Surface fine treatment system for plastic part machining

A surface processing and processing system technology, applied in the field of plastic parts processing, can solve the problems of low grinding efficiency, unstable fixation, easy slippage, etc., and achieve the effects of high grinding efficiency, reliable fixation and good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing:

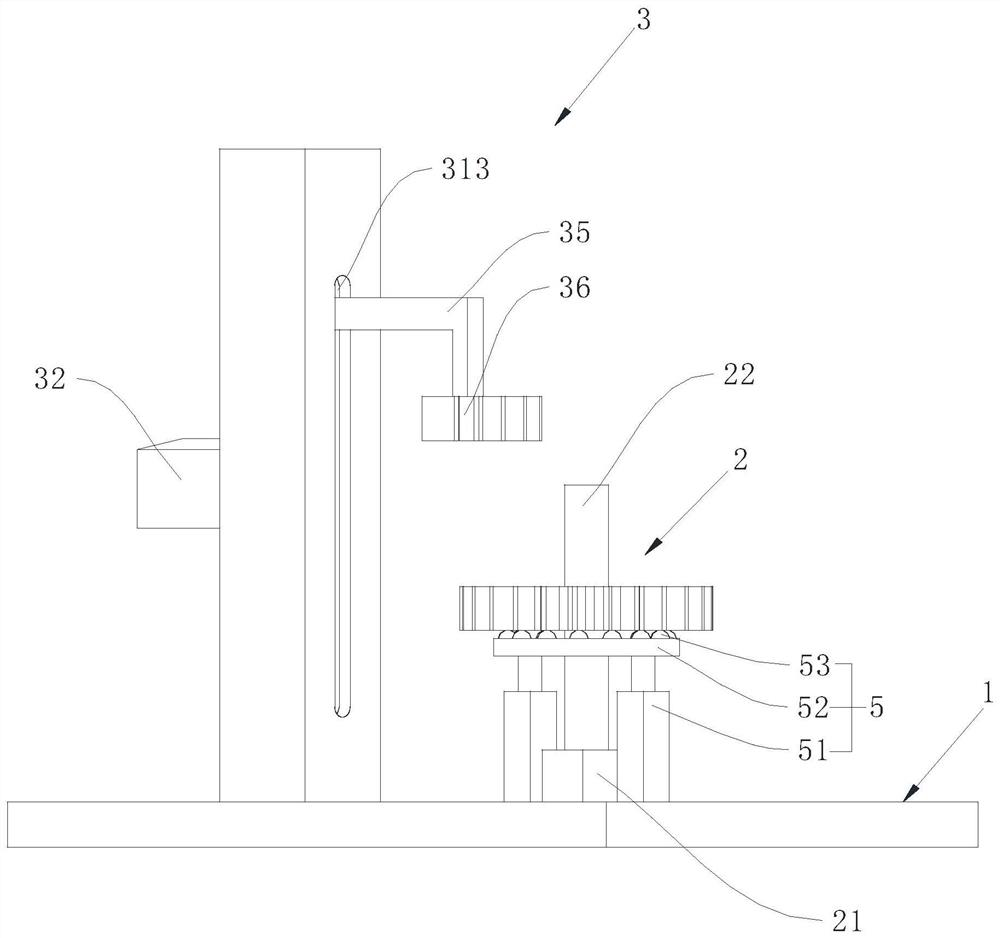

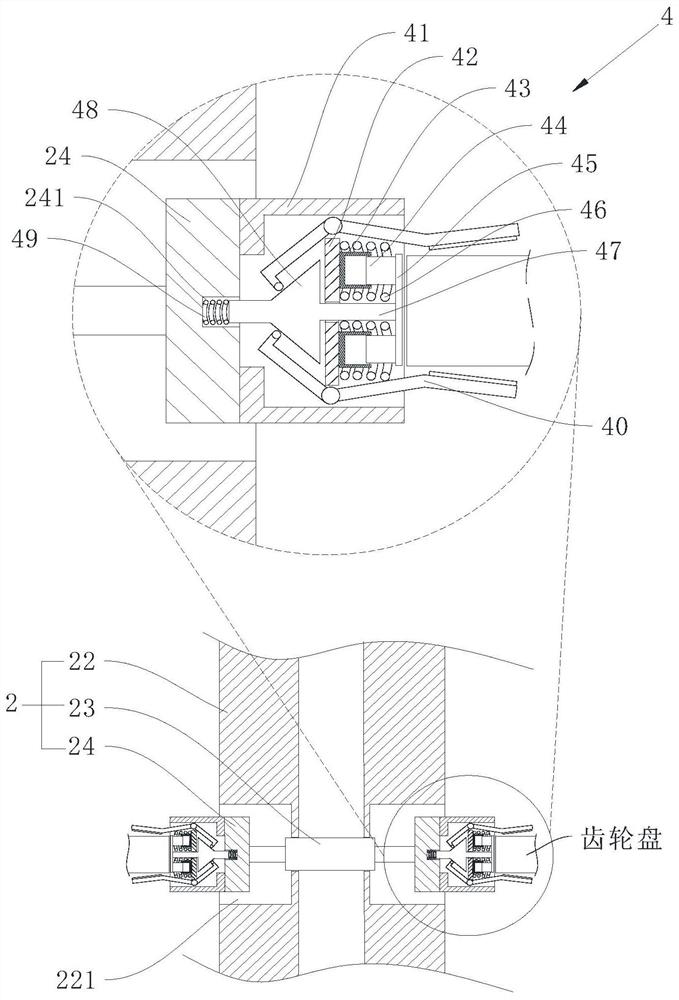

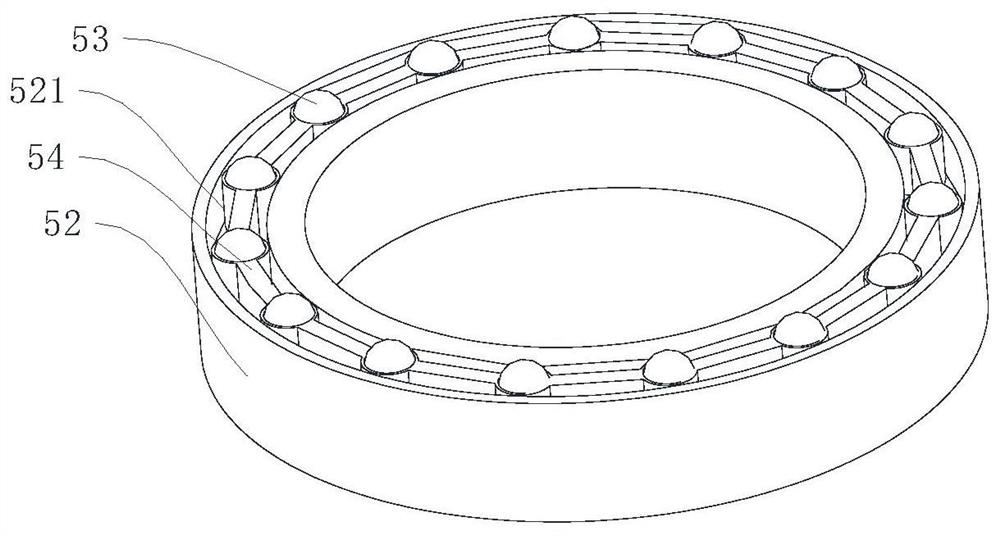

[0030] refer to figure 1 As shown, it is a fine processing system for plastic parts processing disclosed by the present invention, which includes a workbench 1, on which a fixing device 2 for fixing plastic gears to be processed and a grinding device for grinding the fixed plastic gears are arranged. Device 3, during the entire grinding operation of plastic gears, the bidirectional electric cylinder 23 can drive the fixing plate 24 to fix plastic gears with different inner hole diameters, and the grinding device 3 grinds the fixed plastic gears. The device of the present invention has a good grinding effect in grinding plastic gears, and is suitable for grinding plastic gears with relatively narrow spacing between two teeth 342, and has the effects of reliable fixing of plastic gears and high grinding efficiency.

[0031] refer to figure 1 and figure 2As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com