High-strength thread rolling machine

A thread rolling machine and high-strength technology, applied in the field of thread rolling machines, can solve the problems of product quality decline, motor overload, and output quality reduction, and achieve the advantages of convenient manufacturing and installation, improved service life, and improved lining strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

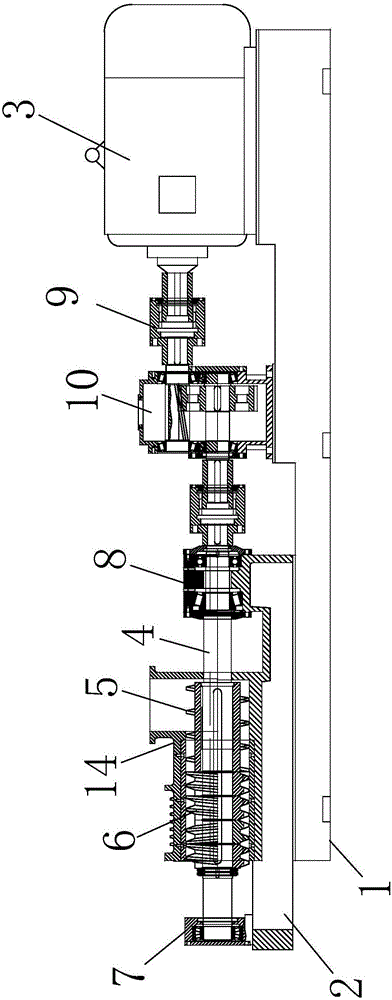

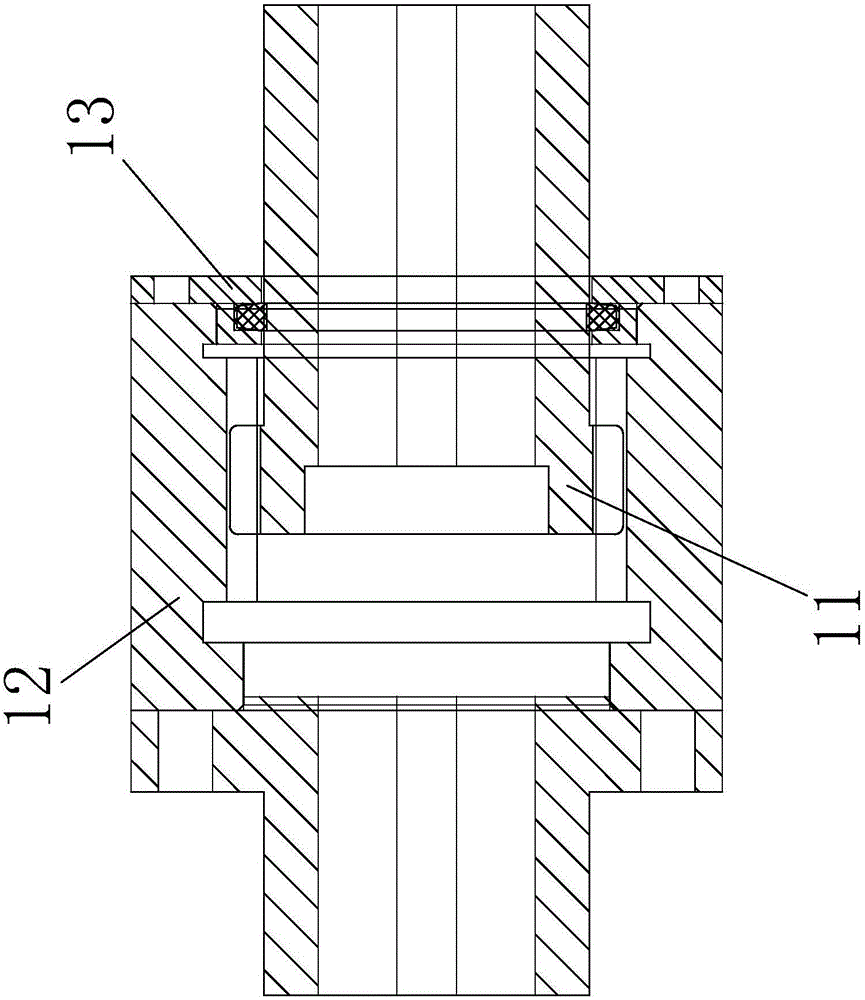

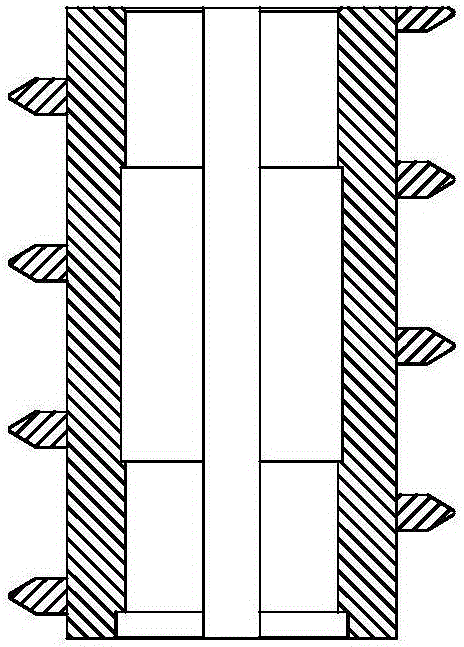

[0022] Such as Figure 1-6 As shown, a high-strength thread rolling machine includes a base 1 and a body 2. One end of the base 1 is provided with an organic body 2, and the other end is equipped with a drive motor 3. The inside of the body 2 is provided with two parallel plug-in rotating shafts 4. The feed end of the rotating shaft 4 is respectively provided with helical cutting blades 5 with opposite helical directions, and the discharge end of the plugged rotating shaft 4 is respectively provided with knife rollers 6, and the discharge end of the plugged rotating shaft 4 passes through a detachable bearing. The seat 7 is fixed on the body 2, and the feeding end of the plug-in rotating shaft 4 runs through the bearing sleeve 8 of the body 2 and is rotationally connected with the gearbox 10 through the gear coupling 9. The driving motor 3 is also connected with the gearbox through the gear coupling 9. 10 rotation connection, the gear coupling 9 is composed of an inner gear di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com