Method for detecting flatness of planar antennas and fast adjustable tool thereof

A technology of flatness detection and flat panel antenna, which is applied in the direction of workpiece clamping device, mechanical roughness/irregularity measurement, manufacturing tools, etc., can solve the problem of low precision and quality of flatness detection, affecting antenna performance indicators, and workload Large and other problems, to achieve the effect of improving detection efficiency and position accuracy, reducing manual workload and repeated measurement, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A flatness detection method of a panel antenna, comprising the following steps:

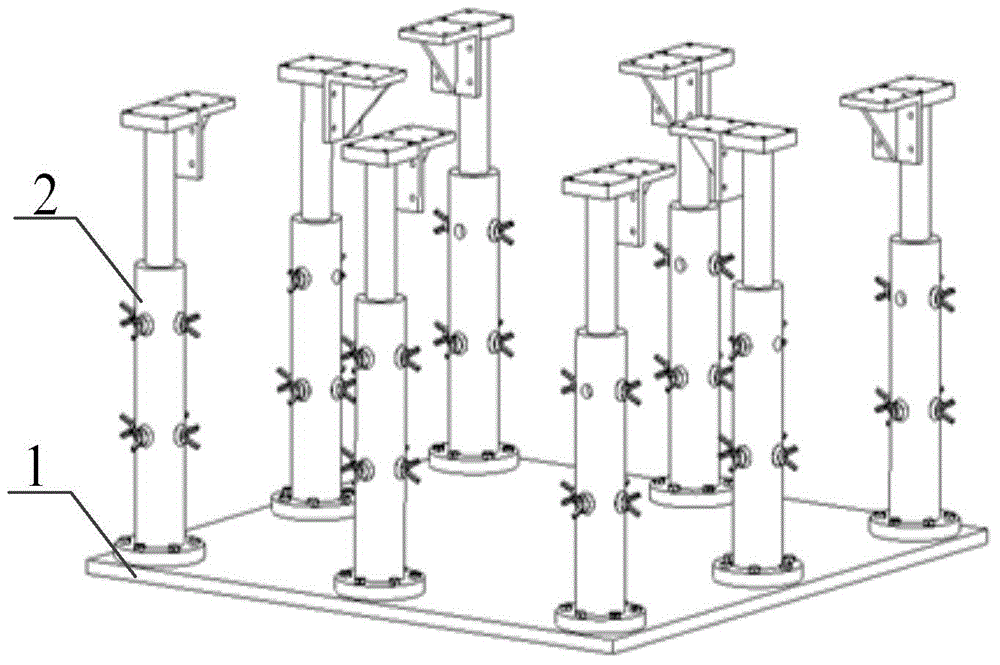

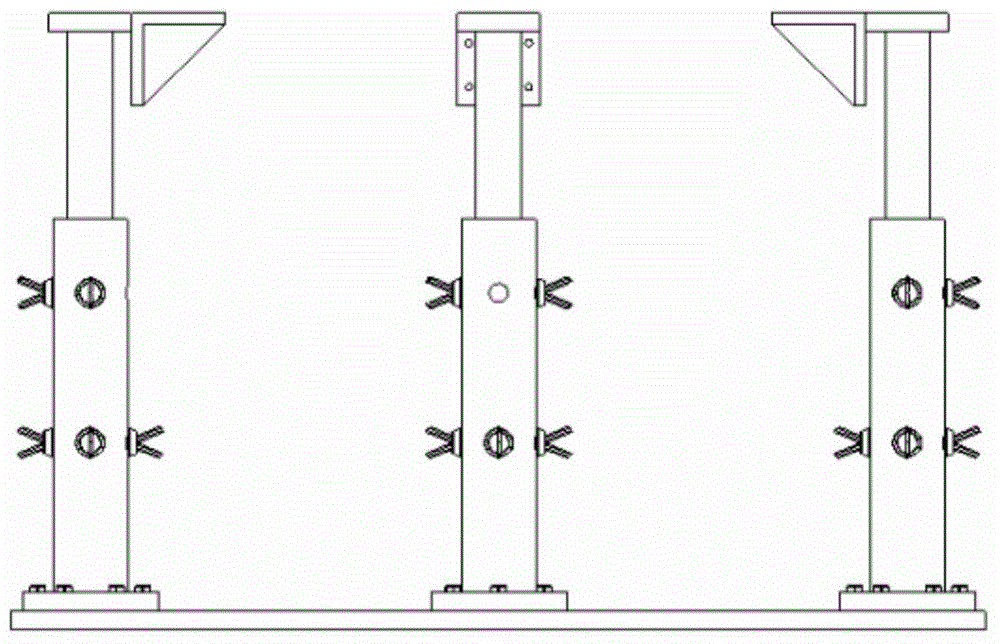

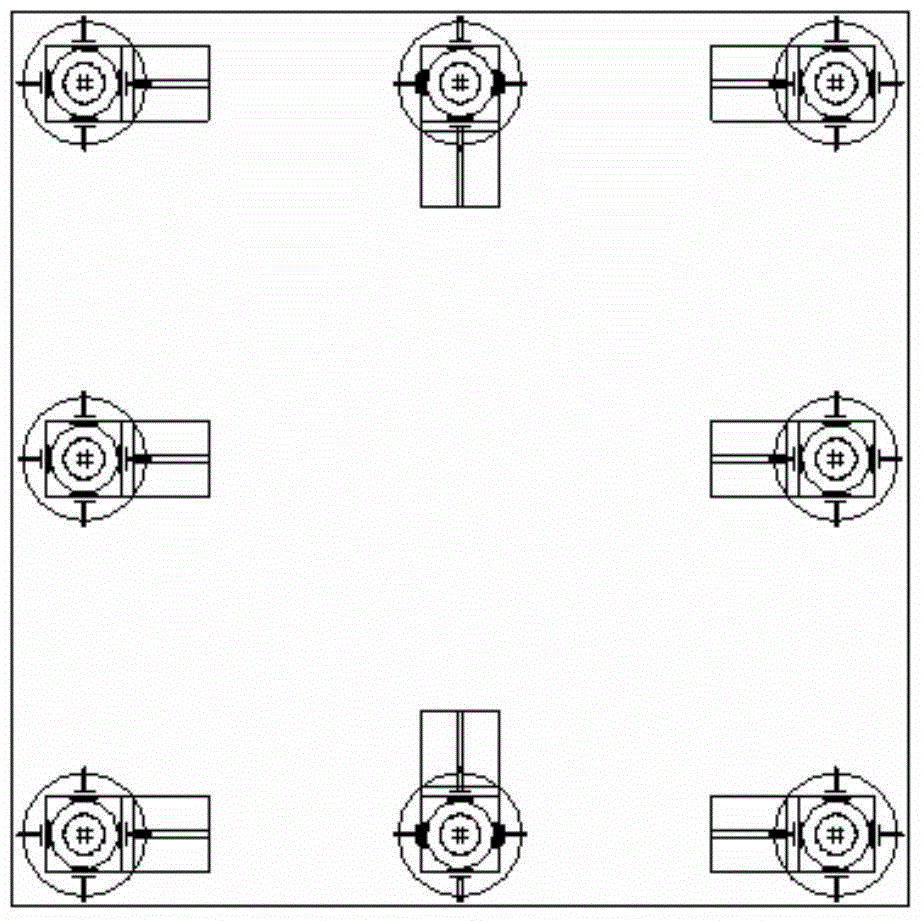

[0021] Step 1 is to take a fast adjustable tool, the speed adjustable tool includes a flat base 1, and the support structure unit 2 distributed in an array is arranged on the flat base 1, and the support structure unit 2 includes a sleeve support 204. The cylinder support 204 is provided with a support 201 and the surface of the support 201 has a scale, and the sleeve support 204 is also provided with a locking bolt 203 for fastening the support 201,

[0022] Step 2 Place the flat base 1 in a horizontal plane, adjust the top ends of each support 201 to the same height based on the scale on the surface of the support 201 and fix the support 201 with locking bolts 203,

[0023] Step 3 Place the flat panel antenna on the support member 201, and then use a measuring instrument to detect the height of the flat antenna, and calculate the flatness of the flat antenna according to the height of th...

Embodiment 2

[0025] A fast adjustable tooling for flatness detection method of flat panel antenna, comprising a flat base 1, on which support structure units 2 distributed in an array are arranged, and the support structure units 2 include sleeve supports 204 A support 201 is provided inside the sleeve support 204 and a scale is provided on the surface of the support 201 , and a locking bolt 203 for fastening the support 201 is also provided on the sleeve support 204 . In this embodiment, a support platform 205 is provided on the sleeve support member 204; a right-angle piece 202 is connected to the support platform 205 and the upper surface of the right-angle piece 202 is located on the same plane as the upper surface of the support platform 205 Inside.

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-Figure 5 As shown, the fast adjustable tooling of the present invention ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap