Walking positioning, deviation correcting and collision preventing method for tire crane

A tire lifting and anti-collision technology, applied in container lifting, can solve the problems of driver fatigue, being easily affected by weather and light, and regular calibration, etc., to eliminate potential safety hazards, improve the loading and unloading efficiency of lifting containers, and reduce driver fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

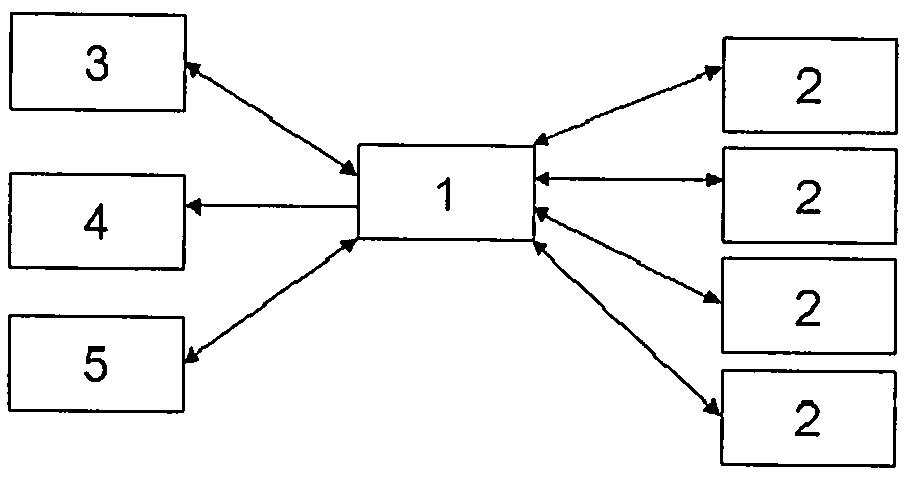

[0022] Such as figure 1 As shown, the laser scanner (2), the position management display (3), the alarm (4), and the crane PLC (5) are all connected to the computer (1). The alarm (4) can warn the tire crane driver by sound or a combination of sound and light or other methods.

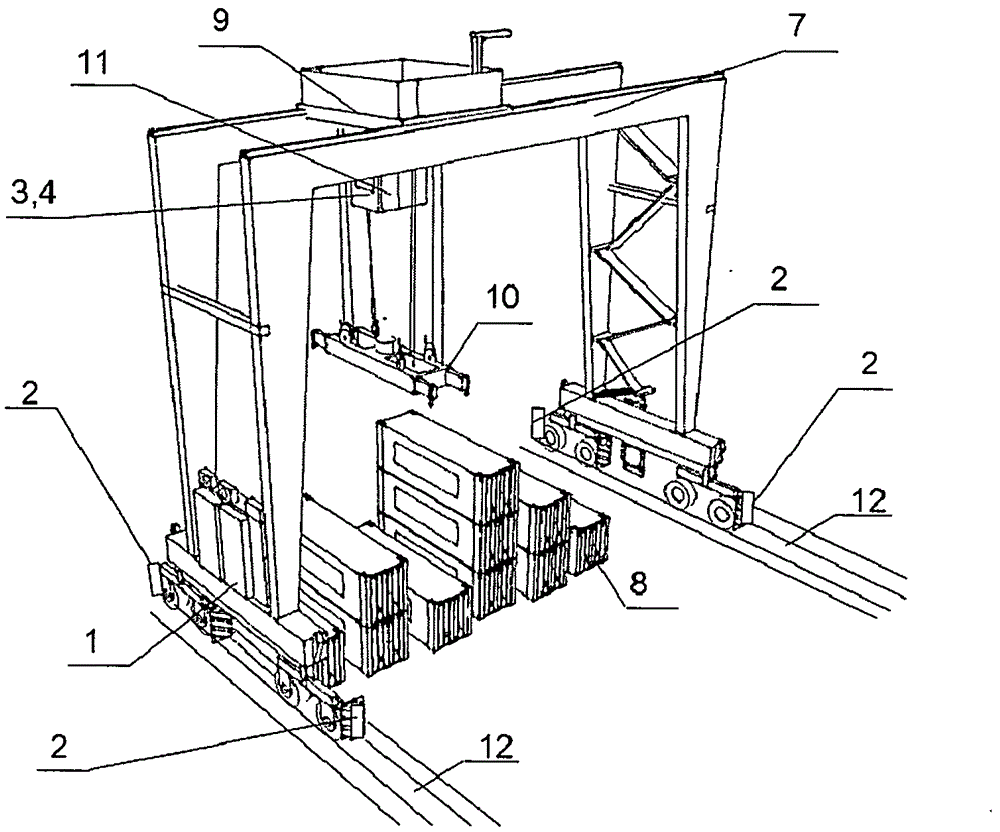

[0023] Such as figure 2 As shown, the computer (1) and the alarm (4) are installed in the electrical room, and the laser scanner (2) is installed in front of the four door leg tires of the tire crane (7), and can rotate with the rotation of the tires.

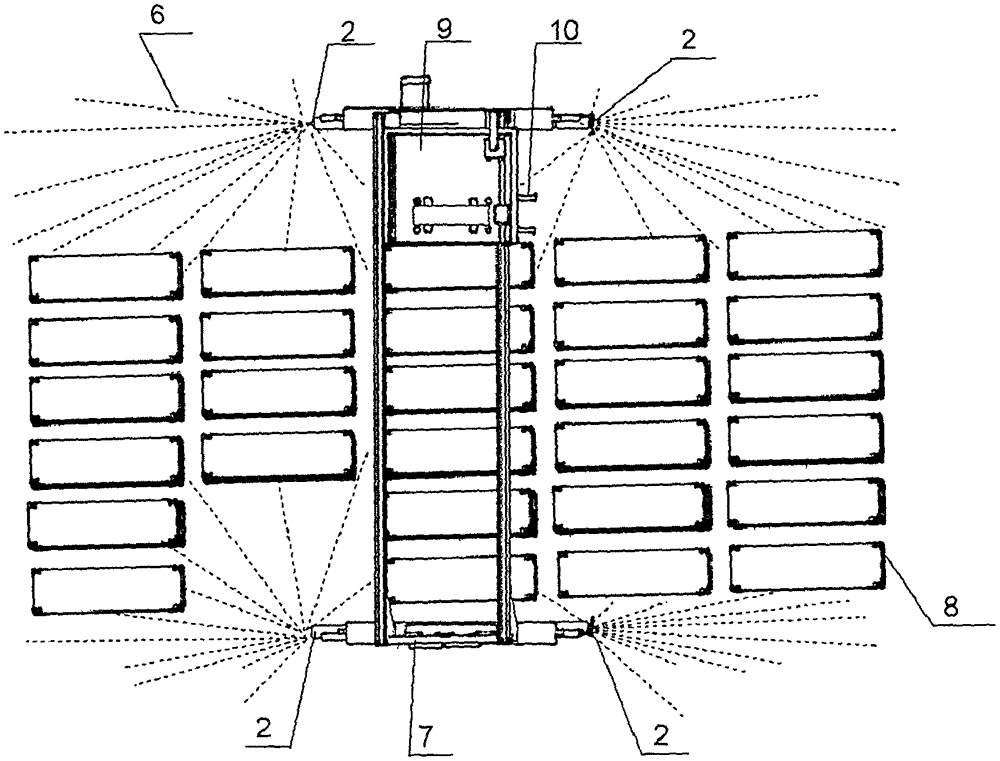

[0024] Such as image 3 As shown, after the tire crane (7) enters the yard, four laser scanners (2) can detect the sides of the containers (8) in the yard and the gaps between the containers. During the walking of the tire crane (7), if the tire crane (7) runs off the track, the laser scanning (2) detects that the distance to the side of the container (8) will increase or decrease, and the computer (1) will analyze and process the measurement data. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com