Gate lifting weight detection sensor

A technology of weight detection and sensor, applied in the field of weight sensor, can solve problems such as tension, cable winding, wire rope breaking, etc., to avoid dangerous accidents, small installation space, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] combined with Figure 1~3 The present invention is further described:

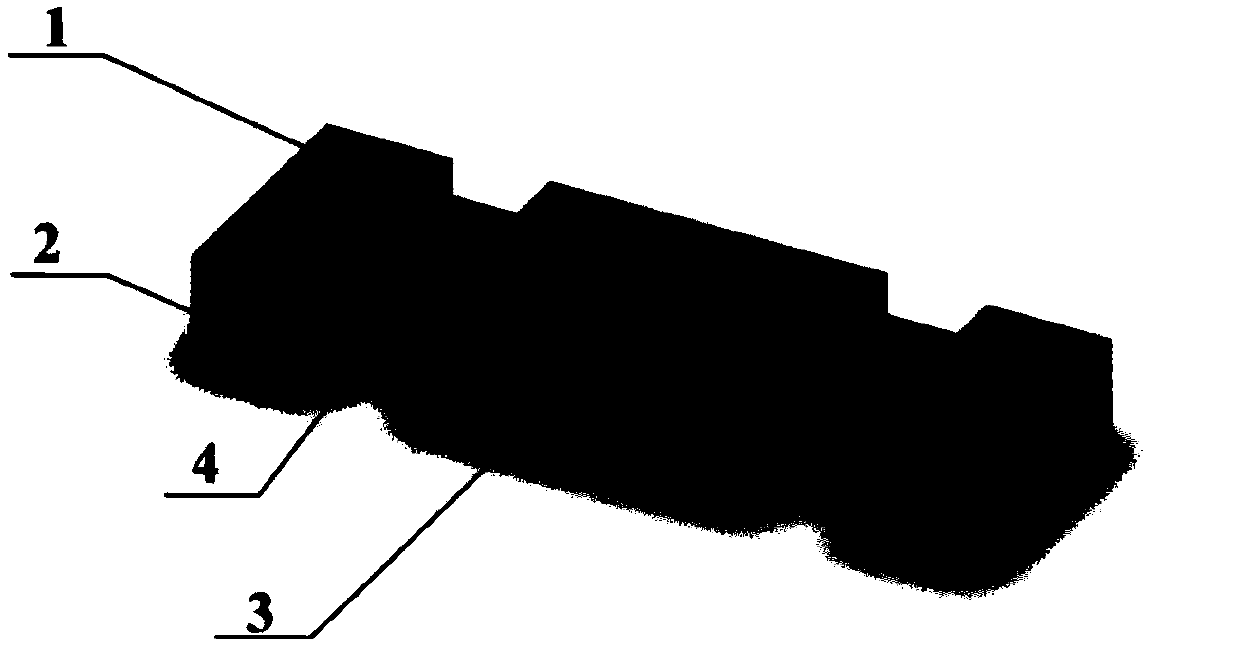

[0011] A gate lifting weight detection sensor, its structure is as follows figure 1 As shown, it includes a mounting hole 1, a support base 2, an elastic body 3 and a patch hole 4. The mounting hole 1 is located on the support base 2. There are 4 mounting holes 1, 2 on the left and right sides, For fixing the sensor, there are two supporting seats 2, one on each side of the left and right sides, supporting the elastic body 3, and there is a patch hole 4 on the left and right sides of the elastic body 3, which is used to paste the resistor type strain gauge.

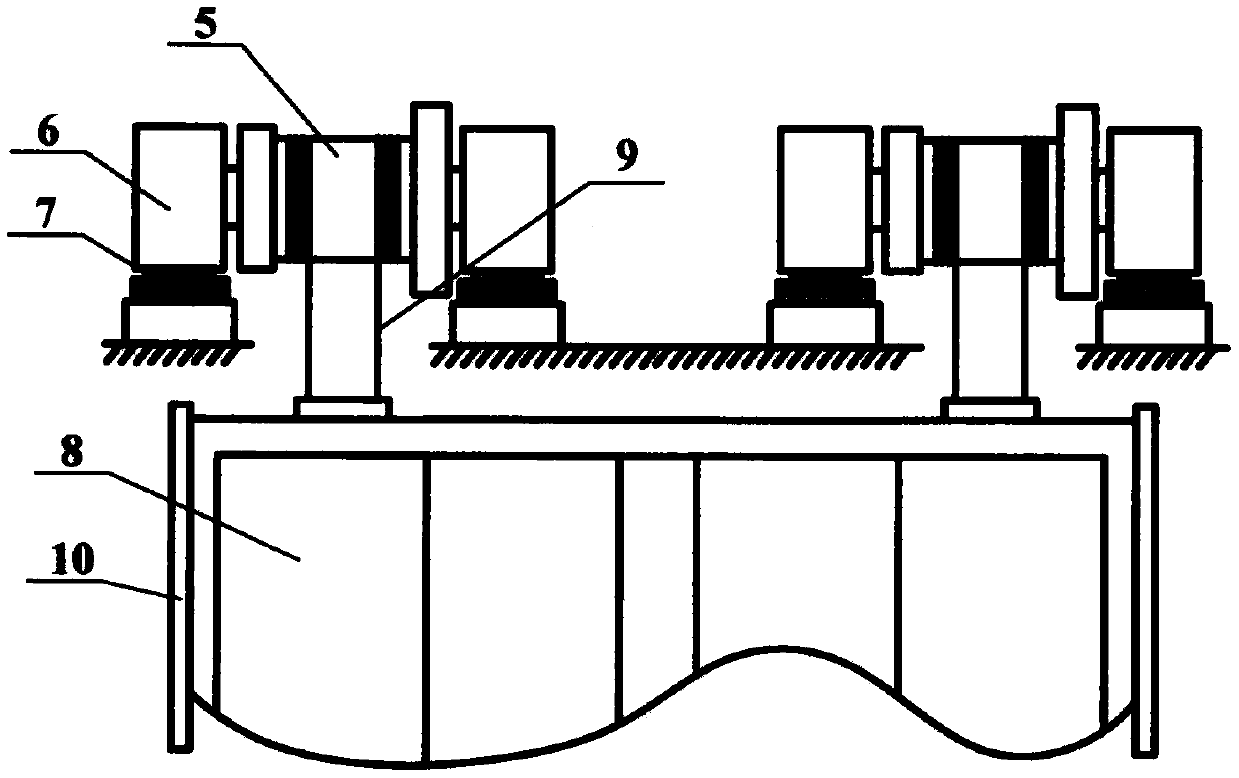

[0012] In a preferred embodiment of the present invention, the installation method of sensor is as figure 2 As shown, under the left and right bearing blocks 6 of the winch 5, a weight detection sensor 7 is placed respectively, and the steel wire rope 9 on the roller of the winch 5 is connected with the gate 8 for pulling up or down the gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com