Anti-clogging hollow fiber immersed membrane component with high aeration efficiency

A technology of curtain membrane and fiber membrane, which is applied in the field of hollow fiber curtain membrane modules, which can solve the problems of reduced degree of freedom, affecting the washing effect of the top of the membrane filament, etc., and achieves the effect of high aeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

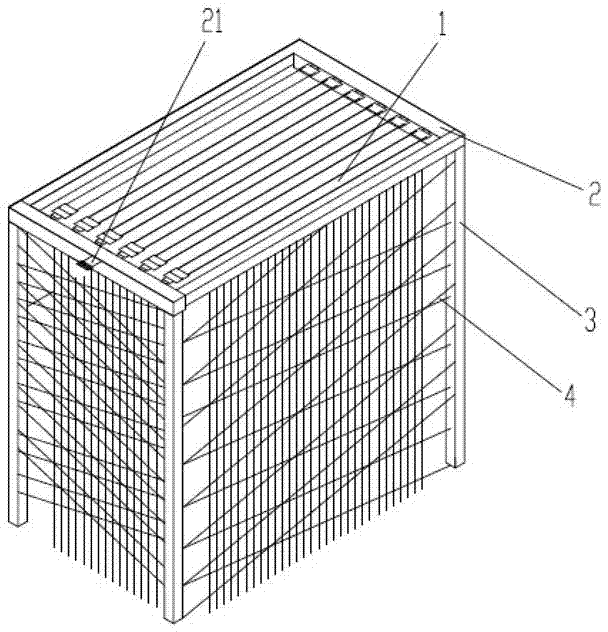

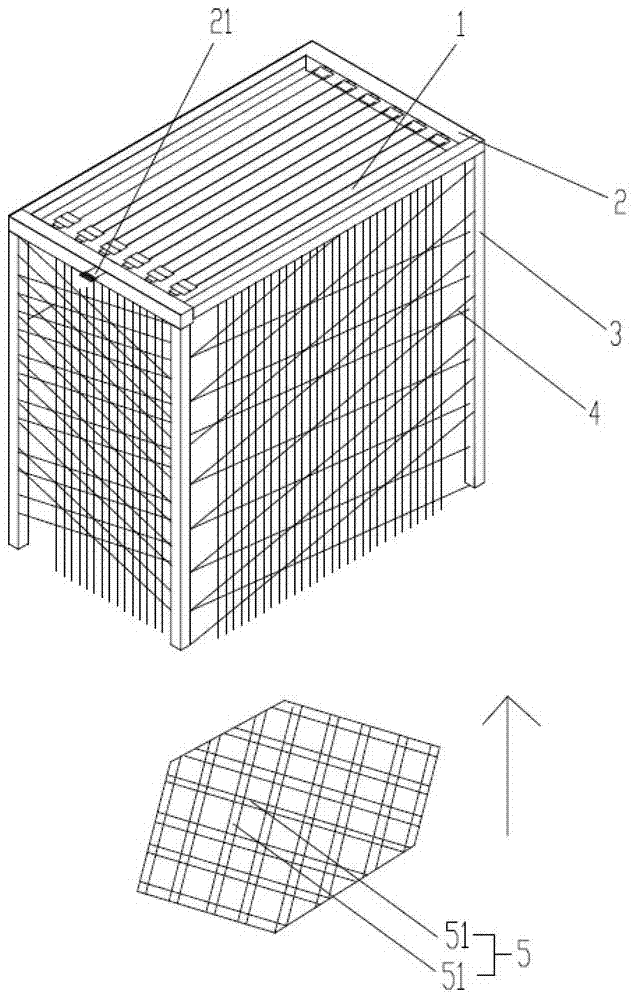

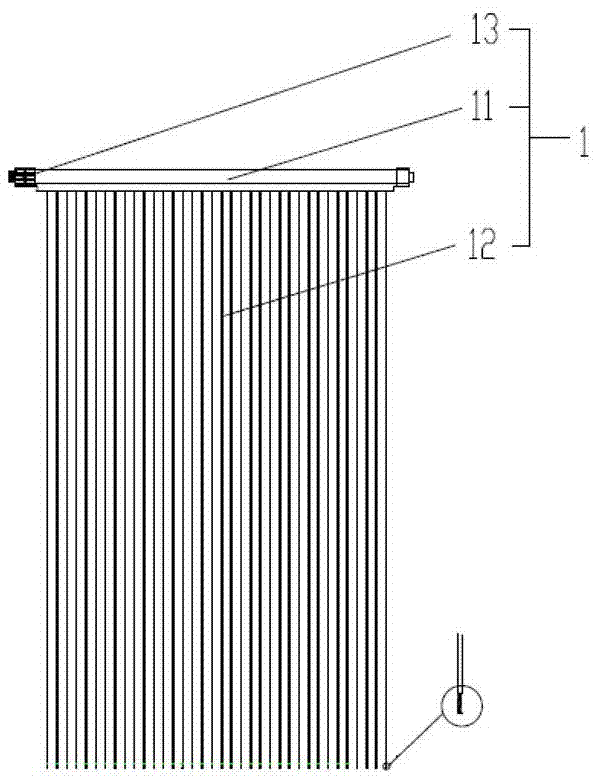

[0022] As shown in the figure, a hollow fiber curtain membrane module with anti-clogging and high aeration efficiency includes several hollow fiber membrane modules 1, hollow membrane frame 2, frame 3, anti-winding wire mesh 4 and aeration module 5. The hollow fiber membrane module 1 includes a hollow tube 11 and a hollow fiber membrane filament 12, one end of the hollow fiber membrane filament 12 is blocked, and the other end communicates with the hollow tube 11, and an inner thread connector 13 is installed on the hollow tube 11, The hollow tube 11 communicates with the hollow membrane frame 2 through the inner wire joint 13, the hollow membrane frame 2 is provided with a water outlet 21, the frame 3 is installed on the hollow membrane frame 2, and the anti-winding screen 4 is installed On the frame 3, the aeration assembly 5 is installed below the hollow membrane frame 2; the aeration assembly 5 includes a plurality of aeration tube assemblies 51, and the aeration tube assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com