit unit is fixed with the inner wall of the first limit block through the first The block is fixedly connected; the present invention separates the lines through the mutual cooperation among the rotating unit, the carrying unit, the adjusting unit and the limit unit, so as to ensure that the lines will not appear due to the excessive sag of the lines, under the influence of wind and external forces. Under the action, the wires with lower sag will be entangled together, thereby further avoiding the short circuit of the low-voltage line, the voltage rise, and the burning of user equipment, ensuring the reliability of power supply and improving customer satisfaction.

Owner:GUIZHOU POWER GRID CO LTD

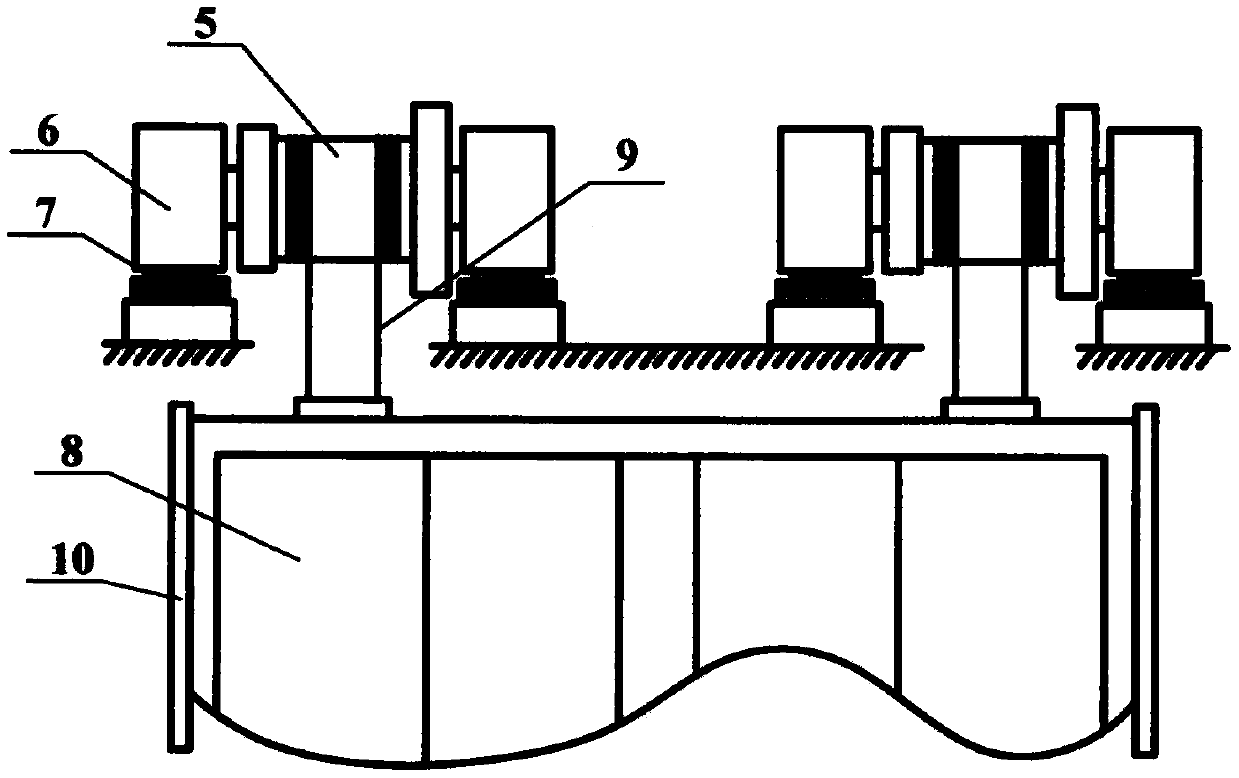

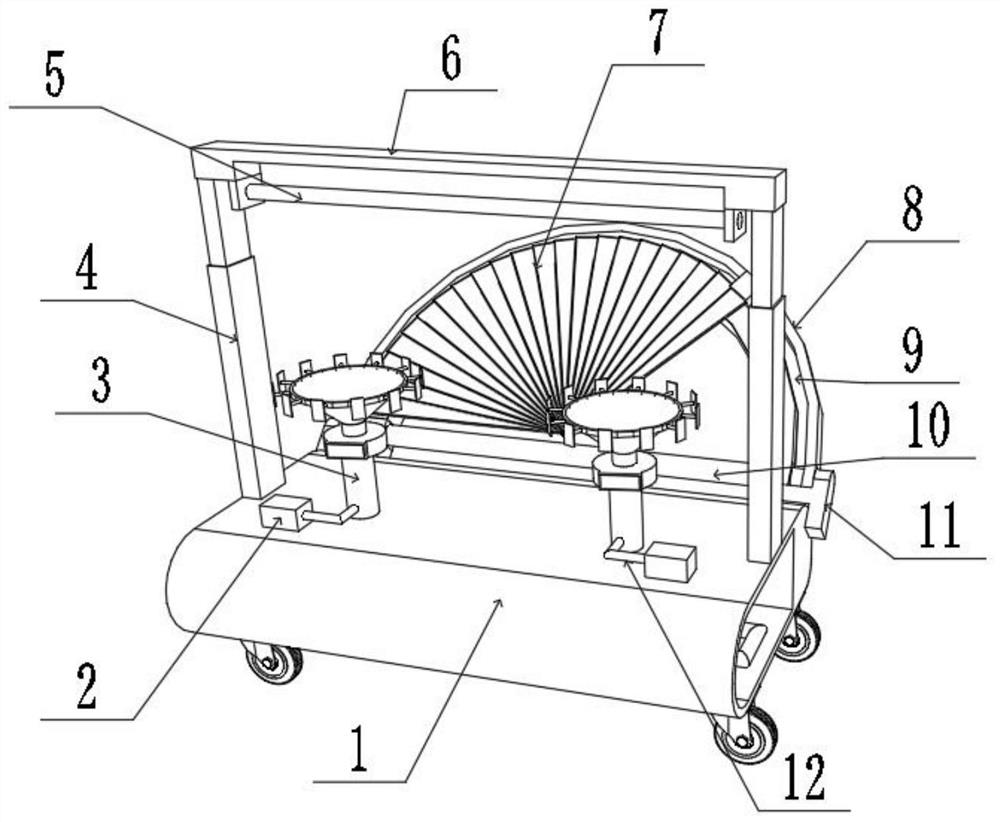

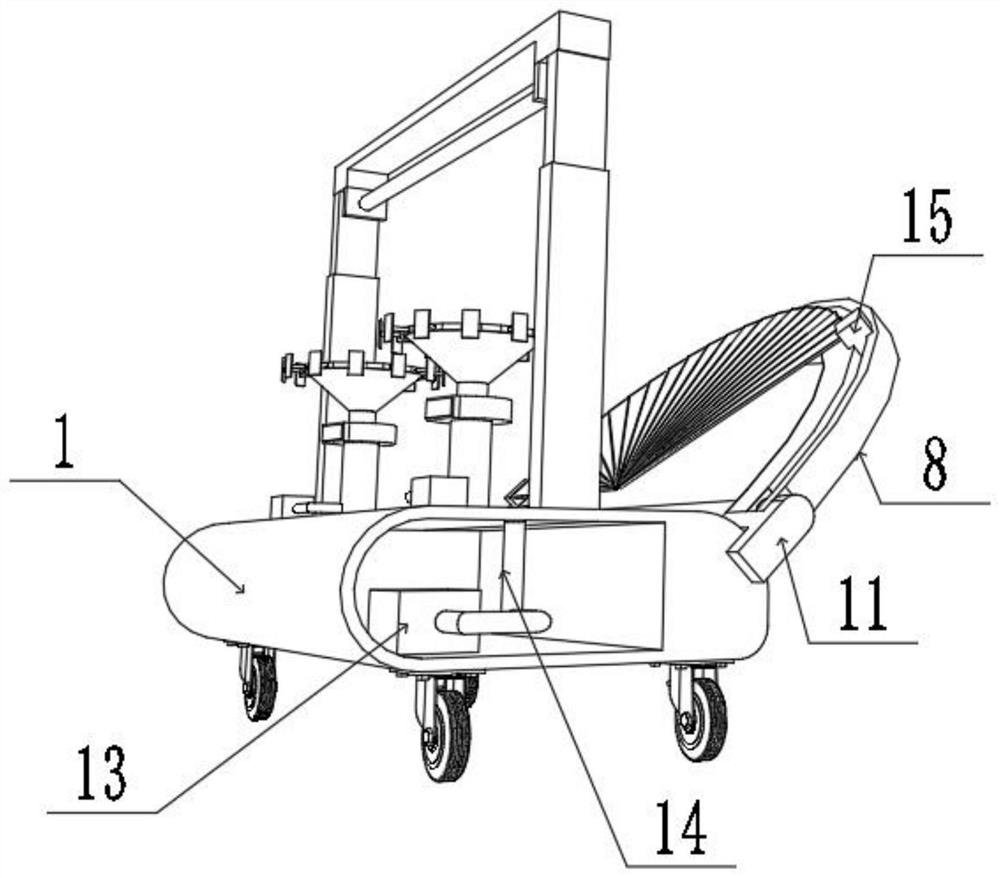

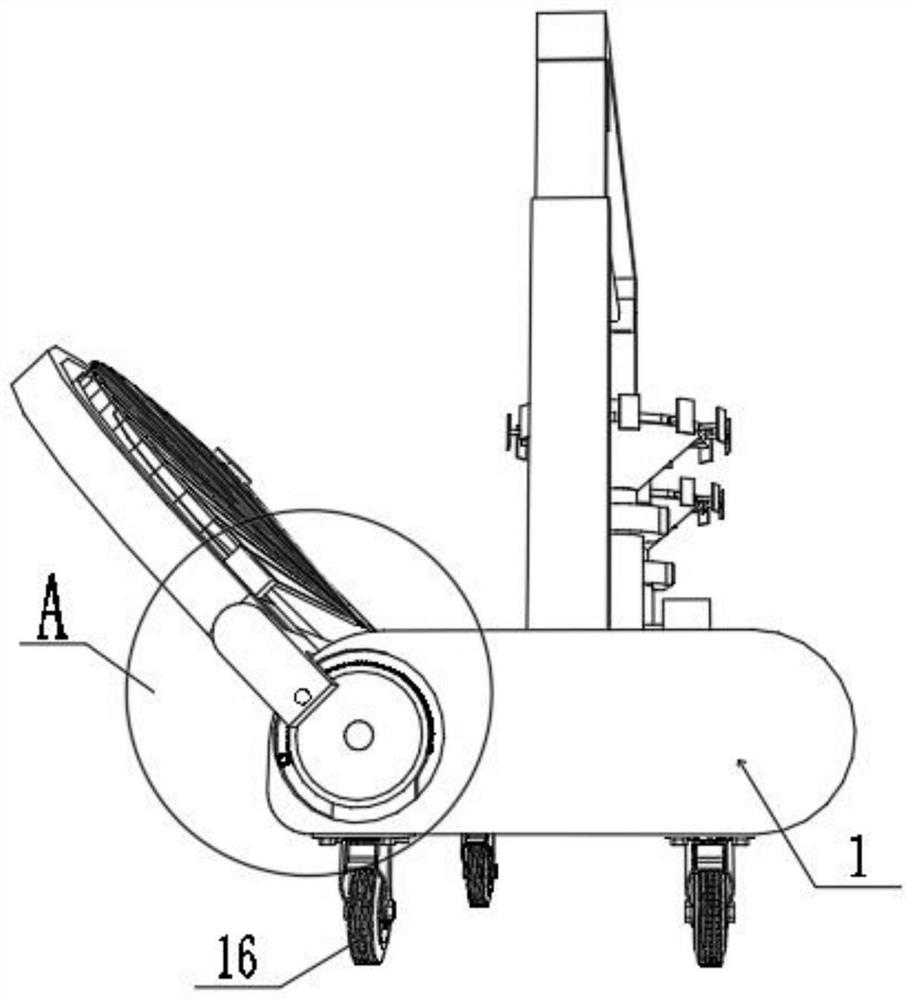

A semi-submersible sewage treatment aeration equipment

ActiveCN107265680BThere will be no entanglementSave the process of repair and maintenanceWater aerationSustainable biological treatmentInertial effectSewage treatment

Owner:中际通达水处理装备研究院(江苏)有限公司

Wire coiling and winding take-up machine

The invention relates to the technical field of electric power, and discloses a wire coiling and winding take-up machine which comprises a base, an inner cavity column, a winding drum, a supporting column, a take-up assembly, a centrifugal assembly and a tensioning assembly, wherein the top end of the base is fixedly connected with the inner cavity column, the left side of the inner wall of the inner cavity column is movably connected with the take-up assembly, the outer wall of the take-up assembly is movably connected with the winding drum, the top end of the base is located on the left side of the take-up assembly and fixedly connected with the supporting column, the bottom end of the take-up assembly is movably connected with the centrifugal assembly, and the top end of the inner wall of the base is located above the centrifugal assembly and movably connected with the tensioning assembly. According to the wire coiling and winding take-up machine, a crank is rotated to drive a transmission shaft to move, the transmission shaft drives the inner column to rotate, the inner column drives a winding drum to move left and right on the transmission shaft in a reciprocating mode through a snakelike groove and a rolling ball, so that an electric wire winds on the winding drum neatly and evenly, and the electric wire needed to be used can be rapidly unfolded, and a situation that the electric wires are wound together is avoided.

Owner:王文

A clothes drying device

ActiveCN110791932BThere will be no entanglementNo uneven dryingTextiles and paperLaundry driersElectric machineryStructural engineering

The invention discloses a clothes drying device, which relates to the technical field of clothes drying; in order to solve the problem that the drying of thin clothes and skirts is inconvenient and easily leads to damage to the clothes and skirts; it specifically includes a base, and both sides of the top of the base are connected by bolts. The push rod motor is fixed, and the top of the two push rod motors is fixed with the same connecting frame by bolts, and the bottom end of the connecting frame is welded with a hanging rod; the inner wall of the top of the base is fixed with several bottom support mechanisms by screws and a negative pressure pump, the suction end of the negative pressure pump communicates with the bottom support mechanism through an air guide tube. In the present invention, by setting the bottom support mechanism, the negative pressure pump works, and the suction piece can be drawn through the connection of the connecting pipe to form a negative pressure. Fitting results in uneven drying; with this device, the clothes do not interfere with each other, and there is no phenomenon of entanglement.

Owner:湖南浚林服饰有限公司

Foldable fire hose

PendingCN114321549ANeatly foldedEasy to foldFire rescuePipe elementsSuction forceStructural engineering

The invention discloses a foldable fire hose, and relates to the technical field of fire fighting, the foldable fire hose comprises a fire hose body, the outer side of the fire hose body is sleeved with a plurality of limiting rings, one end of each limiting ring is provided with a mounting ring, and creases are arranged on the outer side of the fire hose body and located between the mounting rings. The foldable fire hose comprises a fire hose body, a limiting ring is arranged in the fire hose body, a storage groove is formed in the limiting ring, one end of an inner cavity of the storage groove is rotationally connected with a lead screw, and the outer side of the lead screw is in threaded connection with a push plate. And limiting rings on the outer side of the fire-fighting belt body make up-and-down contact, at the moment, due to attraction force between a magnet and a magnetic block, a jacking column moves downwards into a supporting spring, the folded fire-fighting belt body is limited through the magnetic attraction force, the fire-fighting belt body is folded more orderly, and therefore the fire-fighting belt body is folded conveniently.

Owner:江苏泰华消防电气设备有限公司

Novel fish rod

The invention relates to a novel fish rod comprising a telescopic rod body and a fish wire. The telescopic rod is formed by a plurality of short rods sleeving each other back and forth; a movable ring is mounted on a rod tip of the first short rod; the front parts of the rest short rods are respectively provided with a wire loop, through which the fish wire can pass; an included angle between each wire loop and the whole telescopic rod is 30 degrees; the back end of each short rod is inclined; a wire winding wheel is mounted on the last short rod; the tail part of the fish wire is connected with the wire winding wheel; the back part of the last hollow short rod is provided with a supporting rack; and a micro-torch light is assembled on the supporting rack. The novel fish rod is simply structured, the fish wire can be conveniently collected and rolled out; and the novel fish rod can illuminate at night.

Owner:宜恒琦

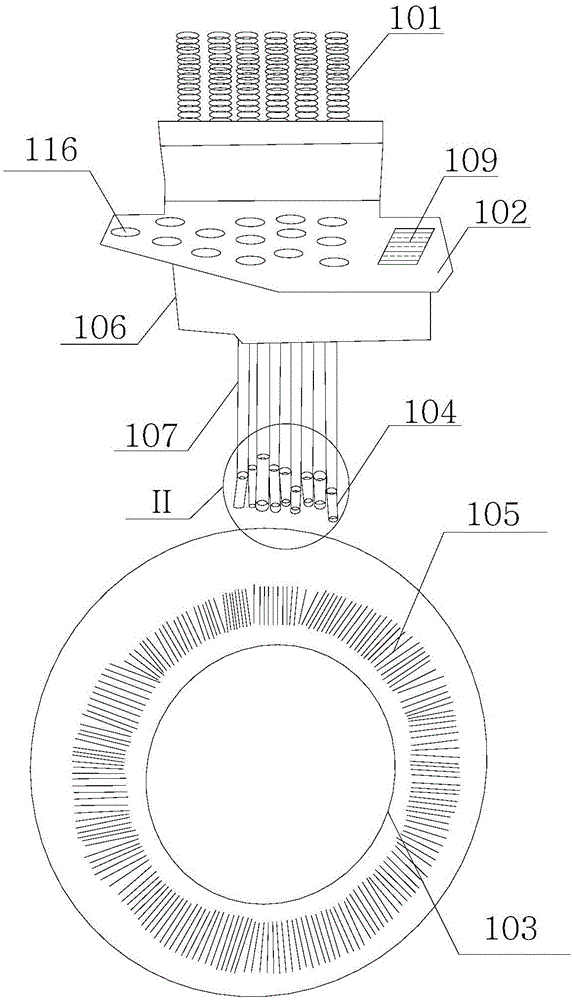

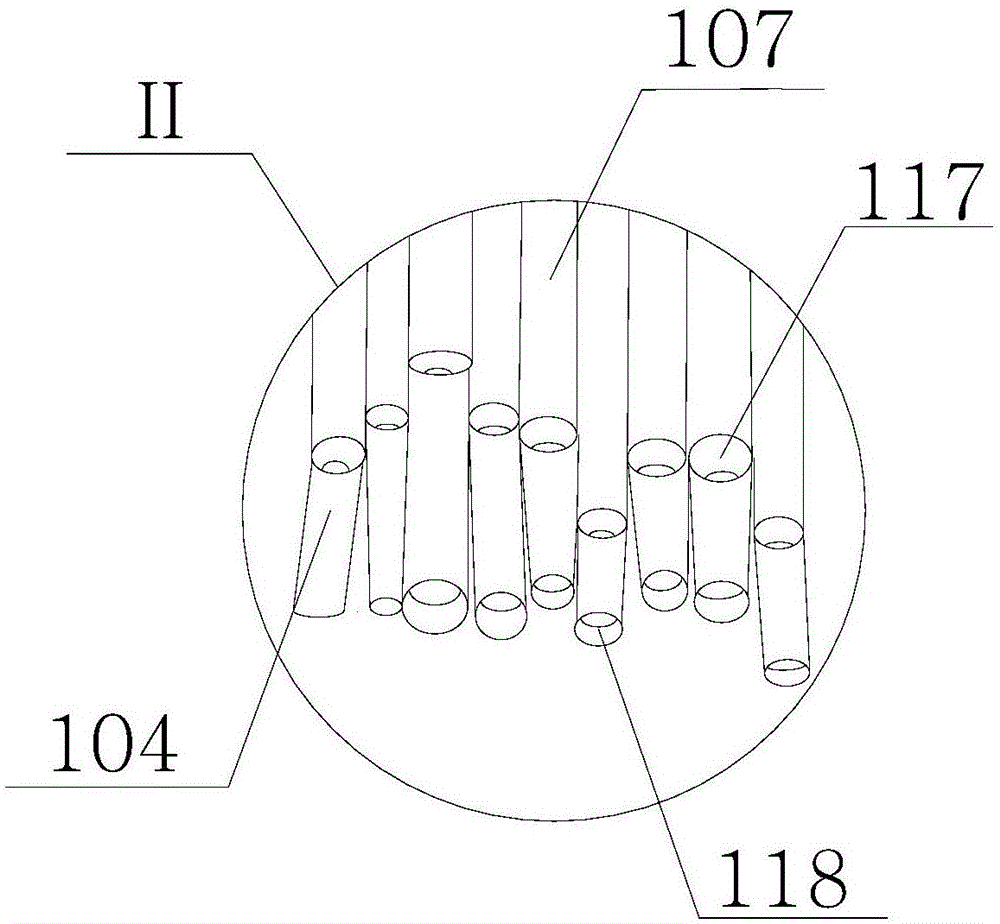

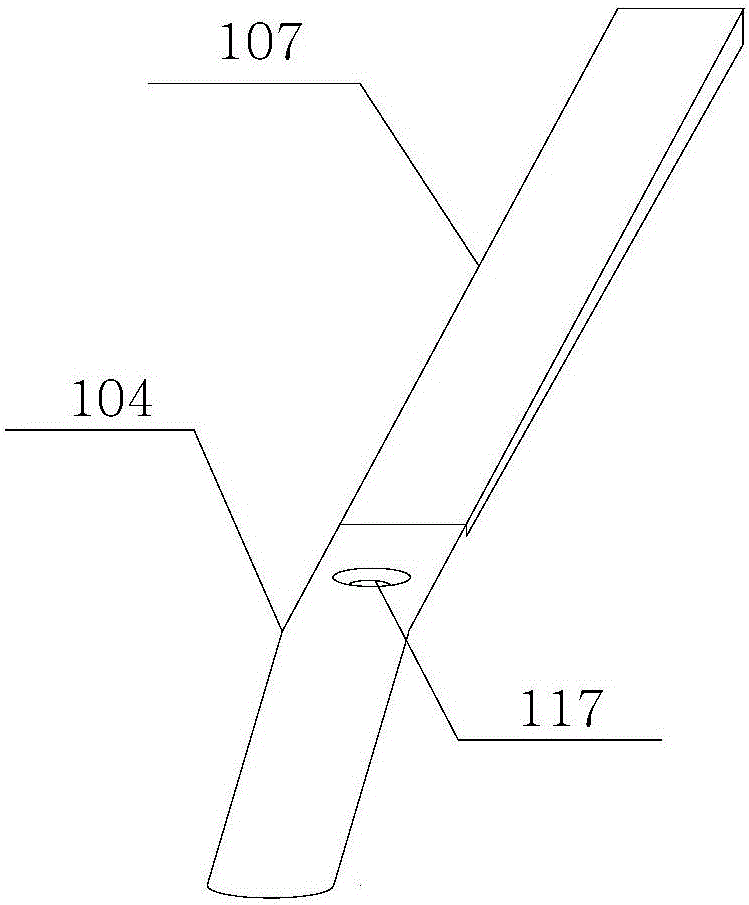

Thread guide mechanism of hosiery knitter

The invention provides a thread guide mechanism of a hosiery knitter and relates to the field of hosiery knitters. The thread guide mechanism comprises a spring, a thread guide plate, a hosiery knitting cylinder and a plurality of thread guide tubes. Due to the fact that one end of one thread guide tube located on one side of the thread guide tubes is inclined towards the ground, breaking and intertwining during the operation of the hosiery knitter can be avoided, and the production efficiency of the hosiery knitter is increased.

Owner:江苏舒跑科技有限公司

An all-in-one drying, dispersing and separating machine dedicated to domestic waste treatment

ActiveCN113532039BThere will be no entanglementReduce the burden onDrying solid materials without heatDrying gas arrangementsProcess engineeringRefuse Disposals

Owner:江苏思源环境修复有限公司

An anti-blocking drum screen

The invention provides an anti-blocking rotary screen, and relates to the technical field of screening equipment, so as to solve the problem that the comb-type cleaning device of the existing anti-blocking rotary screen is bad in cleaning effect and easy to be damaged. The anti-blocking rotary screen comprises a rotationally installed cylindrical screen drum. A main shaft in parallel with the central axis of the screen drum is arranged inside the screen drum. The main shaft rotates in synchronization with the screen drum. A plurality of smooth shafts for connecting the main shaft with the screen drum is further arranged inside the screen drum. All the smooth shafts are sleeved with vibrating hammers which are able to slide freely. The anti-blocking rotary screen is simple in structure, reasonable in arrangement, convenient in installation, good in blockage cleaning effect, saves the time for cleaning the screen drum manually, avoids the occurrence of unnecessary human body and mechanical damages, and reduces labor intensity. The anti-blocking rotary screen can also screen materials whose water content is more than 15%. The anti-blocking rotary screen shortens the screening time, increases the production efficiency, and the anti-blocking rotary screen is stable in production operations, and can be used for years without maintenance.

Owner:沈阳科翔电力环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com