Low-consumption environment-friendly efficient phosgene synthesis technology

A technology of phosgene and chlorine, which is applied in the direction of carbonyl chloride, etc., can solve the problems of unused steam recovery, low absolute pressure of coolant space, deactivation of activated carbon catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

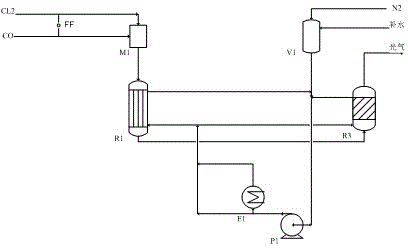

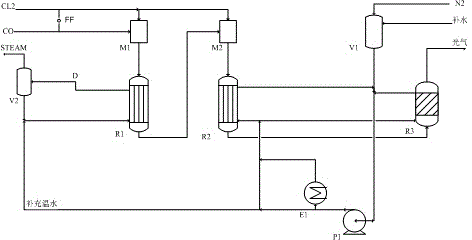

[0023] Embodiment 1: as figure 2 Shown is the proposed two-stage main reactor process for the industrial production of phosgene according to the present invention.

[0024] Known 7100kg / h of Cl 2 Accurate metering of CO with 2856kg / h (CO to Cl 2 After the volume excess ratio is 2%), all the CO and 6745kg / h (95% of the total amount of chlorine) of chlorine enter the main reactor R1 before phosgene through the mixer M1, and the CO and Cl in R1 2 The molecular ratio of the reaction is about 1.07:1, the temperature of the R1 outlet material is about 180°C, the outlet material is phosgene 8415kg / h, the unreacted CO 476kg / h, the unreacted chlorine gas 710kg / h; the R1 outlet material and the unreacted M1 After the 625kg / h residual chlorine is mixed, it enters the rear main reactor R2, and CO and Cl in R2 2 The molecular ratio of the reaction is about 1.13. The heat released by the former main reaction is 2.36Mkcal / h, which can produce 4547.76kg / h of low-pressure steam, and the c...

Embodiment 2

[0025] Embodiment 2: as figure 2 Shown is the proposed two-stage main reactor process for the industrial production of phosgene according to the present invention.

[0026] Known 7100kg / h of Cl 2 Accurate metering of CO with 2856kg / h (CO to Cl 2 After the volume excess ratio is 2%), all the CO and 6390kg / h of chlorine enter the main reactor R1 before phosgene through the mixer M1, and the CO and Cl in R1 2 The molecular ratio of the reaction is about 1.13:1, the outlet temperature of R1 is about 150°C, the outlet gas phase mixture is phosgene 7920kg / h, unreacted CO616kg / h, unreacted chlorine gas 710kg / h; R1 outlet material and the unreacted M1 After the 710kg / h remaining chlorine gas is mixed, it enters the rear main reactor R2, and CO and Cl in R2 2 The molecular ratio of the reaction is about 1.10:1. The heat released by the former main reaction is 2.22Mkcal / h, which can produce 4280.25kg / h of low-pressure steam, and correspondingly add warm water of 4280.25kg / h. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com