Five or six gear shifting yoke bending die of automobile

A five-six-speed, automotive technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low processing accuracy, troublesome workpiece forming, low production efficiency, etc., and achieve high processing accuracy, reliable fixation, and workpiece forming convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

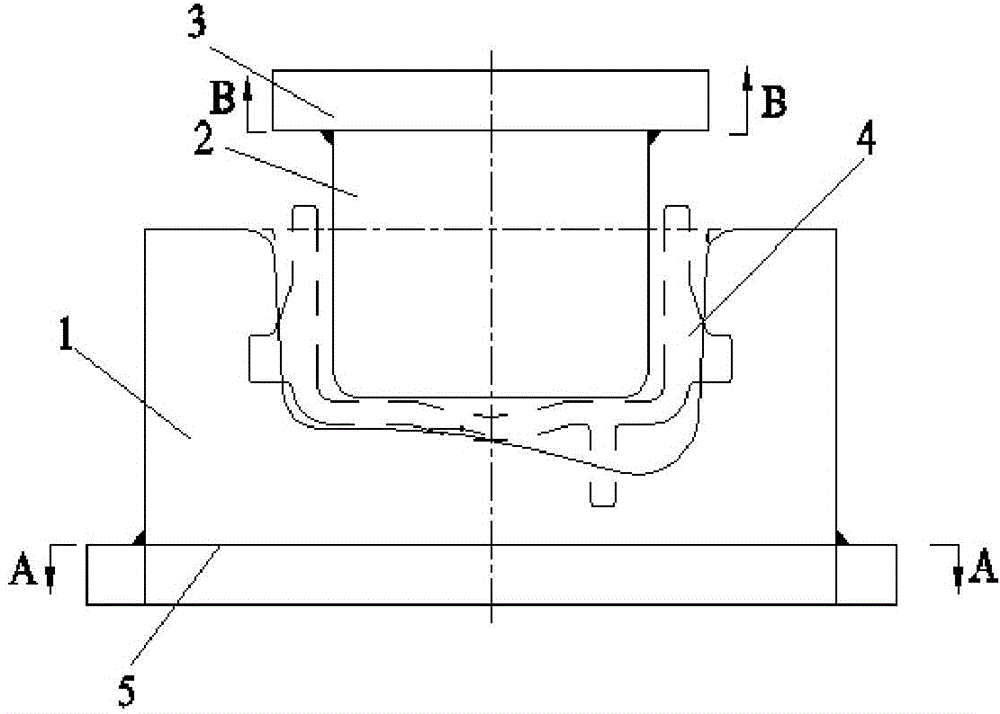

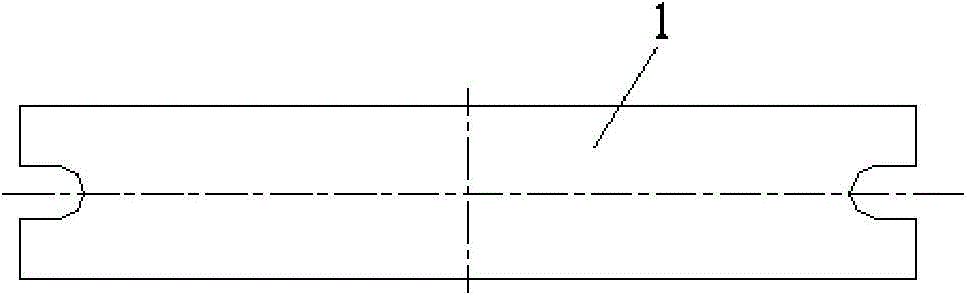

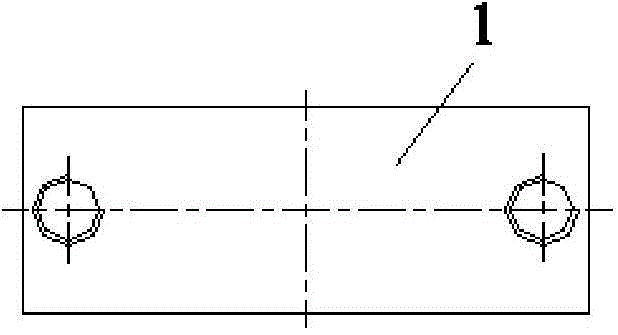

[0017] A bending mold for five-six-speed shift fork for automobiles, comprising a die 1, a punch 2, a punch fixing plate 3, a workpiece 4, and a die fixing plate 5, a counterbore is processed in the middle of the die 1, the die 1 and the die The fixed plates 5 are fixed as a whole by welding, and the connection is firm. During processing, the workpiece 4 is placed in the counterbore of the die 1, and the punch 2 forges the workpiece 4 placed in the die 1, and the punch 2 It is also fixedly connected with the punch fixing plate 3 by welding, the punch fixing plate 3 is fixed with the forging head of the forging bed, and the forging head moves up and down to drive the punch 2 to forge the blank of the workpiece 4 to form the workpiece 4. required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com