Ceiling fan flange and ceiling fan provided with same

A ceiling fan flange and flange technology, applied to components of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve the unavoidable problems of motor shafts, etc., to improve production efficiency and reliability Sexuality, improvement of fixed structure, and the effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

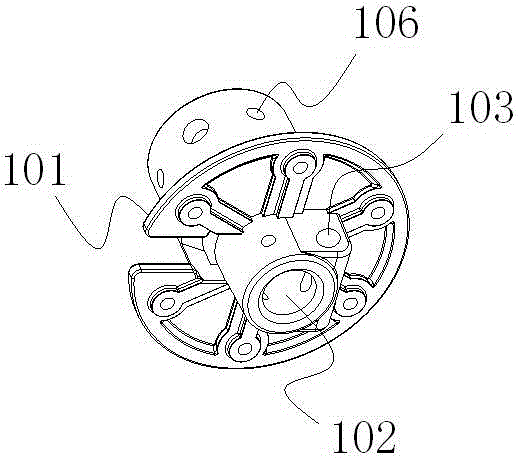

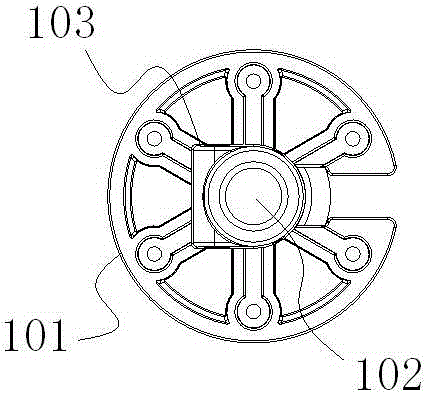

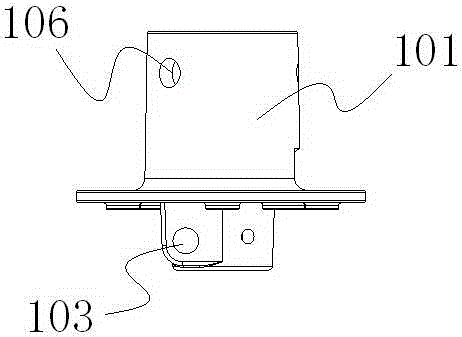

[0028] Such as Figure 1~3 As shown, the ceiling fan flange of this embodiment includes a flange body 101, and the flange body 101 is provided with a screw hole 102. The key point is that the lower part of the flange body 101 is provided with a through hole 103 orthogonal to the screw hole 102, Part of the through hole 103 communicates with the screw hole 102; the through hole 103 is fixedly equipped with a fixed pin 104, and the side of the fixed pin 104 is provided with an anti-rotation plane 105, and the anti-rotation plane 105 of the fixed pin 104 A part is located in the direction of the screw hole 102 and located in the screw hole 102 . The fixed pin 104 is secured by an "R" shaped spring 108 passing through the end of the fixed pin 104 .

[0029] Such as Figure 4~7 As shown, the ceiling fan of this embodiment includes a motor shaft 2, a motor 3, fan blades and the above-mentioned flange 1, the motor 3 is mounted on the motor shaft 2, the fan blades are mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com